Energy-saving lamp manufacturing process

A manufacturing process and technology of energy-saving lamps, applied in the direction of lighting devices, light sources, semiconductor devices of light-emitting elements, etc., can solve the problems that the power supply cannot continue to provide light, achieve good social promotion, realize environmental protection, and reduce safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

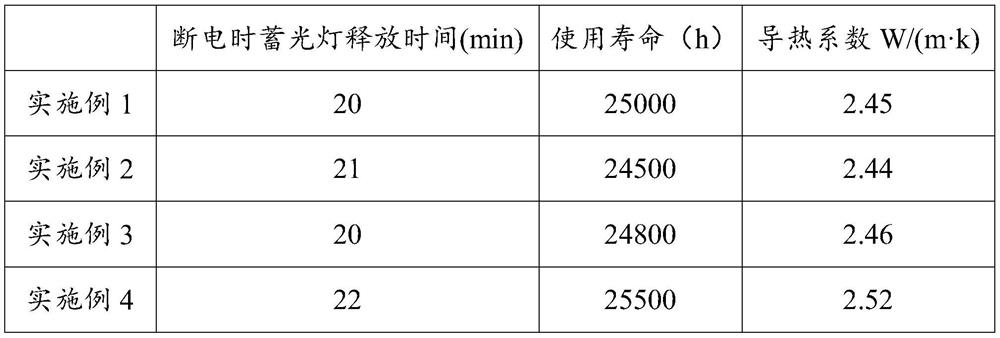

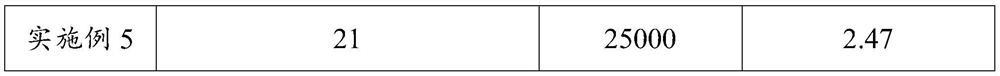

Examples

Embodiment 1

[0026] The invention provides a manufacturing process of an energy-saving lamp, which specifically includes the following steps:

[0027] Step 1: Parts preparation, using an ultrasonic cleaning machine to clean the PCB board, lamp holder, plastic mounting base, electronic component ballast, ballast substrate, upper plastic parts and lower plastic parts to be installed, and dry them for later use;

[0028] Step 2: Pressure welding, use an aluminum wire welding machine to connect the electrode to the LED core as the lead of the current, where the LED core is set in an S shape, and there are a set of filament wires at both ends of the bottom of the tube core, a total of 4 wires, The inner wall of the S-shaped tube core is coated with a mixed phosphor, and the mixed phosphor is uniformly mixed with halogen powder and rare earth three-base toner according to the weight ratio of 1:1;

[0029] Step 3: Encapsulate, protect the LED die and bonding wire with epoxy by dispensing glue;

...

Embodiment 2

[0039] The invention provides a manufacturing process of an energy-saving lamp, which specifically includes the following steps:

[0040] Step 1: Parts preparation, using an ultrasonic cleaning machine to clean the PCB board, lamp holder, plastic mounting base, electronic component ballast, ballast substrate, upper plastic parts and lower plastic parts to be installed, and dry them for later use;

[0041] Step 2: Pressure welding, use an aluminum wire welding machine to connect the electrode to the LED core as the lead of the current, where the LED core is set in an S shape, and there are a set of filament wires at both ends of the bottom of the tube core, a total of 4 wires, The inner wall of the S-shaped tube core is coated with a mixed phosphor, and the mixed phosphor is uniformly mixed with halogen powder and rare earth three-base toner according to the weight ratio of 1:1;

[0042] Step 3: Encapsulate, protect the LED die and bonding wire with epoxy by dispensing glue;

...

Embodiment 3

[0052] The invention provides a manufacturing process of an energy-saving lamp, which specifically includes the following steps:

[0053] Step 1: Parts preparation, using an ultrasonic cleaning machine to clean the PCB board, lamp holder, plastic mounting base, electronic component ballast, ballast substrate, upper plastic parts and lower plastic parts to be installed, and dry them for later use;

[0054] Step 2: Pressure welding, use an aluminum wire welding machine to connect the electrode to the LED core as the lead of the current, where the LED core is set in an S shape, and there are a set of filament wires at both ends of the bottom of the tube core, a total of 4 wires, The inner wall of the S-shaped tube core is coated with a mixed phosphor, and the mixed phosphor is uniformly mixed with halogen powder and rare earth three-base toner according to the weight ratio of 1:1;

[0055] Step 3: Encapsulate, protect the LED die and bonding wire with epoxy by dispensing glue;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com