Method for repairing metal layer photoetching process hot spot

A technology of photolithography process and repair method, which is applied in the field of repair of metal layer photolithography process hotspots, and can solve problems such as integrated circuit tape-out failure and impact on metal layer circuit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

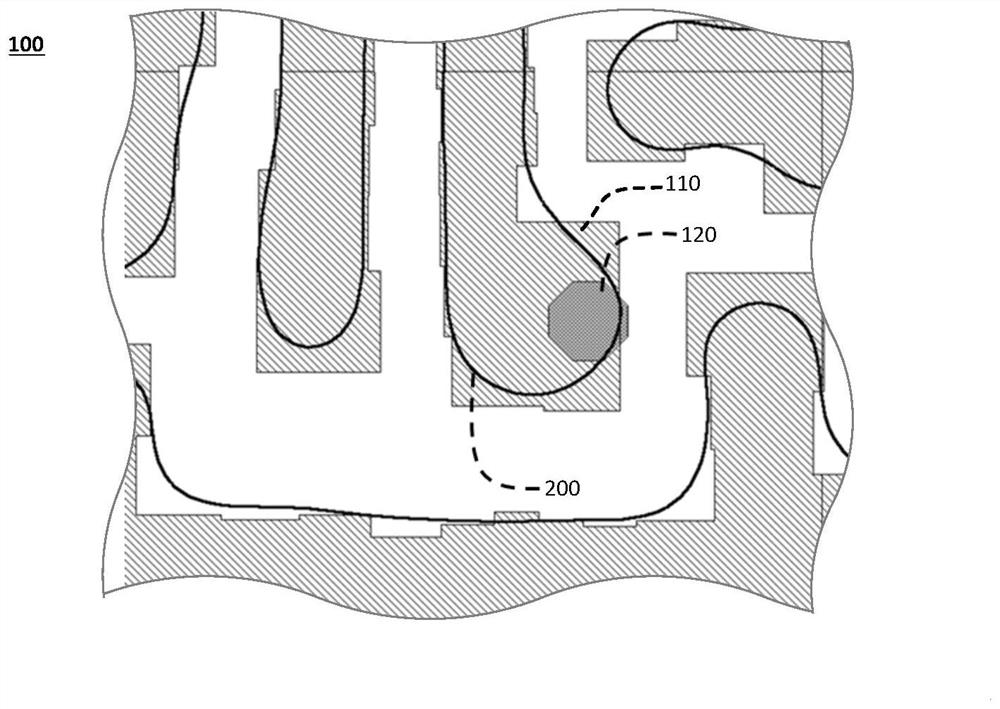

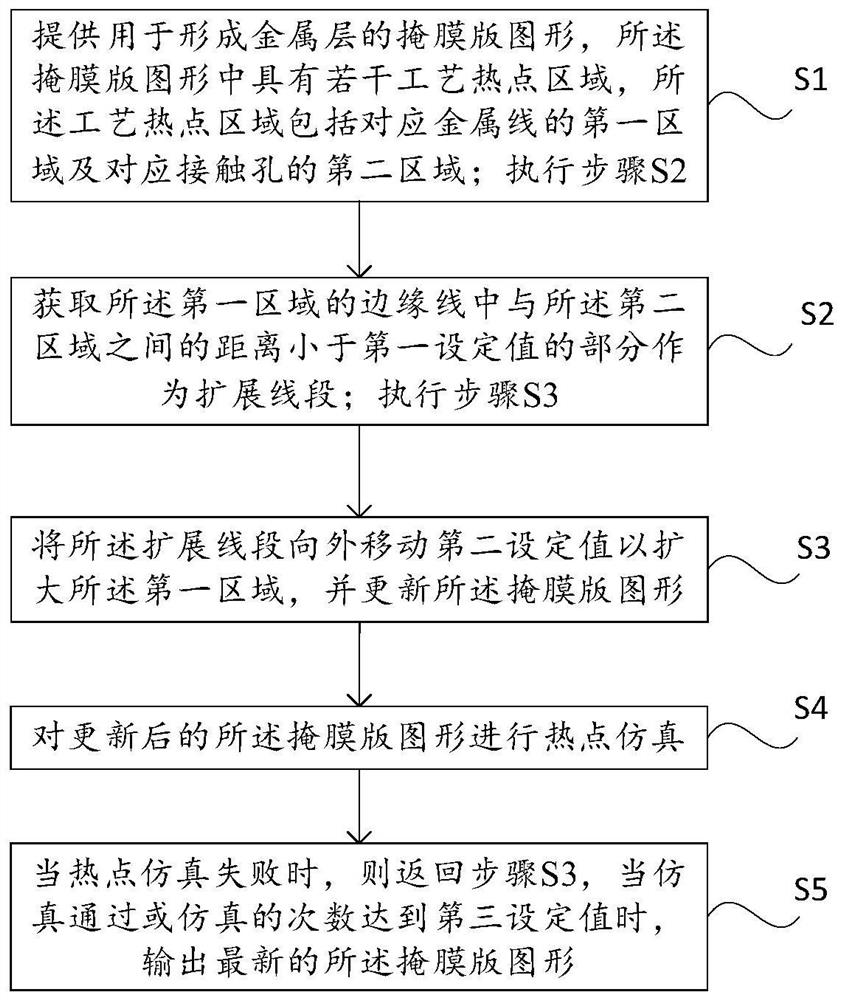

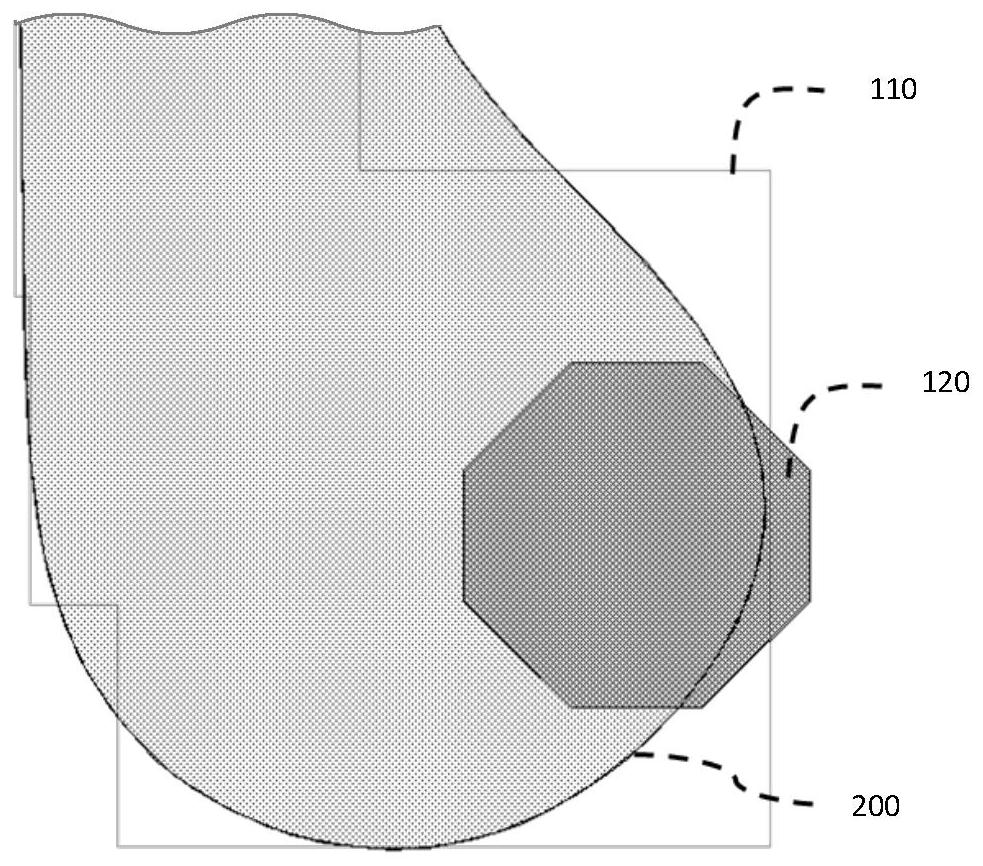

[0046] figure 1 It is a schematic diagram of the metal layer mask pattern and its simulated exposure pattern in the embodiment of the present invention. Such as figure 1 As shown in the background art, before the metal layer mask is published, hot spots in the photolithography process should be found and optical proximity repair should be performed on the metal layer mask pattern. At present, the repair method for the hot spots of the metal layer photolithography process commonly used in the industry is a model-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com