Fuel cell medium-pressure hydrogen steady-state cyclic utilization system

A fuel cell and hydrogen technology, used in fuel cells, fuel cell additives, fuel cell control, etc., can solve the problem of inability to wet the proton exchange membrane fuel cell operation performance, unable to solve the circulating pump workload, and reuse hydrogen. Low humidity and other problems, to achieve the effect of saving required costs, preventing excessive pressure, and reducing condensation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

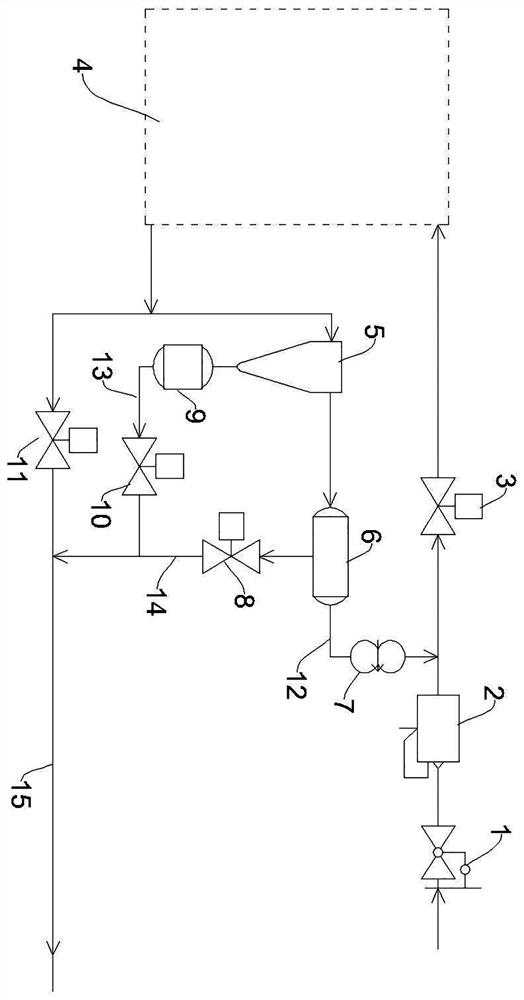

[0034] A system for steady-state recycling of medium-pressure hydrogen in a fuel cell, such as figure 1 As shown, it includes a pressure reducing valve 1, a proportional valve 2, a hydrogen inlet valve 3, a fuel cell 4, and a water vapor separator 5 connected sequentially through pipelines; the water vapor separator 5 is provided with a gas outlet and a liquid outlet, and the outlet The gas port is connected to the inlet of the hydrogen inlet valve 3 through a reuse pipeline 12, and a buffer tank 6 and a circulation pump 7 are sequentially arranged on the reuse pipeline 12; the liquid outlet is communicated with a drainage pipeline 13, And the drainage pipeline 13 is provided with a water storage tank 9 and a drainage valve 10 in sequence, and the inside of the water storage tank 9 is provided with a liquid level sensor; 14 in communication; the interface between the buffer tank 6 and the hydrogen exhaust pipeline 14 is located at the bottom of the buffer tank 6; The rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com