A test method for dew point temperature of fuel cell humidification reaction gas

A technology of reaction gas and dew point temperature, applied in fuel cells, electrical components, circuits, etc., can solve the problems of dew point temperature deviation, uneconomical, high price of dew point instrument, achieve accurate calculation results, reduce measurement cost, and simple measurement equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

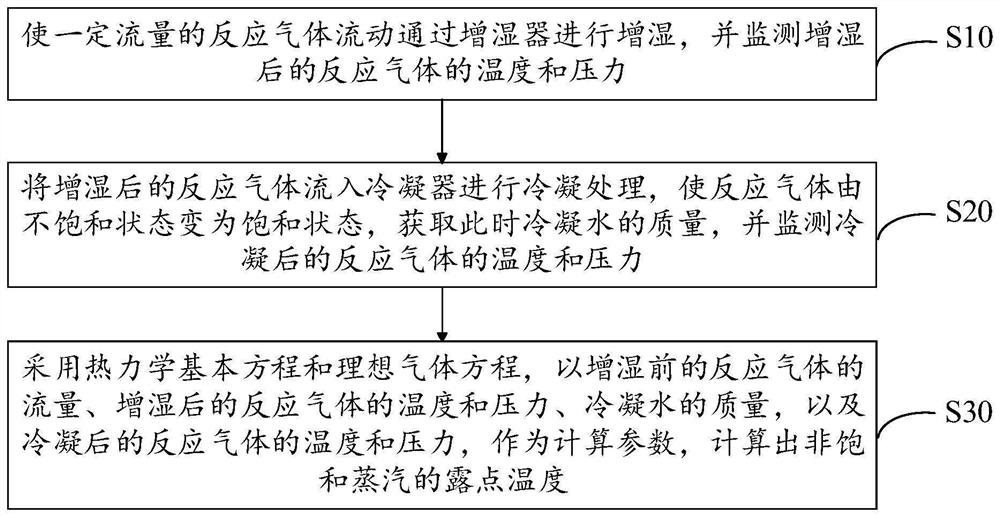

[0041] see figure 1 , the first embodiment of the present invention provides a method for testing the dew point temperature of the fuel cell humidification reaction gas, including:

[0042] S10, making a certain flow rate of reaction gas flow through the humidifier to perform humidification, and monitoring the temperature and pressure of the humidified reaction gas;

[0043] In this step, it should be noted that humidification refers to the process of increasing the humidity of the gas, which is a unit operation belonging to the process of heat and mass transfer. Generally speaking, humidification and dehumidification are used in conjunction with air conditioning to establish the required environment for production, life, and scientific experiments. In chemical production, the rapid cooling of high-temperature gas and the cooling of hot water all use direct gas-liquid contact for heat and moisture exchange. The principle is the same as that of humidification, and it is also a...

no. 2 example

[0066] In order to help understand the specific process of this program, the second embodiment of the present invention provides a complete calculation process that brings specific values into the dew point temperature test method to examine the performance of a proton exchange membrane fuel cell stack test bench in a certain working condition Point air humidification capacity, calculate its dew point value as an example,

[0067] Before calculation, record the unhumidified air flow rate S as 2504slpm, the gas pressure after humidification P1=102kpa, temperature T1=63.5°C, condense the humidified gas to a certain temperature T2=5.8°C and Pressure P2=0kpa, collect the mass of condensed liquid water m=6661g and time t=32.9min, then calculate by thermodynamics and ideal gas equation:

[0068] (1) To calculate the saturated vapor pressure of condensed gas, use the formula: get p sat 2=0.916kpa; wherein, A, B, and C are constants corresponding to different gases in Antoine's e...

no. 3 example

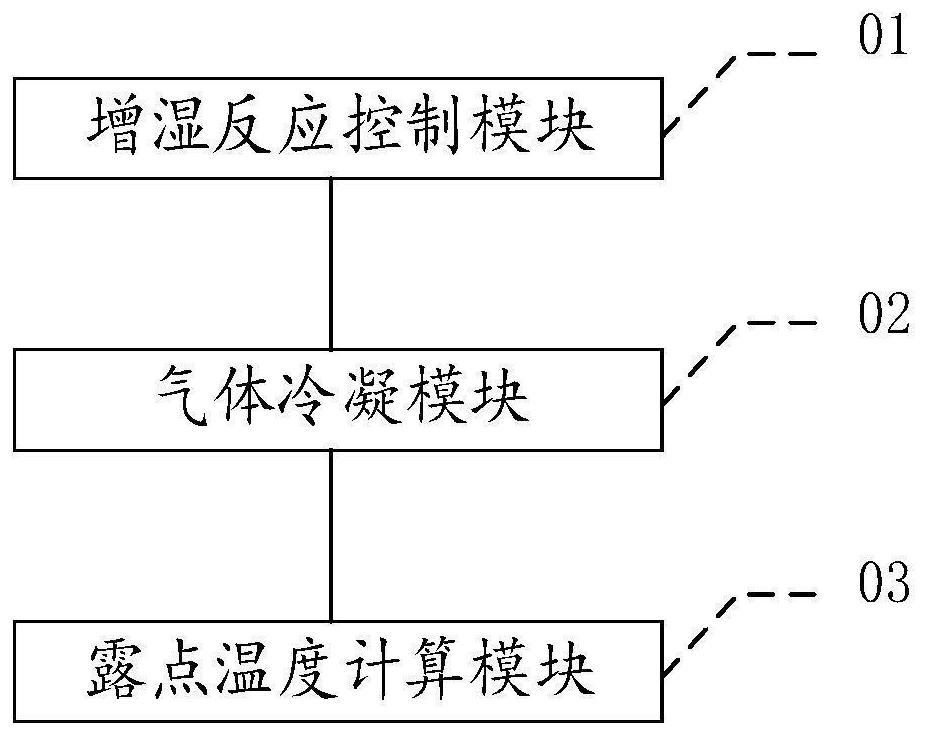

[0079] see figure 2 , the third embodiment of the present invention also provides a fuel cell humidification reaction gas dew point temperature testing system, including:

[0080]The humidification reaction control module 01 is used to make a certain flow rate of reaction gas flow through the humidifier for humidification, and monitor the temperature and pressure of the humidified reaction gas;

[0081] The gas condensation module 02 is used to flow the humidified reaction gas into the condenser for condensation treatment, so that the reaction gas changes from an unsaturated state to a saturated state, obtain the quality of condensed water at this time, and monitor the temperature of the condensed reaction gas and pressure;

[0082] The dew point temperature calculation module 03 is used to use the basic thermodynamic equation and the ideal gas equation to calculate the flow rate of the reaction gas before humidification, the temperature and pressure of the reaction gas afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com