Composite electrolyte and preparation method thereof, and composite electrode plate and battery containing composite electrolyte

A composite electrolyte, electrode electrode technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, non-aqueous electrolyte battery electrodes, etc. Impedance, high ionic conductivity, effect of avoiding short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

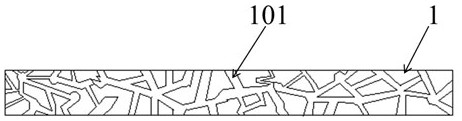

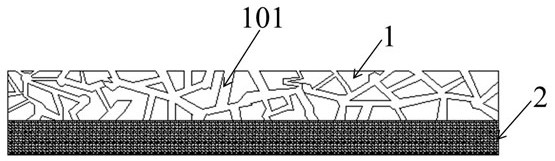

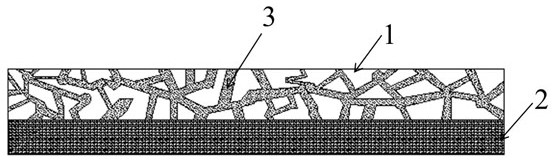

[0098] This embodiment provides a composite electrolyte, which includes a composite layer and a polymer layer; the composite layer includes a PVDF-LLZTO porous solid electrolyte layer with a porosity of 80%, an average pore diameter of 15.7 μm, and a thickness of 20 μm, and PMMA-based gel electrolyte filled in the pores of the porous solid electrolyte layer, the pores include interpenetrating pores and pores distributed on the surfaces of both sides of the porous solid electrolyte; the polymer layer is a 18 μm thick PEO-based polymer solid electrolyte layer.

[0099] The preparation method of composite electrolyte described in this embodiment comprises the following steps:

[0100] (1) Preparation of porous layer

[0101] Calculate the porosity and pore-forming dose of the porous layer according to the amount of gel electrolyte added, and the mass parts are 70 parts of LLZTO, 30 parts of PVDF, and 30 parts of LiN(SO 2 CF 3 ) 2 Mix with 25 parts of pore-forming agent ammoni...

Embodiment 2

[0108] This embodiment provides a composite electrolyte, which includes a composite layer and a polymer layer; the composite layer is a PVDF-LLZTO porous solid electrolyte layer with a porosity of 40%, an average pore diameter of 8.4 μm, and a thickness of 25 μm, and PMMA-based gel electrolyte filled in the pores of the porous solid electrolyte layer, the pores include interpenetrating pores and pores distributed on the surfaces of both sides of the porous solid electrolyte; the polymer layer is a 15 μm thick PEO-based polymer solid electrolyte layer.

[0109] The preparation method of the composite electrolyte described in this example is carried out with reference to the method in Example 1.

Embodiment 3

[0111] This embodiment provides a composite electrolyte, which includes a composite layer and a polymer layer; the composite layer is a PVDF-LLZTO porous solid electrolyte layer with a porosity of 60%, an average pore diameter of 12.1 μm, and a thickness of 18 μm, and PMMA-based gel electrolyte filled in the pores of the porous solid electrolyte layer, the pores include interpenetrating pores and pores distributed on the surfaces of both sides of the porous solid electrolyte; the polymer layer is a 10 μm thick PEO-based polymer solid electrolyte layer.

[0112] The preparation method of the composite electrolyte described in this example is carried out with reference to the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com