Structure for improving Q value of surface acoustic wave filter and manufacturing method

A technology of SAW filter and manufacturing method, which is applied in the field of electronics, can solve problems such as energy consumption, communication system communication efficiency reduction, SAW filter influence, etc., to improve Q value, good technology portability, and reduce high loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

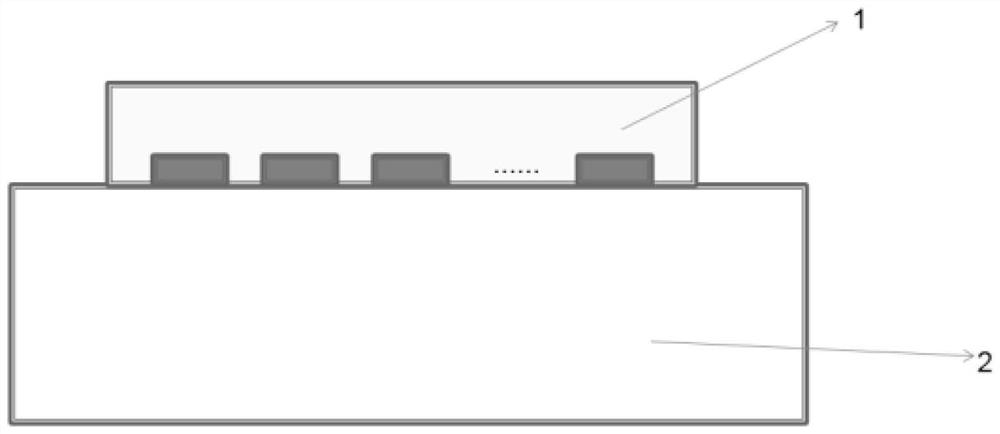

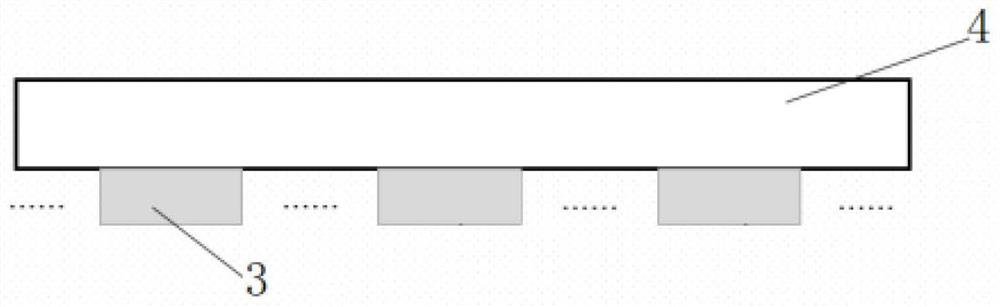

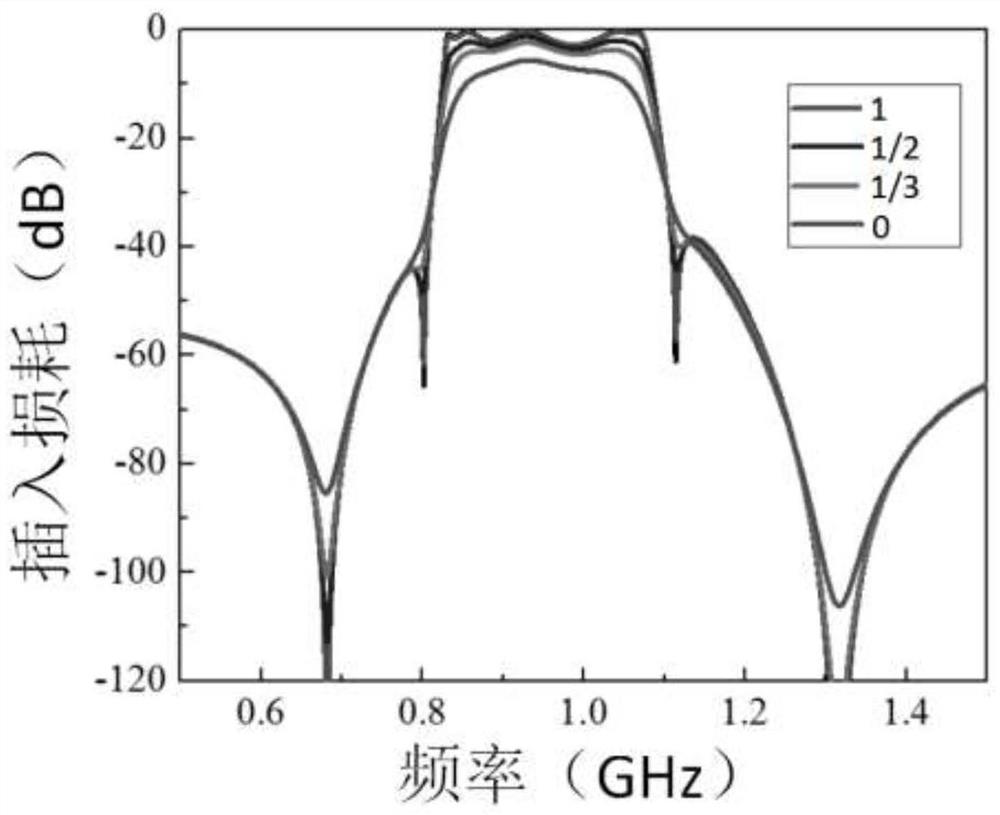

[0030] Embodiment 1: This embodiment is an SAW filter with a center frequency of 990MHz, and the transduction electrode is manufactured on a 100um lithium tantalate single crystal substrate to form a circuit in which multiple resonators are connected in series and parallel;

[0031] A structure that improves the Q value of the SAW filter (see figure 1 ), including a piezoelectric material substrate (100um lithium tantalate single crystal substrate) and a metal transducer electrode, and the metal transducer electrode is arranged on a piezoelectric material substrate (100um lithium tantalate single crystal substrate) , The metal transducer electrode includes a discontinuous metal Ni adhesion layer, a metal Au filling layer and a metal Au covering layer, and the discontinuous metal Ni adhesion layer is arranged on a piezoelectric material substrate (100um lithium tantalate single crystal substrate) On the above, the metal Au filling layer is filled in the gap of the discontinuous...

Embodiment 2

[0043] Embodiment 2: This embodiment is an SAW filter with a center frequency of 990MHz, and the transduction electrode is manufactured on a 100um lithium tantalate single crystal substrate to form a circuit in which multiple resonators are connected in series and parallel;

[0044] A structure that improves the Q value of the SAW filter (see figure 1 ), including a piezoelectric material substrate (100um lithium tantalate single crystal substrate) and a metal transducer electrode, and the metal transducer electrode is arranged on a piezoelectric material substrate (100um lithium tantalate single crystal substrate) , the metal transducer electrode includes a discontinuous metal Ti adhesion layer, a metal Ag filling layer and a metal Ag covering layer, and the discontinuous metal Ti adhesion layer is arranged on a piezoelectric material substrate (100um lithium tantalate single crystal substrate) On the above, the metal Ag filling layer is filled in the gap of the discontinuous...

Embodiment 3

[0056] Embodiment 3: This embodiment is an SAW filter with a center frequency of 990MHz, and the transduction electrode is manufactured on a 100um lithium tantalate single crystal substrate to form a circuit in which multiple resonators are connected in series and parallel;

[0057] A structure that improves the Q value of the SAW filter (see figure 1 ), including a piezoelectric material substrate (100um lithium tantalate single crystal substrate) and a metal transducer electrode, and the metal transducer electrode is arranged on a piezoelectric material substrate (100um lithium tantalate single crystal substrate) , The metal transducer electrode includes a discontinuous metal Cr adhesion layer, a metal Cu filling layer and a metal Cu covering layer, and the discontinuous metal Cr adhesion layer is arranged on a piezoelectric material substrate (100um lithium tantalate single crystal substrate) On the above, the metal Cu filling layer is filled in the gap of the discontinuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com