Passive Q-switched all-fiber laser

An all-fiber and laser technology, applied in the field of lasers, can solve the problems of increasing system loss and complexity, increasing system cost and energy consumption, and achieving the effects of improving stability, reducing high loss, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

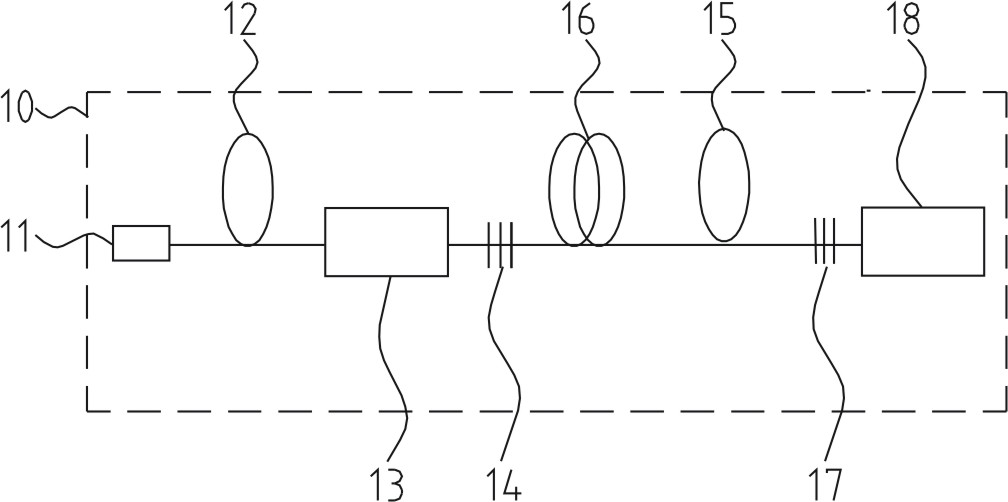

Embodiment 1

[0022] The structural schematic diagram of the passive Q-switched all-fiber laser of this embodiment is as follows figure 1 As shown, the passively Q-switched all-fiber laser is only composed of an oscillation stage 10, and the oscillation stage 10 is composed of a pump source 11, a pump protector 12, a coupler 13, a first grating 14, and a first doped fiber 16 arranged in sequence. , a Q-switching element 15, a second grating 17 and an isolator 18, wherein the pumping source 11 is a single-mode semiconductor laser with pigtail output. Pump protector 12 is Sm 3+ Saturable absorber fiber, using Sm 3+ The absorption characteristics of the filter filter out the ASE light generated by the first doped fiber 16 in the resonant cavity to complete the protection of the pumping source 11. The coupler 13 is used to couple the single-mode signal light into the resonant cavity. The first grating 14 is an FBG grating, which has the characteristics of high transparency to pump light and ...

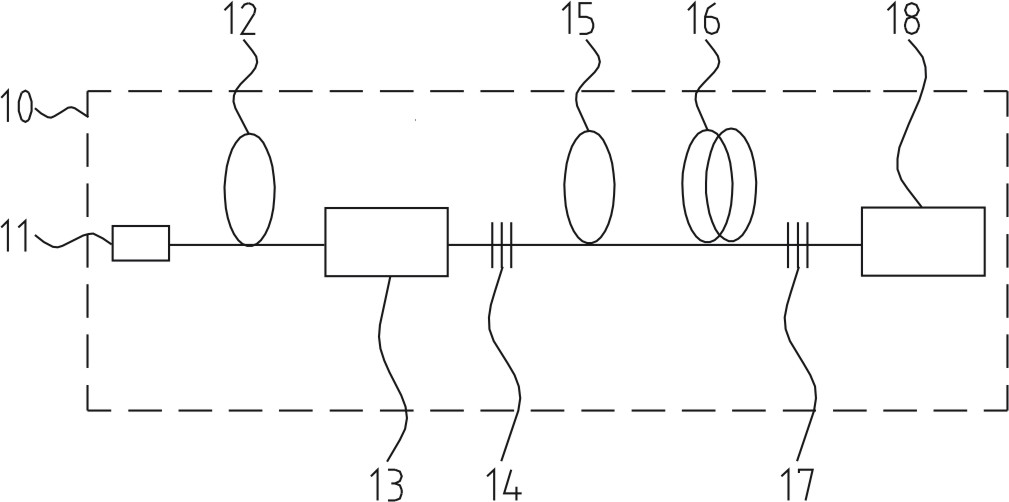

Embodiment 2

[0025] Such as figure 2 As shown, the difference from Embodiment 1 is that the Q-switching element is immediately in front of the first doped fiber. Compared with Embodiment 1, the output power of the pulse signal obtained in this embodiment is smaller and the pulse period is longer.

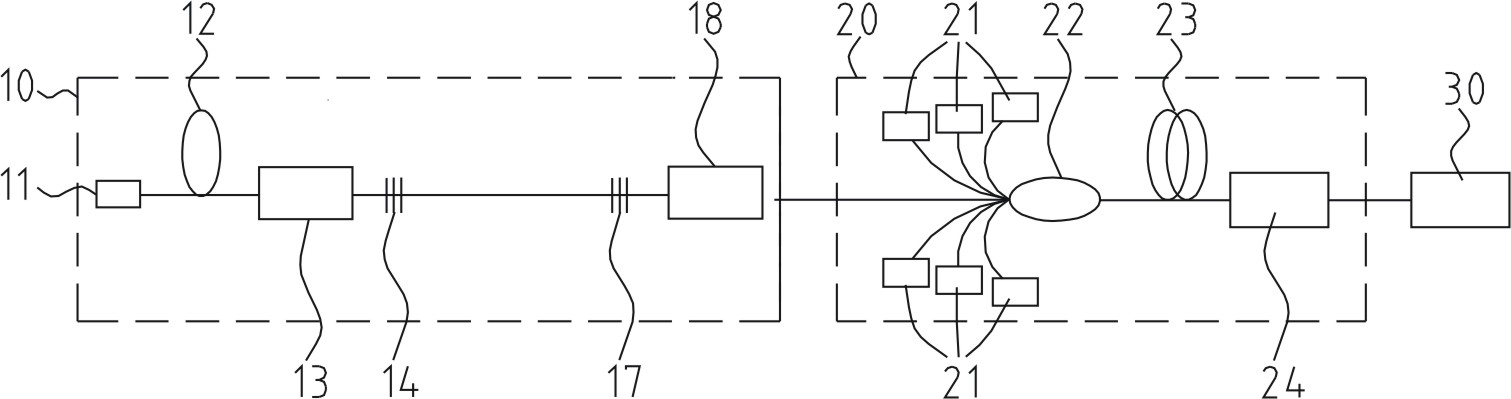

Embodiment 3

[0027] Such as image 3 As shown, the difference from Embodiment 1 is that a power amplification stage 20 is provided after the oscillation stage to amplify the power of the pulsed laser output from the oscillation stage and then output it. The power amplification stage 20 is composed of a pumping source group 21, a beam combiner 22, a second doped fiber 23 and an isolator 24, wherein the pumping source group 21 can use a laser diode with a tail output, and its selection mainly considers the second The absorption characteristics of doped fibers and the stability of the system. The beam combiner 22 is a (n+1)*1 beam combiner including (1+1)*1, (2+1)*1, (6+1)*1, etc., and the optical fiber at the pump end and the pump source The pigtails of the group 21 are matched, the signal input end needs to match the output fiber of the oscillator stage, and the signal output end fiber needs to match the second doped fiber 23, so that the system can obtain the best transmission characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com