General insulation matte black electron gravure printing ink for PET and PI films and preparation method

A gravure printing ink and electronic technology, applied in the field of ink, can solve the problems of increasing production costs, troublesome work in the use or processing of ink, and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

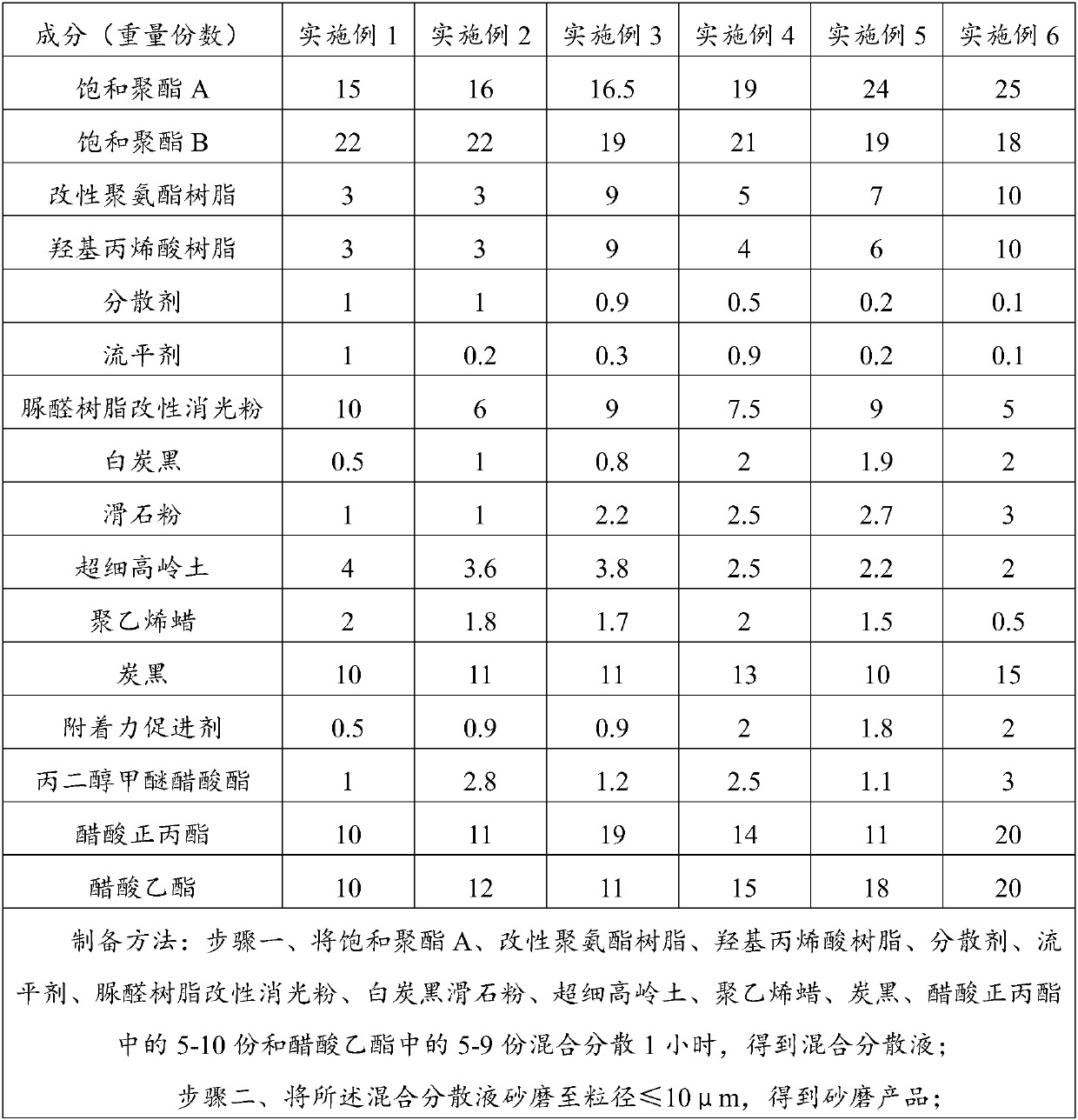

[0096] In addition, in order to solve the problems referred to above, the present invention also provides a kind of preparation method of PET and PI film general insulation dumb black electronic gravure printing ink, comprises the steps:

[0097]Step 1, 10-30 parts of saturated polyester A, 1-15 parts of modified polyurethane resin, 1-20 parts of hydroxyl acrylic resin, 0.1-2 parts of dispersant, 0.1-2.5 parts of leveling agent, 3-10 parts of urea-formaldehyde resin modified matting powder, 0.3-3 parts of white carbon black, 0.5-5 parts of talc, 1-5 parts of superfine kaolin, 0.5-3 parts of polyethylene wax, 8-20 parts Parts of carbon black, 5-10 parts of 10-20 parts of n-propyl acetate and 5-9 parts of 10-20 parts of ethyl acetate were mixed and dispersed for 1 hour to obtain a mixed dispersion;

[0098] Step 2, sand-milling the mixed dispersion to a particle size of ≤10 μm to obtain a sand-milled product;

[0099] Step 3, adding 15-30 parts of saturated polyester B, 0.3-3 p...

Embodiment 1

[0108] According to the parts by weight of the ingredients in Table 1, and according to the preparation method in Table 1, the ingredients in Example 1 were used to produce a general-purpose insulating matte black electronic gravure ink for PET and PI films.

Embodiment 2

[0110] According to the parts by weight of the ingredients in Table 1, and according to the preparation method in Table 1, the ingredients in Example 2 were used to produce a general-purpose insulating matte black electronic gravure ink for PET and PI films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com