contact microphone

A microphone and contact technology, which is applied in the direction of sensors, bone conduction transducer hearing equipment, active noise cancellation hearing equipment, etc., can solve the problems of poor anti-noise effect, large volume, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

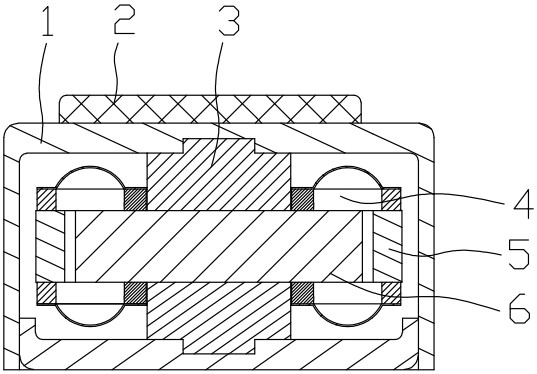

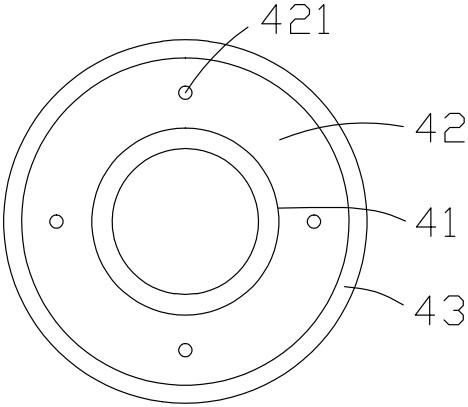

[0036] refer to Figure 1 to Figure 6 , the first embodiment of the present invention provides a contact microphone, including a housing 1, a circuit board 2 and a support block 3 placed inside the housing 1, a suspension 4, a reverse induction coil assembly 5 and a magnet 6. The circuit board 2 is arranged on the top of the housing 1, the support block 3, the suspension 4, the reverse induction coil assembly 5 and the magnet 6 are all arranged coaxially, and the reverse induction coil The component 5 is connected to the circuit board 2 and is set outside the magnet 6. The reverse induction coil component 5 includes an upper coil 511 and a lower coil 512 that are reversely wound and connected together. The magnet 6 passes through the support The block 3 is fixedly installed in the housing 1, and the two groups of suspension parts 4 are sleeved on the support block 3, and are arranged symmetrically at the upper and lower ends of the magnet 6, and the two groups of the suspensio...

Embodiment 2

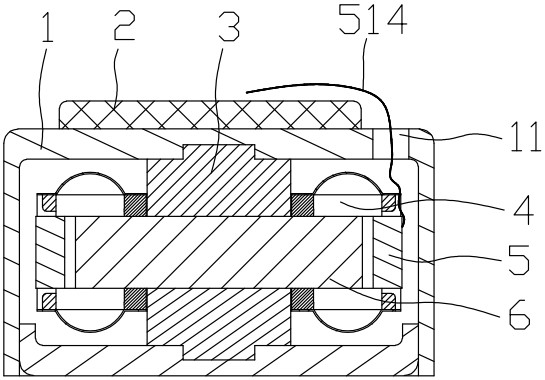

[0049] refer to Figure 7 , the second embodiment of the present invention provides a contact microphone, its implementation content is basically the same as that of embodiment 1, the difference is that: the second lead wire 514 is outside the reverse induction coil assembly 5, and the first The two lead wires 514 pass through above the connecting body 42, are pulled by glue, and fixed on the inner fixing ring 41 with glue, and then pass through the lead hole 11 of the housing 1 and the threading hole 21 of the circuit board 2 Go out and spot weld on the circuit board 2.

Embodiment 3

[0051] refer to Figure 8 , the third embodiment of the present invention provides a contact microphone, its implementation content is basically the same as that of embodiment 1, the difference is that: the second lead wire 514 is inside the reverse induction coil assembly 5, and the first Two lead wires 514 pass below the connecting body 42, the second lead wire 514 is in an arc shape, passes through the magnet 6 and is bonded to the magnet 6 by glue, and then passes through the inner fixing ring 41 The first balance hole 411 finally passes through the lead wire hole 11 of the housing 1 and the wiring hole 21 of the circuit board 2 , and is spot welded on the circuit board 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com