Self-heating low-temperature smoke cartridge

A self-heating and pod technology, applied in tobacco and other fields, can solve problems such as insufficient smoke release, narrow heating range, uneven heating of cigarettes, etc., to meet psychological and physiological needs, ensure battery life, and wide carbonization range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

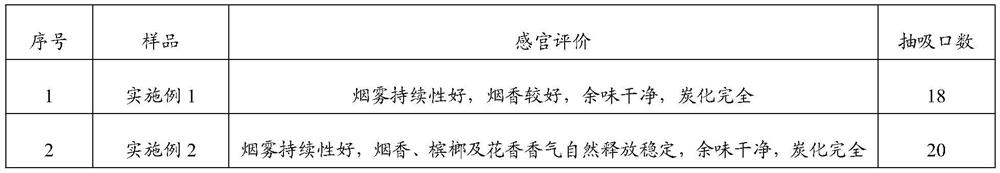

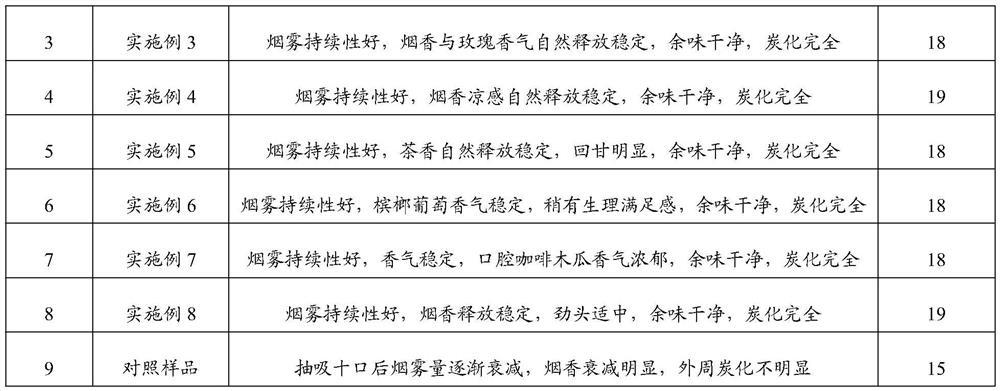

Examples

Embodiment 1

[0052] Example 1: Self-heating low-temperature cartridge of the present invention

[0053] The implementation mode of this embodiment is as follows:

[0054] The self-heating low-temperature pod is composed of a smoke-generating section, a cooling section and a filter section connected in sequence; the smoking section is composed of a self-heating material, a smoking Mixed; of which:

[0055] The self-heating material is aluminum sold under the trade name nano-aluminum powder by Guangzhou Hongwu Material Technology Co., Ltd., and its particle size is a nano-metal material of 215nm; the self-heating material has a distribution density of 0.09g / cm 3 Uniformly distributed in the smoking flavor producing material, its content is 80% by weight of the smoking flavor producing material.

[0056] The smoke-flavoring material is a mixture of flue-cured tobacco raw materials, tobacco extract sold under the trade name Yunyan Absolute Oil by Guangzhou Pinyan Food Technology Co., Ltd., a...

Embodiment 2

[0062] Example 2: Self-heating low-temperature cartridge of the present invention

[0063] The implementation mode of this embodiment is as follows:

[0064] The self-heating low-temperature pod is composed of a smoke-generating section, a cooling section and a filter section connected in sequence; the smoking section is composed of a self-heating material, a smoking Mixed; of which:

[0065] The self-heating material is an aluminum-magnesium alloy sold under the trade name nano-aluminum-magnesium alloy by Guangzhou Hongwu Material Technology Co., Ltd., and its particle size is a nano-metal material of 285nm; the self-heating material is distributed in a density of 0.11g / cm 3 Uniformly distributed in the smoking flavor-producing material, its content is 100% by weight of the smoking flavor-producing material.

[0066] The smoking and aroma-producing material is made of air-dried tobacco and flue-cured tobacco raw materials and betel nut non-smoky raw materials in a proportio...

Embodiment 3

[0072] Example 3: Self-heating low-temperature cartridge of the present invention

[0073] The implementation mode of this embodiment is as follows:

[0074] The self-heating low-temperature pod is composed of a smoke-generating section, a cooling section and a filter section connected in sequence; the smoking section is composed of a self-heating material, a smoking Mixed; of which:

[0075] The self-heating material is iron sold by Guangzhou Hongwu Material Technology Co., Ltd. under the trade name Nano-iron, and its particle size is a nano-metal material of 5nm; the self-heating material has a distribution density of 0.15g / cm 3 Uniformly distributed in the smoking flavor producing material, its content is 0.01% by weight of the smoking flavor producing material.

[0076] The smoke-flavoring material is a mixture of burley tobacco and flue-cured tobacco raw materials, rose fragrance flavors and fragrances sold under the trade name of Yunnan Bagu Biotechnology Co., Ltd., an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com