Multi-stage crushing system for cement production

A crushing system, cement technology, applied in mixers with rotating stirring devices, dissolving, grain processing, etc., can solve the problems of insufficient cement quality, poor crushing effect, and affecting the progress and efficiency of construction, so as to ensure The effect of production quality, ensuring construction efficiency and progress, and improving progress and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

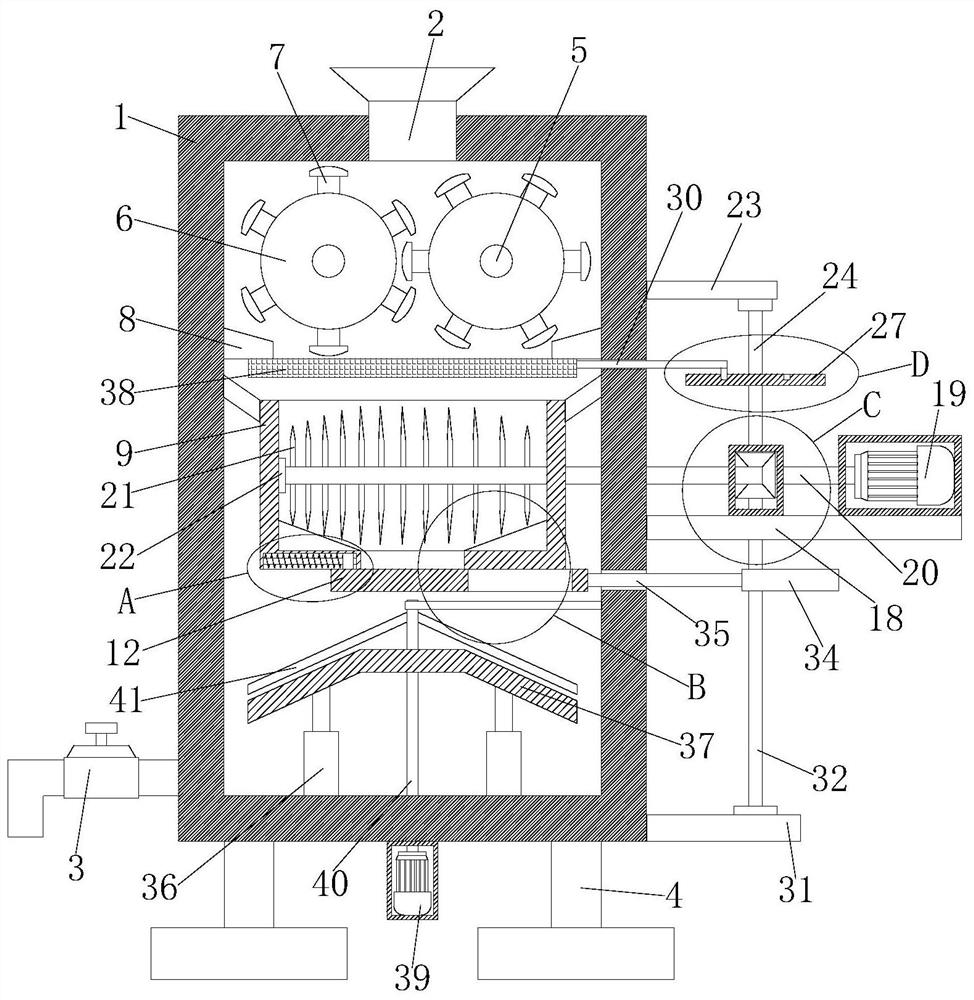

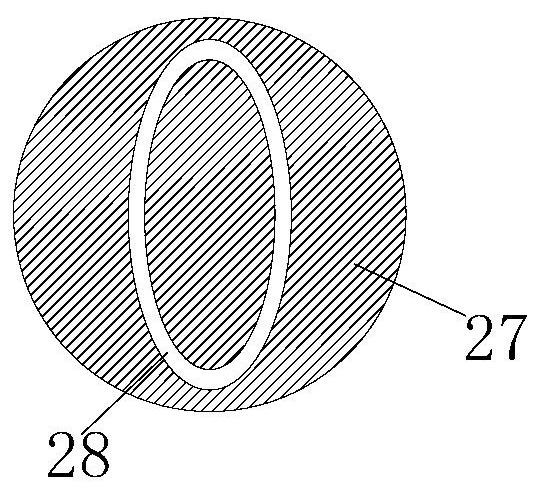

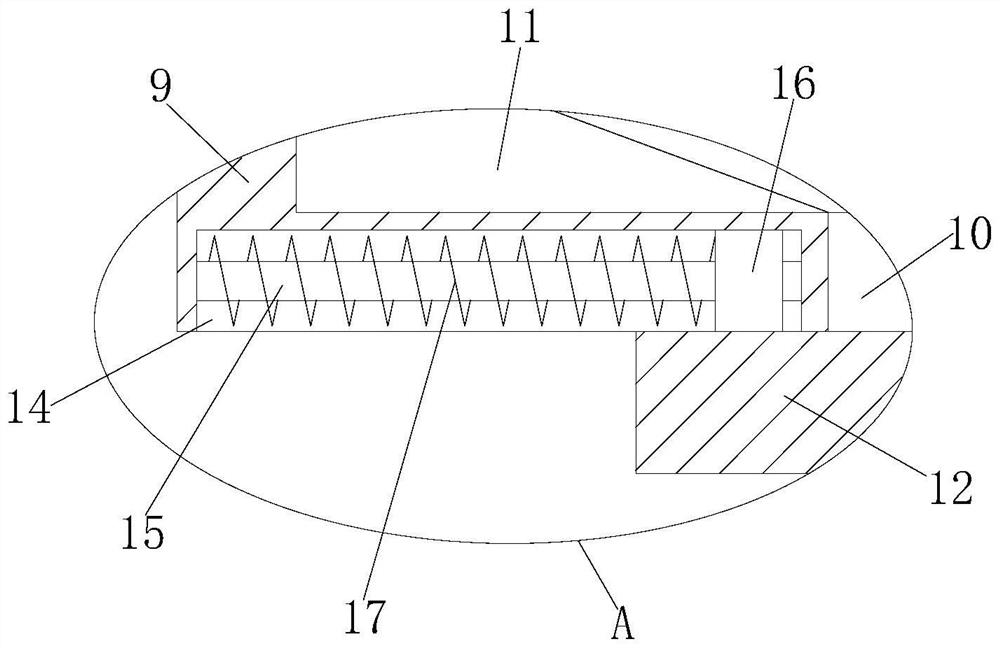

[0029] refer to Figure 1-6 , a multi-stage crushing system for cement production, including a box body 1, the top of the box body 1 is provided with a material inlet 2, the bottom of the box body 1 is symmetrically fixed with two brackets 4, and one side of the box body 1 A discharge port 3 is provided, and two rotating rods 5 are installed symmetrically in the box body 1, and a rotating disc 6 is fixedly installed on the two rotating rods 5, and several grinding rods 7 are fixedly installed on the two rotating discs 6, and several The two grinding rods 7 are suitable for preliminary grinding and crushing of the cement. The first inclined plates 8 are fixedly installed on the inner walls of both sides of the box body 1, and the bottom of the two first inclined plates 8 is slidingly installed with the same filter. Plate 38, a processing box 9 is fixedly installed in the box body 1, and two second inclined plates 11 are symmetrically fixedly installed in the processing box 9. T...

Embodiment 2

[0040] refer to Figure 1-6 , a multi-stage crushing system for cement production, including a box body 1, the top of the box body 1 is provided with a material inlet 2, the bottom of the box body 1 is symmetrically fixed with two brackets 4 by welding, and the bottom of the box body 1 There is a discharge port 3 on one side, and two rotating rods 5 are installed symmetrically in the box body 1, and a turntable 6 is fixedly installed on the two rotating rods 5 by welding, and a number of rotating discs 6 are fixed on the two turntables 6 by welding. A grinding rod 7, a plurality of grinding rods 7 are matched, can carry out preliminary grinding and crushing to cement, on the inner wall of both sides of box body 1, all are fixedly installed with first slanting plate 8 by welding, two first slanting plates 8 The same filter plate 38 is slidably installed at the bottom of the box body 1, and a treatment box 9 is fixedly installed by welding in the box body 1. Two second inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com