Automatic polishing equipment for surface of building wood

A wood surface, automatic polishing technology, applied in the field of wood processing, can solve the problems of inconvenient cooling of the wood surface, inconvenient cleaning of sawdust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

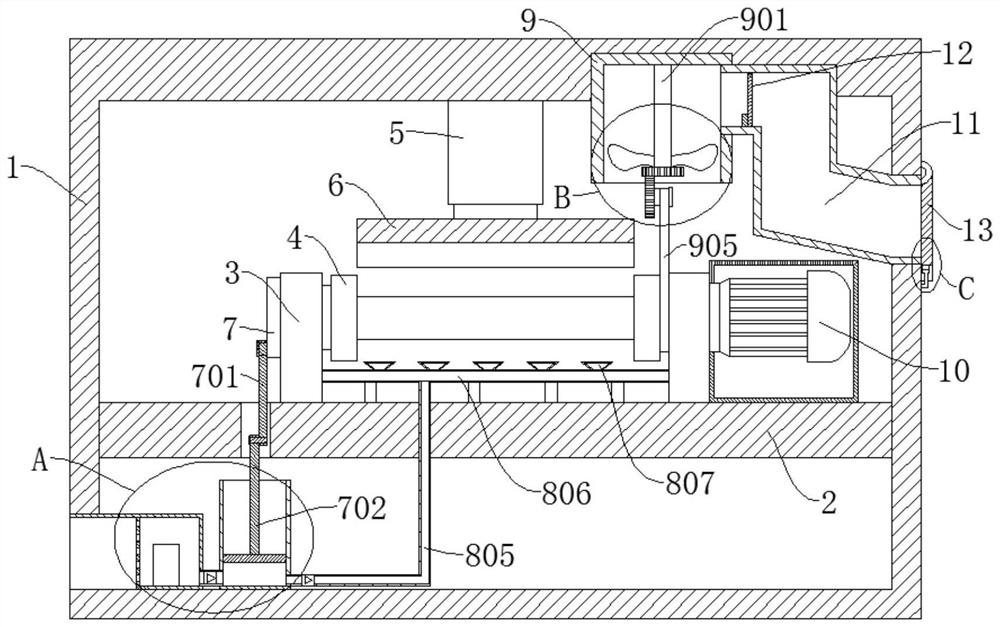

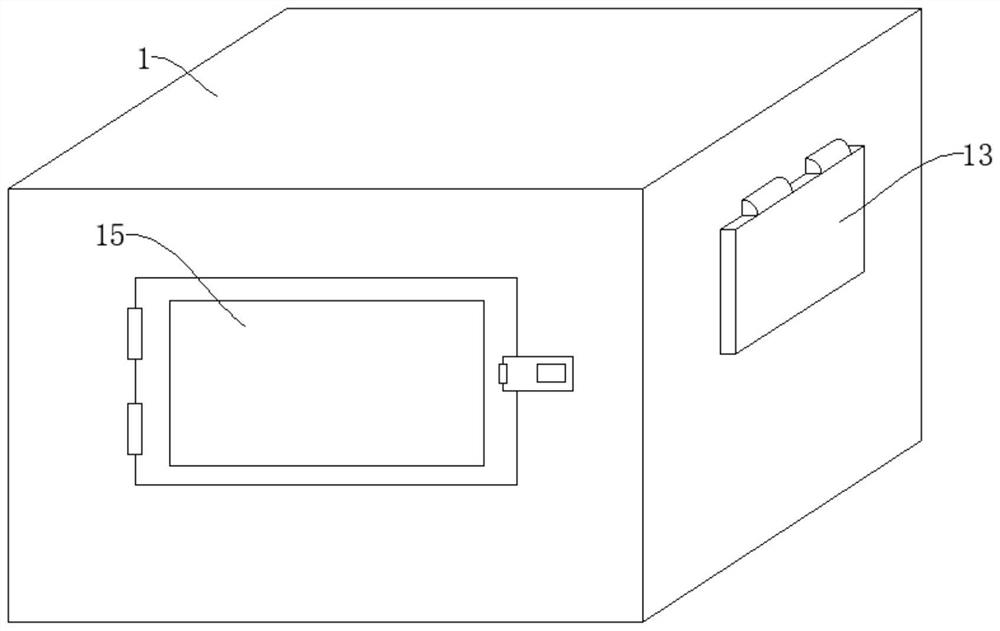

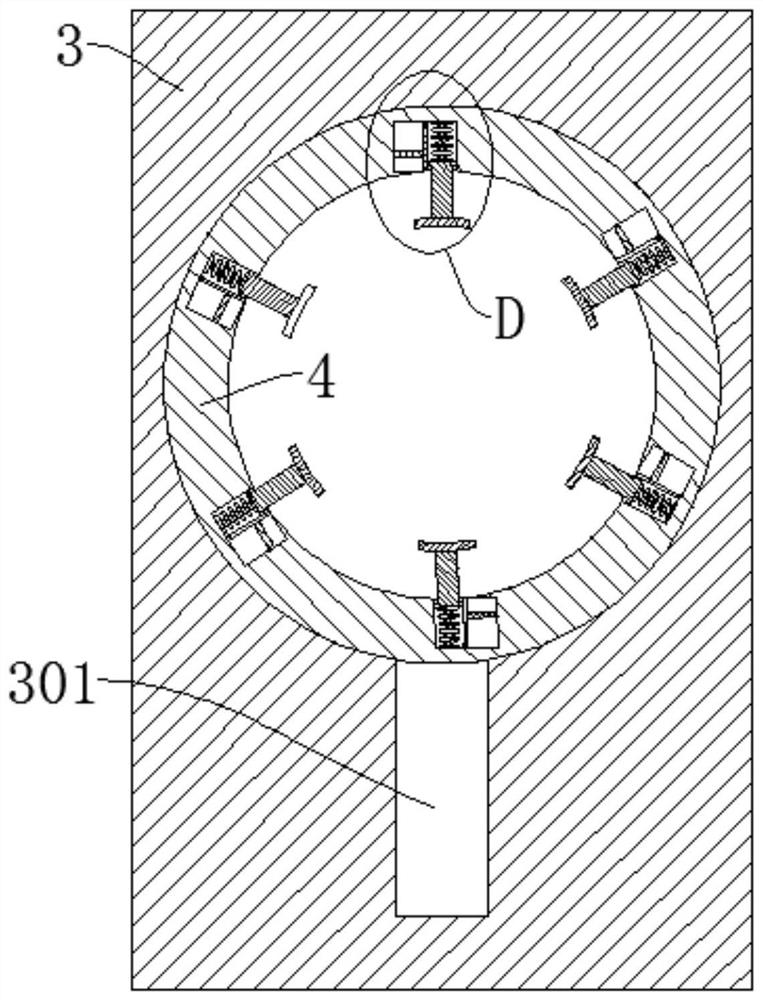

[0039] refer to Figure 1-7, an automatic polishing device for building wood surfaces, comprising a box body 1, a box door 15, the box door 15 is connected to the side wall of the box body 1 through hinges, the box body 1 is fixedly connected with a mounting plate 2, and the box body 1 The upper end of the interior is fixedly connected with an electric telescopic rod 5, the telescopic end of the electric telescopic rod 5 is fixedly connected with a polishing machine 6, two sets of support frames 3 are symmetrically fixedly connected to the mounting plate 2, and the support frame 3 is rotatably connected with a fixed shaft 4. One of the fixed rotating shafts 4 is provided with a drive motor 10, and the other fixed rotating shaft 4 is fixedly connected with a crank 7. The fixed rotating shaft 4 is provided with multiple sets of first air chambers 401, and the first air chambers 401 are slidingly connected with piston rods. 402, the end of the piston rod 402 located in the first ...

Embodiment 2

[0042] refer to Figure 1-7 , a kind of automatic polishing equipment for the surface of wood used in construction, which is basically the same as that in Embodiment 1, furthermore, a second gas bin 404 is arranged next to each first gas bin 401, and the first gas bin 401 is connected to the second gas bin 401. The bin 404 is connected by a conduit, and the second air bin 404 is slidably connected with a slider 405. The slider 405 is closely attached to the second air bin 404 and slides freely. When the fixed shaft 4 is rotating, the slider 405 is under the action of centrifugal force. Slide in the second air chamber 404, press the air in the second air chamber 404 into the first air chamber 401 through the conduit, and then push the piston rod 402 to further push the clamping block 406, so that the clamping block 406 and the polished The wood tightens further.

Embodiment 3

[0044] refer to Figure 1-7 , a kind of automatic polishing equipment for building wood surfaces, which is basically the same as that of Embodiment 1, furthermore, the air injection pipe 806 is located between the two fixed rotating shafts 4, and the nozzle 807 faces the area between the two fixed rotating shafts 4, which is convenient For cooling wood during polishing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com