Injection mold capable of leaving no parting lines on outer grooves of automobile door interior trim products

A technology for injection molds and car doors, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low pass rate, high work intensity, poor consistency, etc., to ensure quality consistency, improve demolding efficiency, The effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

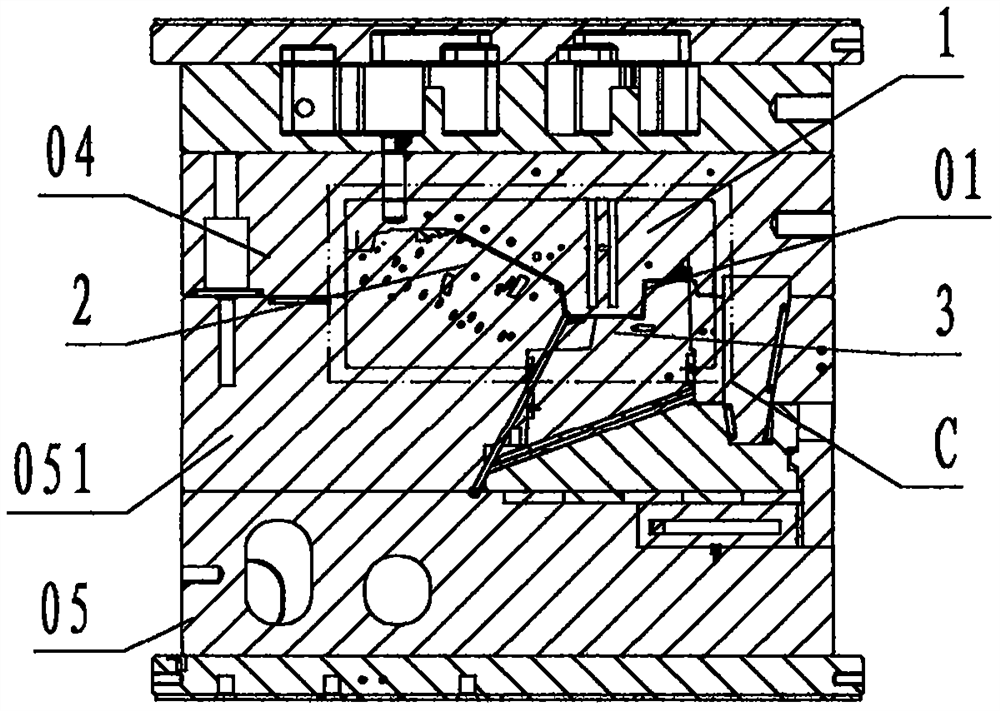

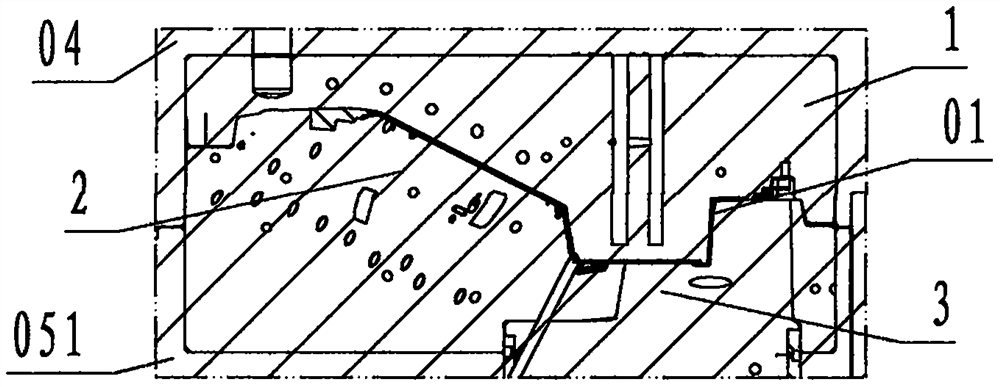

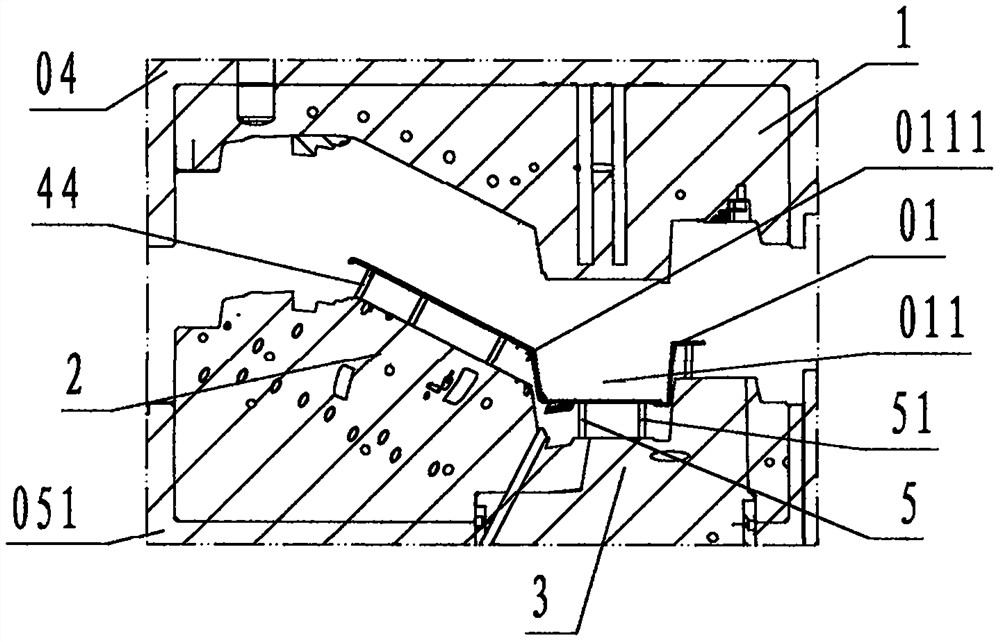

[0041]refer to Figure 1 to Figure 5 , an injection mold with no parting line in the outer groove of an automobile door interior trim product of the present invention, comprising a cavity 1, an A core 2, a B core 3, an inclined top mechanism 4 and a straight top mechanism 5, wherein: The cavity 1 described above is a rectangular block-shaped steel member. A model of the external shape of the molded product 01 is provided under the cavity 1. The cavity 1 is fixed under the fixed mold 04. The cavity 1 corresponds to the button on the right side of the product 01. The core-pulling and demoulding direction of the hand slot 011 is vertical;

[0042] The A-type core 2 is a block steel component, and the top of the A-type core 2 is provided with a molded product 01 back surface and a stud 012, a model of the ring buckle 013 structure;

[0043] The B-type core 3 is a block-shaped steel component, and the top of the B-type core 3 is provided with the model of the back surface of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com