A carbon fiber prepreg tow swing rod type segmented small tension conveying method and device

A carbon fiber prepreg and conveying device technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., to achieve the effect of reliable buffer stroke and stable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

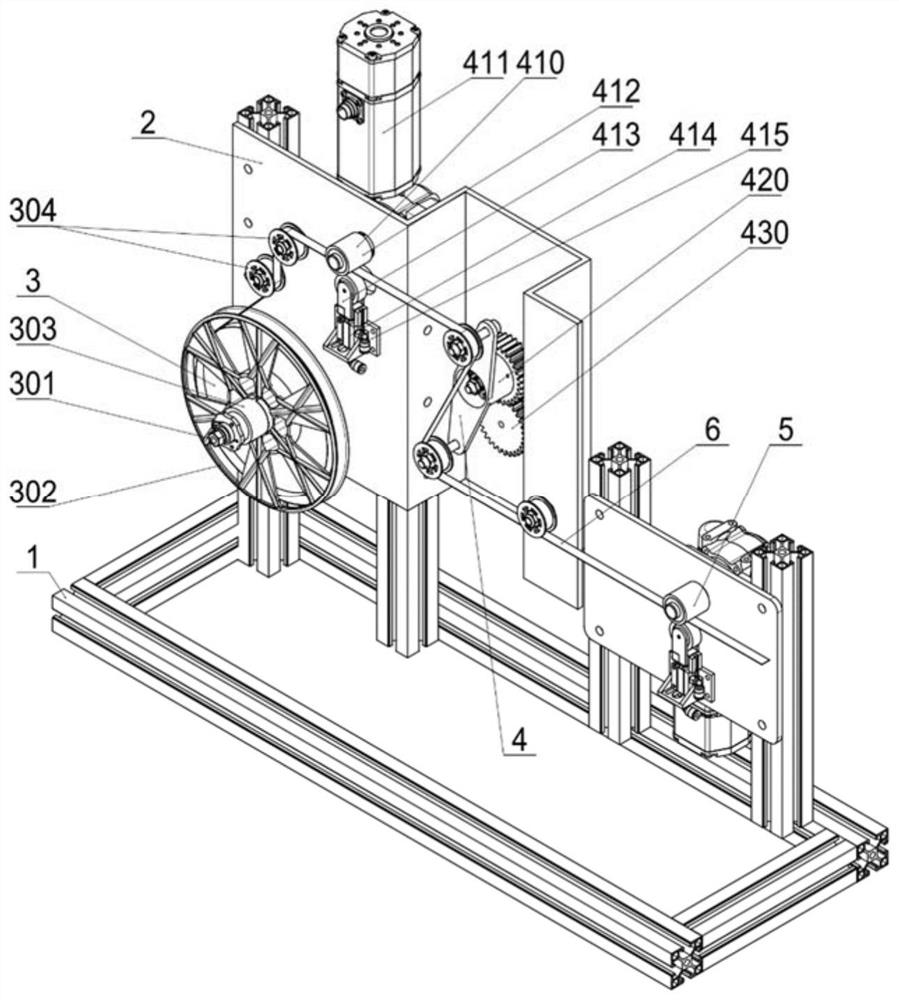

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

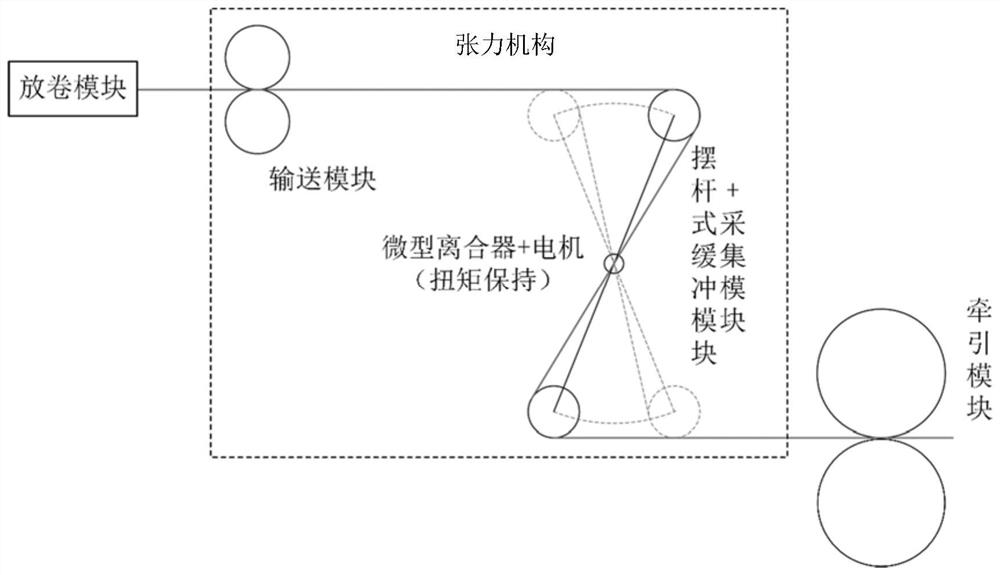

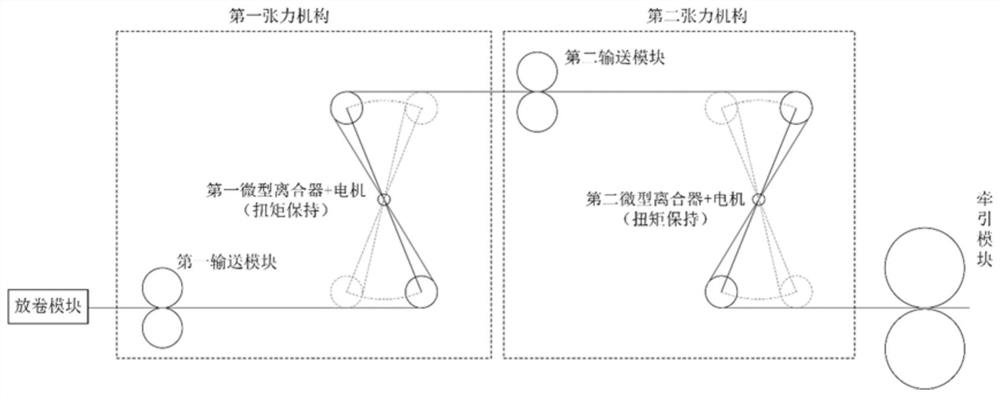

[0029] see figure 1 , a kind of prepreg tow pendulum type segmental small tension conveying method for automatic laying equipment of the present invention is as follows: in the laying process, the prepreg tow is sent out by the delivery module through the unwinding module, and enters Constant tension swing rod type buffer module, the prepreg tow tension is separated into two independent parts by the conveying module, the prepreg tow tension value before the conveying module is determined by the unwinding module, and the unwinding module is equipped with a brake or a clutch , adjusting the resistance of the brake or clutch can adjust the tension of this section. Generally, the tension value of this section is required to be higher. The tension value of the prepreg tow after the conveying module is determined by the swing rod buffer module. Generally, the tension value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com