A trolley line that can provide power supply for rotary rail change

A trolley line and rotating guide rail technology, applied in the field of trolley line, can solve problems such as the inability to meet the simultaneous operation of multiple cages, and achieve the effects of high work efficiency, improved conveying efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content, structural features, achieved objects and effects of the technical solution in detail, the following detailed description is given in conjunction with the specific embodiments and the accompanying drawings.

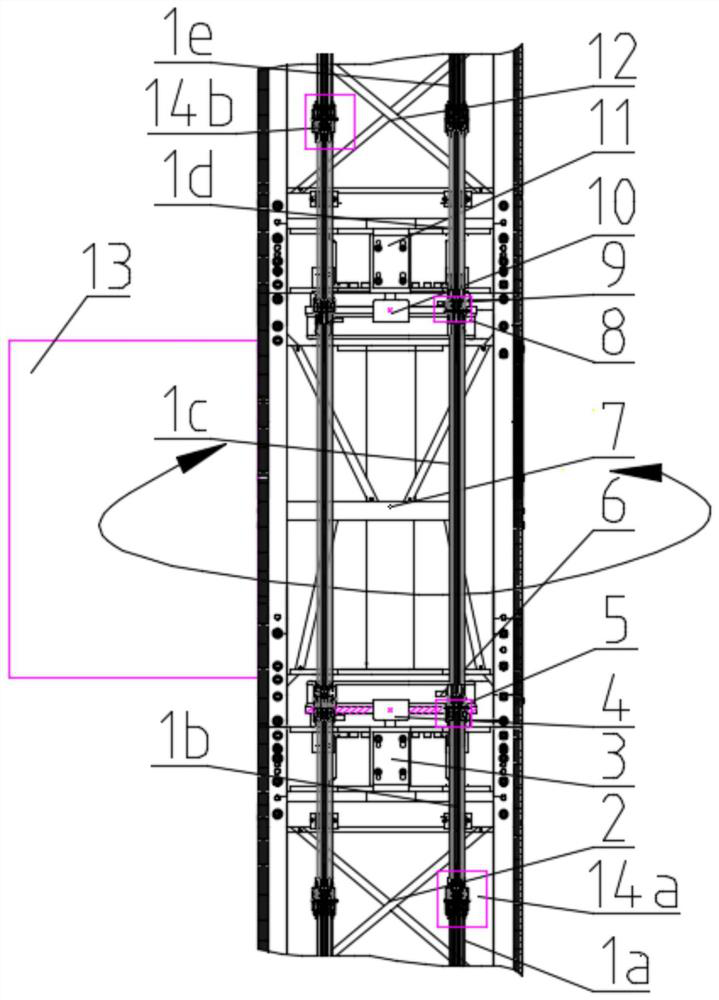

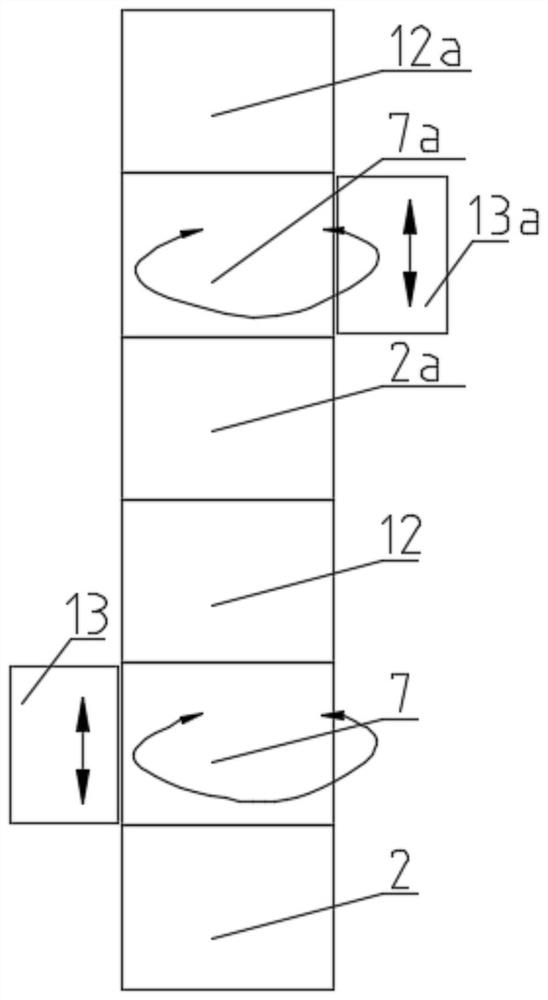

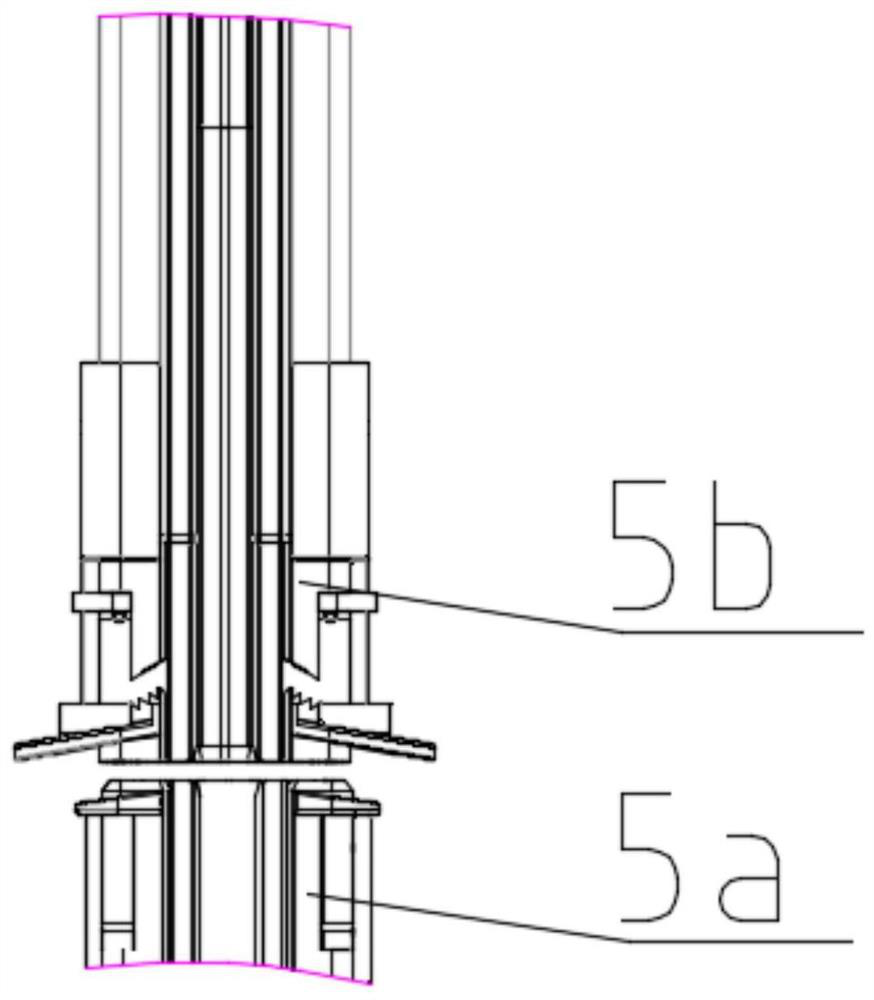

[0043] see figure 1 , this embodiment provides a trolley line that can provide power supply for rotating rails, the trolley line is multi-strand in use and is installed symmetrically at 180 degrees relative to the rotation center. Each trolley line is a multi-segment structure, and is specifically composed of a first power supply point trolley line 1a, a lower end trolley line 1b of the rotary joint, a lower fixed section 14a, a lower end trolley line roller 6, and a slewing joint power supply trolley line. 1c, the first lower transition rotary joint 5, the upper end sliding contact line 1d of the rotary joint, the upper end sliding contact line roller 9, the first upper transition rotary joint 8, the upper fixed joint 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com