A kind of polyurethane-based ionic liquid perfusion coating prefabricated liquid and its preparation method, ionic liquid perfusion coating

An ionic liquid, liquid infusion technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of expensive preparation of devices, unclean environmental protection, cumbersome steps, etc., and achieves broad market prospects, low prices, and simple operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The embodiment of the present application provides the first ionic liquid perfusion coating, the method comprising:

[0047] 1. Weigh 0.05g of thermoplastic polyurethane TPU and 0.5g of 1-butyl-3-methylimidazolium hexafluorophosphate [BMIM][PF 6 ] was added to a 5mL reagent bottle;

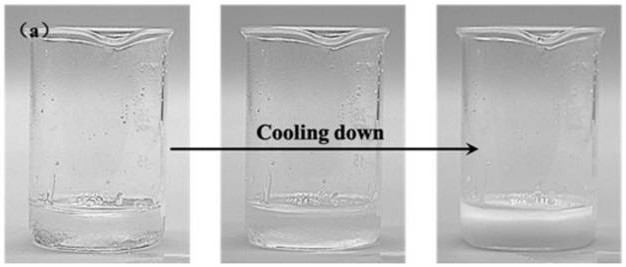

[0048] 2. Then, gradually heat in the oil bath, stir at a speed of 300rpm, heat to 180°C and keep the temperature for 3 hours to completely dissolve the polyurethane TPU in the ionic liquid [BMIM][PF 6 ] to form a homogeneous polyurethane-based ionic liquid perfusion coating prefabricated solution, place the polyurethane-based ionic liquid perfused coating prefabricated solution on a glass plate, and use a scraper to quickly scrape out a 1mm thick solution layer. After standing for 30s, the polyurethane-based ionic liquid perfusion coating prefabricated liquid cooled naturally and phase separation occurred to form the ionic liquid perfusion coating.

Embodiment 2

[0050] The embodiment of the present application provides a second ionic liquid perfusion coating, the method comprising:

[0051] 1. Weigh 0.2g of polyurethane TPU and 1g of 1-octyl-3-methylimidazolium hexafluorophosphate [OMIM][PF 6 ], added to the reagent bottle of 5mL;

[0052] 2. Then, gradually heat in the oil bath, stir at a speed of 300rpm, heat to 180°C and keep the temperature for 3 hours to completely dissolve the polyurethane TPU in the ionic liquid [OMIM][PF 6 ] The polyurethane-based ionic liquid perfusion coating prefabricated solution formed in ], put the polyurethane-based ionic liquid perfused coating prefabricated solution on a glass plate, and use a scraper to quickly scrape out a 1mm thick solution layer. After standing for 30s, the polyurethane-based ionic liquid perfusion coating prefabricated liquid cooled naturally and phase separation occurred to form the ionic liquid perfusion coating.

Embodiment 3

[0054] The embodiment of the present application provides a third ionic liquid perfusion coating, the method comprising:

[0055] 1. Weigh 0.2g of thermoplastic polyurethane TPU and 1g of 1-decyl-3-methylimidazolium hexafluorophosphate [DMIM][PF 6 ] was added to a 5mL reagent bottle;

[0056] 2. Then, gradually heat in the oil bath, stir at a speed of 300rpm, heat to 200°C and keep the temperature for 2 hours to completely dissolve the polyurethane TPU in the ionic liquid [DMIM][PF 6 ] to form a homogeneous polyurethane-based ionic liquid perfusion coating prefabricated solution, place the polyurethane-based ionic liquid perfused coating prefabricated solution on a glass plate, and use a scraper to quickly scrape out a 1mm thick solution layer. After standing for 30s, the polyurethane-based ionic liquid perfusion coating prefabricated liquid cooled naturally and phase separation occurred to form the ionic liquid perfusion coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com