A construction method of a superimposed wall system with cover and excavation upside down

A cover-excavation and construction method technology, which is applied to artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of easy water leakage, complicated construction technology, and difficult guarantee of construction quality, so as to save the construction period and increase the effective area , Improve construction efficiency and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

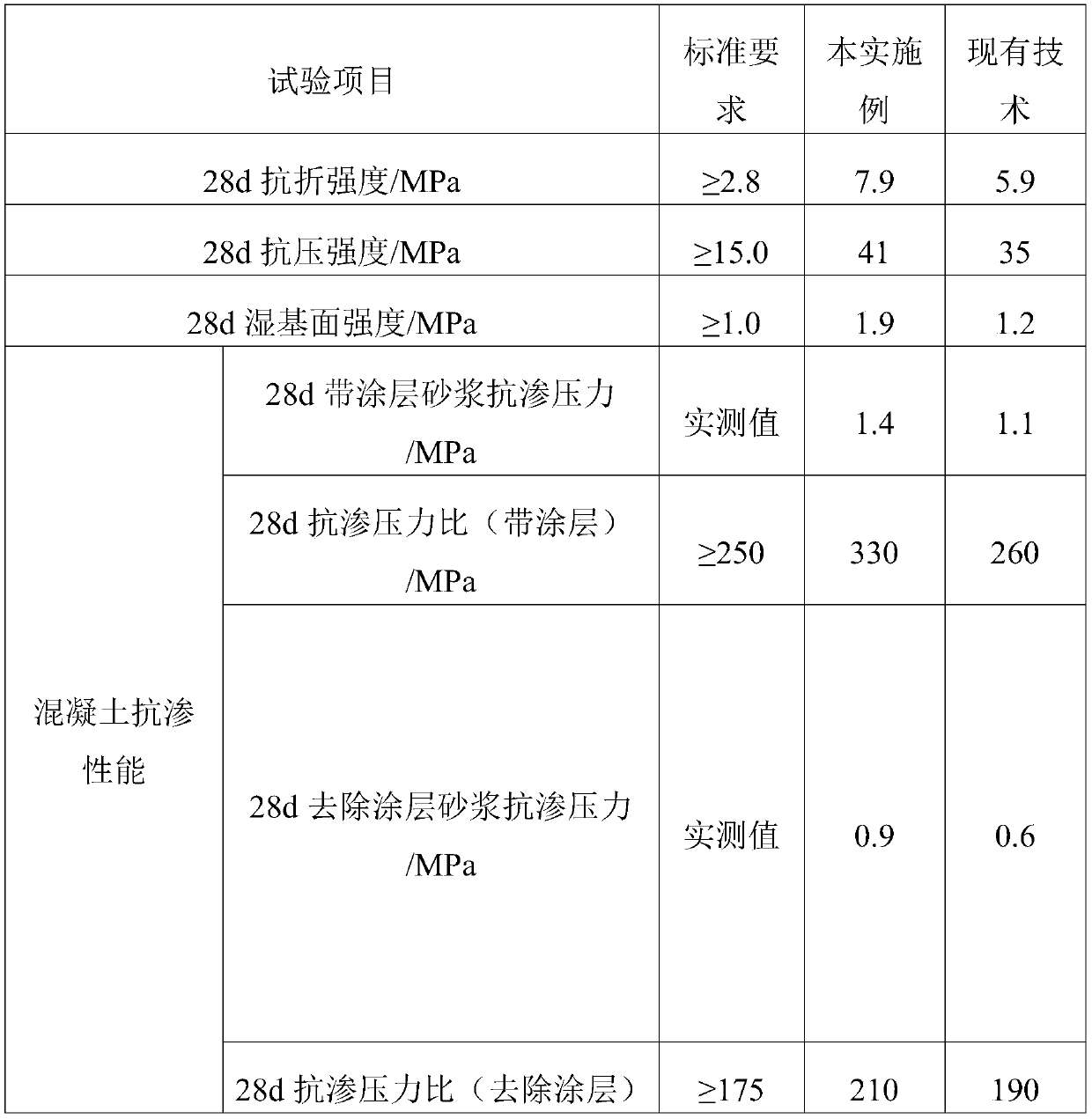

Embodiment 1

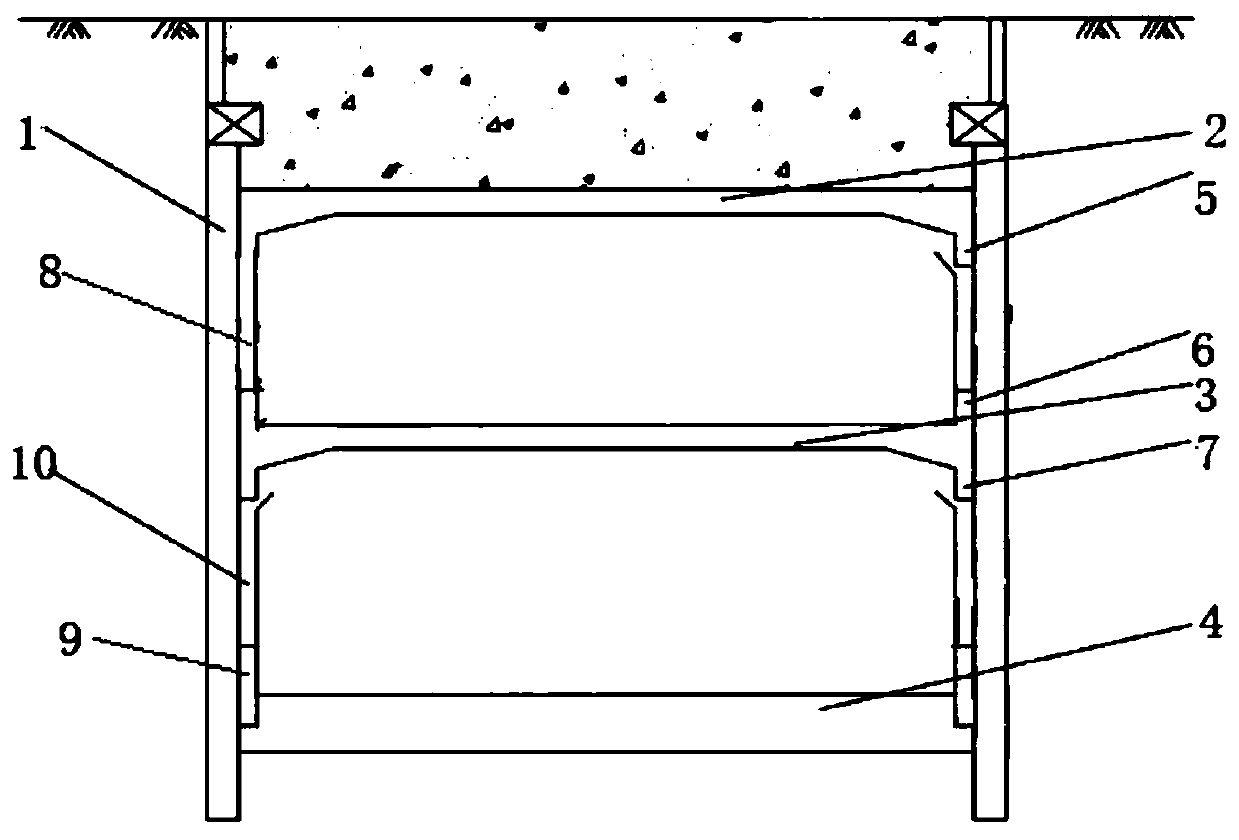

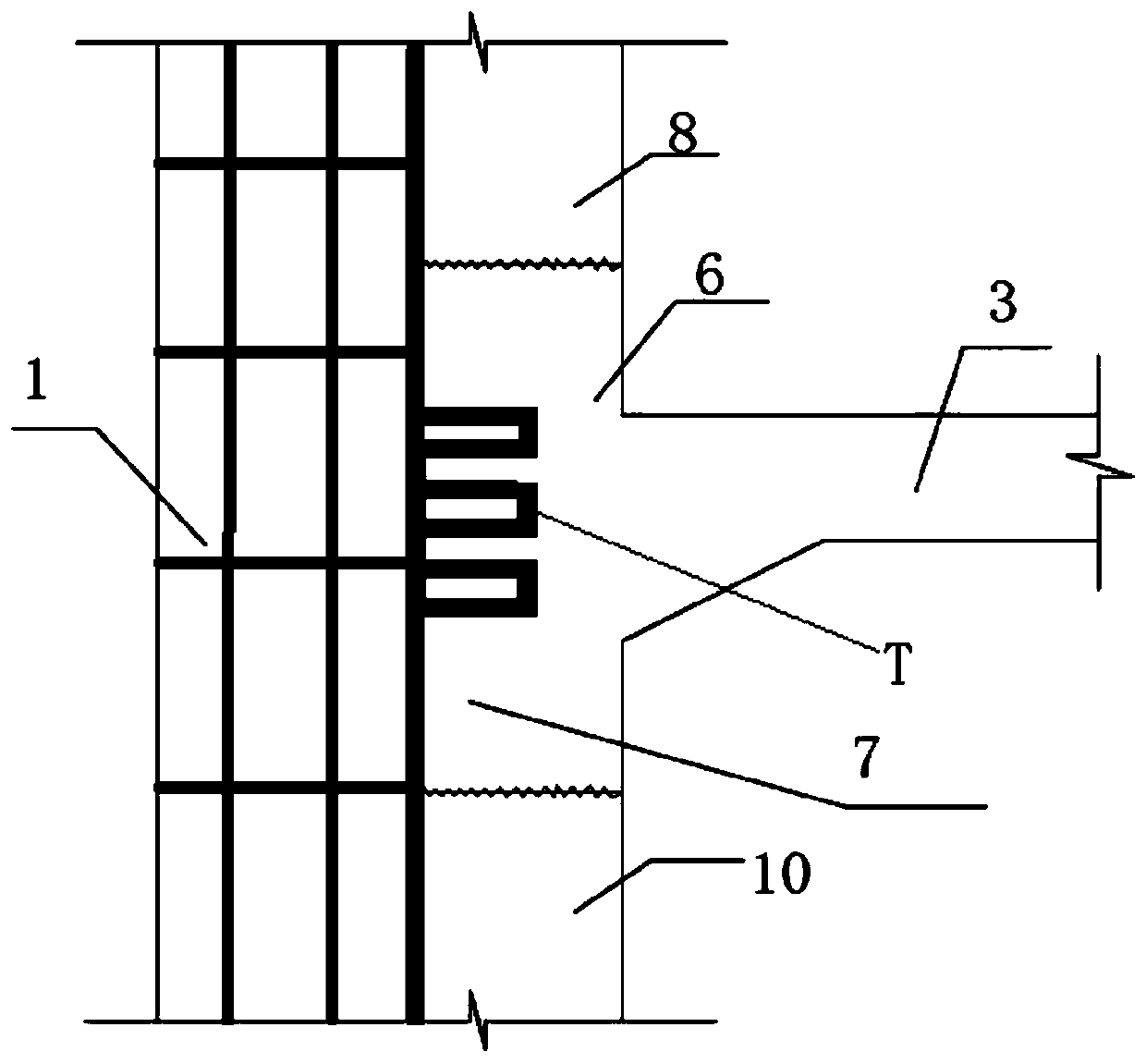

[0030] see Figure 1-2 , a construction method of a cover-excavation composite wall system comprising the following steps:

[0031] a. Construction of underground continuous maintenance wall 1: Set up and process the steel bars at the joints between the continuous wall and the roof, middle plate and bottom plate in the underground continuous maintenance wall 1, and reserve a plurality of steel bar joint structures T that protrude outward alternately. Forming an integral underground continuous maintenance wall reinforcement cage; temporarily covering the reinforcement joint structure T, pouring concrete after lowering the reinforcement cage to form an underground continuous maintenance wall 1 with a connection structure;

[0032] b. Construction of the roof 2 and the lower side wall 5 of the roof: Excavate the foundation pit of the roof and the groove of the lower side wall of the roof, chisel the surface of the concrete near the joint structure T of the continuous wall and the...

Embodiment 2

[0044] see Figure 1-2 , a construction method of a cover-excavation composite wall system comprising the following steps:

[0045] a. Construction of underground continuous maintenance wall 1: Set up and process the steel bars at the joints between the continuous wall and the roof, middle plate and bottom plate in the underground continuous maintenance wall 1, and reserve a plurality of steel bar joint structures T that protrude outward alternately. Forming an integral underground continuous maintenance wall reinforcement cage; temporarily covering the reinforcement joint structure T, pouring concrete after lowering the reinforcement cage to form an underground continuous maintenance wall 1 with a connection structure;

[0046] b. Construction of the roof 2 and the lower side wall 5 of the roof: Excavate the foundation pit of the roof and the groove of the lower side wall of the roof, chisel the surface of the concrete near the joint structure T of the continuous wall and the...

Embodiment 3

[0065] see Figure 1-2 , a construction method of a cover-excavation composite wall system comprising the following steps:

[0066] a. Construction of underground continuous maintenance wall 1: Set up and process the steel bars at the joints between the continuous wall and the roof, middle plate and bottom plate in the underground continuous maintenance wall 1, and reserve a plurality of steel bar joint structures T that protrude outward alternately. Forming an integral underground continuous maintenance wall reinforcement cage; temporarily covering the reinforcement joint structure T, pouring concrete after lowering the reinforcement cage to form an underground continuous maintenance wall 1 with a connection structure;

[0067] b. Construction of the roof 2 and the lower side wall 5 of the roof: Excavate the foundation pit of the roof and the groove of the lower side wall of the roof, chisel the surface of the concrete near the joint structure T of the continuous wall and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com