Fermentation tank for producing liquorice fermented beverage

A technology for fermented beverages and fermentation tanks, which is applied in the field of fermentation tanks for the production of licorice fermented beverages, which can solve the problems of foam destruction and limited defoaming effect, and achieve the effects of reasonable structure, improved defoaming effect, and promotion of axial flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

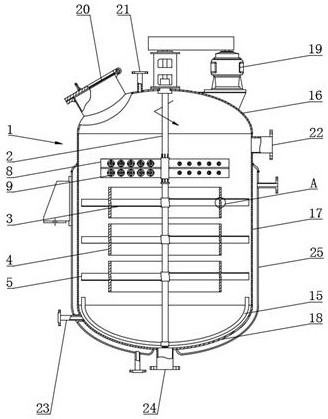

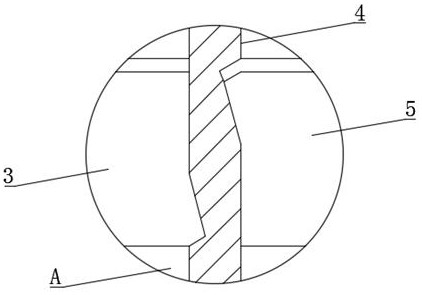

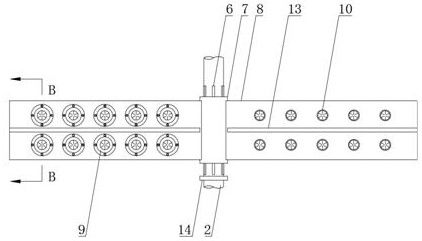

[0022] Example: see figure 1 with figure 2 , the present invention provides a fermenter for producing licorice fermented beverage, comprising a tank body 1, the tank body 1 is sequentially welded by an upper head 16, a cylinder body 17 and a lower head 18 from top to bottom. A deceleration motor 19 is installed on the upper head 16 through bolts, the output shaft of the deceleration motor 19 is connected to the stirring shaft 2 through a chain drive, a mechanical seal is installed between the stirring shaft 2 and the upper head 16, and a manhole is welded on the upper head 16 20 and air release pipe 21. A feed pipe 22 is welded on the barrel 17, and a sterile air inlet pipe 23 and a discharge pipe 24 are welded on the lower head 18. The sterile air inlet pipe 23 is used to exhaust the original atmosphere in the tank body 1 to avoid the original atmosphere. disrupt the fermentation process. A jacket 25 is welded to the outer periphery of the cylinder body 17 and the outer p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap