Organoid culture medium material and preparation method and application thereof

A technology for culturing substrate materials and organ culture, which is applied in the field of organoid culture substrate materials and its preparation, which can solve the problems of large batch-to-batch differences, complex components, and expensive prices, and achieve good dryness, simple preparation process, and dryness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

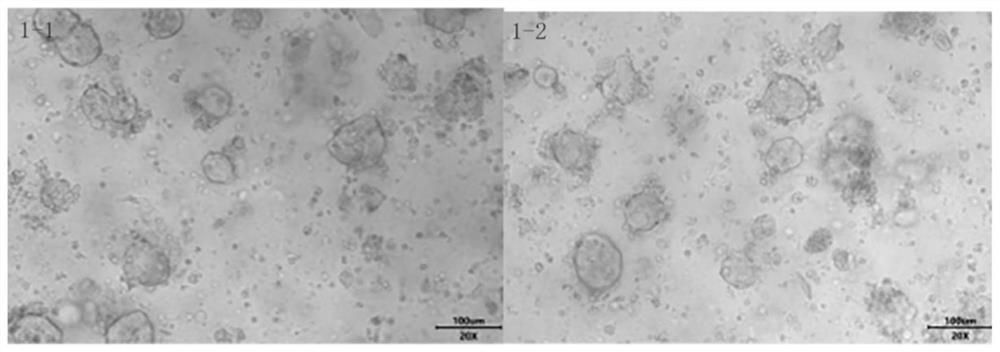

Embodiment 1

[0033] This embodiment provides a method for preparing an organoid culture matrix material, comprising the following steps:

[0034] (1) Dissolving collagen type 1, collagen type 4, laminin, hyaluronic acid, and heparin with 1% acetic acid solution to obtain a collagen solution, and storing it on an ice box;

[0035] (2) Add sodium dihydrogen phosphate, EGF, FGF, A83-01, and Y27632 into the high-sugar DMEM / reduced serum DMEM mixed nutrient solution, mix well, add cells to be cultured, and then mix well with the collagen solution , adjust the pH to 7.5 with 0.1M NaOH, wherein the volume ratio of high-sugar DMEM and reduced-serum DMEM in the high-sugar DMEM / reduced serum DMEM mixed nutrient solution is 5:1, and the final concentration of each component in the cell culture medium is: Type 1 collagen 12mg / ml, laminin 3.2mg / ml, type 4 collagen 0.1mg / ml, sodium dihydrogen phosphate 1%, hyaluronic acid 1mg / ml, heparin 0.9mg / ml, A83-01 0.9ng / ml, Y27632 15uM / ml, EGF 10ng / ml, FGF 100n...

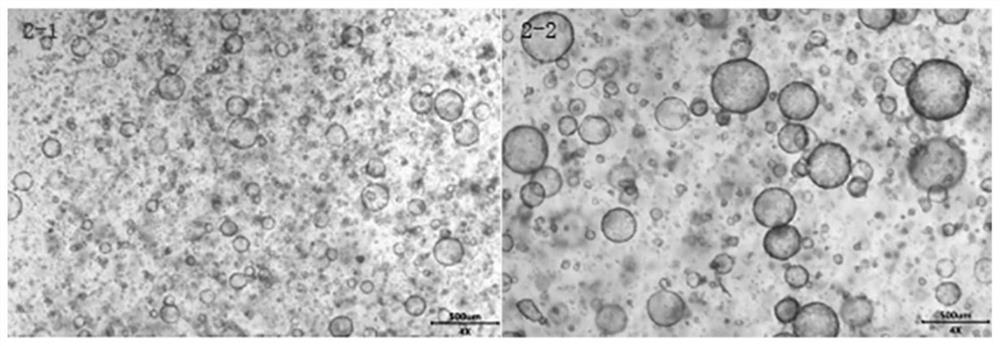

Embodiment 2

[0037] This embodiment provides a method for preparing an organoid culture matrix material, comprising the following steps:

[0038] (1) Dissolving collagen type 1, collagen type 4, laminin, hyaluronic acid, and heparin with 1% acetic acid solution to obtain a collagen solution, and storing it on an ice box;

[0039] (2) Add sodium dihydrogen phosphate, EGF, FGF, A83-01, and Y27632 into the high-sugar DMEM / serum-reduced DMEM mixed nutrient solution, mix well and then mix with the collagen solution, adjust the pH to 7.5 Obtained, wherein the volume ratio of high-sugar DMEM and reduced-serum DMEM in the mixed nutrient solution of high-sugar DMEM / reduced serum DMEM is 5:1, and the final concentration of each component in the cell culture medium is: collagen type 18 mg / ml, Laminin 1.5mg / ml, type IV collagen 1mg / ml, sodium dihydrogen phosphate 0.1%, hyaluronic acid 5mg / ml, heparin 0.5mg / ml, A83-01 1.9ng / ml, Y27632 8uM / ml, EGF 100ng / ml, FGF 10ng / ml.

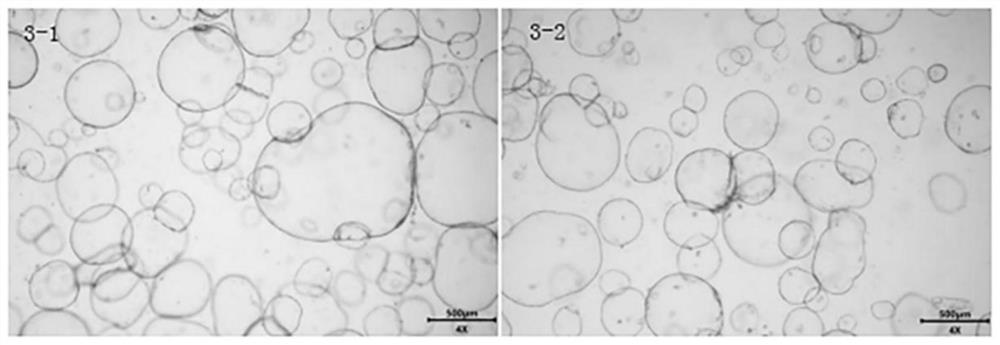

Embodiment 3

[0041] This embodiment provides a method for preparing an organoid culture matrix material, comprising the following steps:

[0042] (1) Dissolving collagen type 1, collagen type 4, laminin, hyaluronic acid, and heparin with 1% acetic acid solution to obtain a collagen solution, and storing it on an ice box;

[0043](2) Add sodium dihydrogen phosphate, EGF, FGF, A83-01, and Y27632 into the high-sugar DMEM / serum-reduced DMEM mixed nutrient solution, mix well and then mix well with the collagen solution, and adjust the pH to 7.5 Obtained, wherein the volume ratio of high-sugar DMEM and reduced-serum DMEM in the mixed nutrient solution of high-sugar DMEM / reduced serum DMEM is 5:1, and the final concentration of each component in the cell culture medium is: collagen type 15 mg / ml, Laminin 2mg / ml, type IV collagen 0.5mg / ml, sodium dihydrogen phosphate 0.5%, hyaluronic acid 3mg / ml, heparin 0.6mg / ml, A83-01 1.2ng / ml, Y27632 10uM / ml, EGF 50ng / ml, FGF 50ng / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com