A washing and drying integrated device and method for titanium sponge

A technology of washing and drying sponge titanium, which is applied in the direction of using liquid cleaning methods, drying, and drying solid materials, etc., can solve the problem that the sponge titanium magnesium chloride cannot be cleaned, the chlorine element in sponge titanium products exceeds the standard, and the quality grade of sponge titanium is affected and other problems, to achieve the effect of reducing the low washing efficiency, improving labor efficiency and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] All features disclosed in this specification, or all disclosed steps in a method or process, may be combined in any way except mutually exclusive features and / or steps.

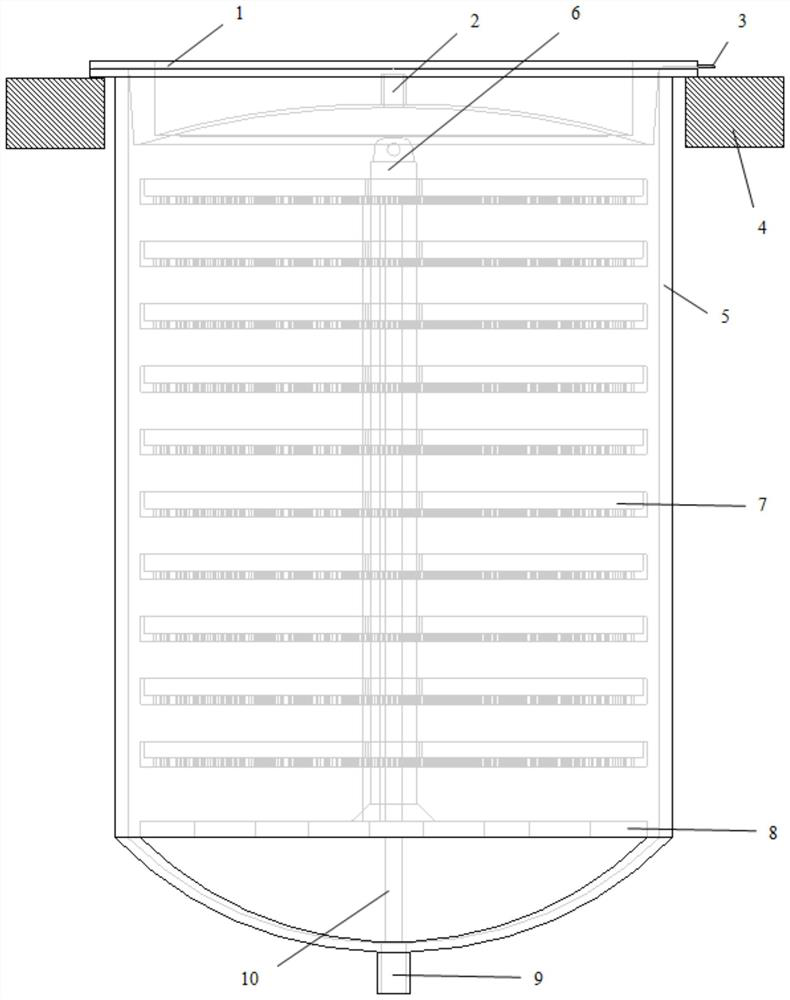

[0048] Combine below Figure 1 to Figure 3 The present invention will be described in detail.

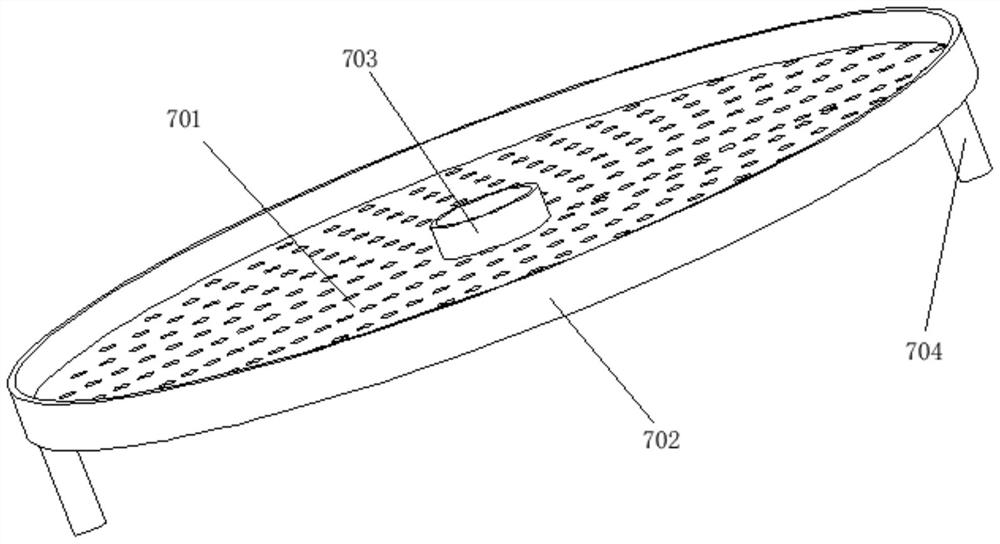

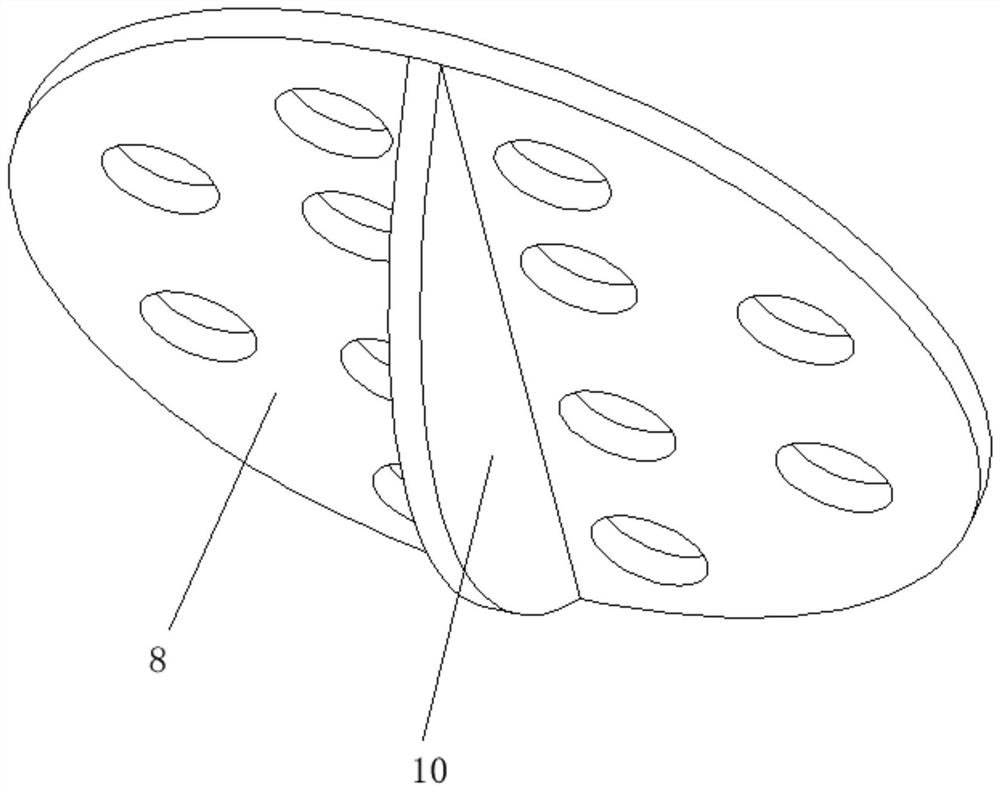

[0049] An integrated device for washing and drying sponge titanium, comprising a reactor 5, such as figure 1 As shown, the reactor 5 is arranged on the reactor operating platform 4, the top of the reactor 5 is provided with a rinsing water inlet 2, and the rinsing water inlet 2 is connected with a rinsing water system (not shown in the figure), The bottom of the reactor 5 is provided with a rinsing water outlet 9, the reactor 5 is provided with several layers of mesh frames 7 for holding sponge titanium, the reactor 5 is provided with a vacuum system interface 3, the vacuum system interface 3 A vacuum system (not shown in the figure) is connected. In this embodiment, the reactor 5 is a reactor that is defor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com