Composite yarn and preparation method thereof

A technology of yarn and blended yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of yarn mechanical strength, poor bending resistance, inability to meet strong antibacterial and bactericidal effects, and poor antibacterial and bactericidal effects, etc., to achieve deodorization Good ability, easy to dye evenly, and the effect of improving antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of composite yarn, comprising the following steps:

[0025] Step 1: the yarn core 8 is obtained through cleaning, carding, drawing, combing, drawing, roving, spun yarn, winding, doubling, and post-processing in sequence;

[0026] Step 2: the silver-plated fiber 3: the fiber substrate is chemically silver-plated or vacuum-plated with silver to form a silver-plated fiber;

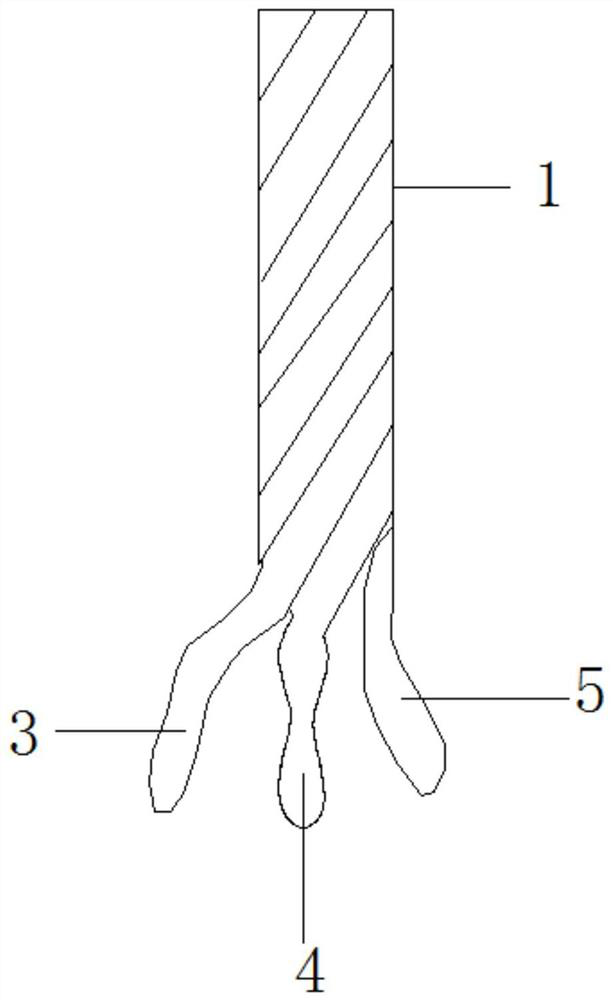

[0027] Step 3: Ply and blend silver-plated fiber 3, spun fiber 4, and bamboo charcoal fiber 5 to make blended yarn 1;

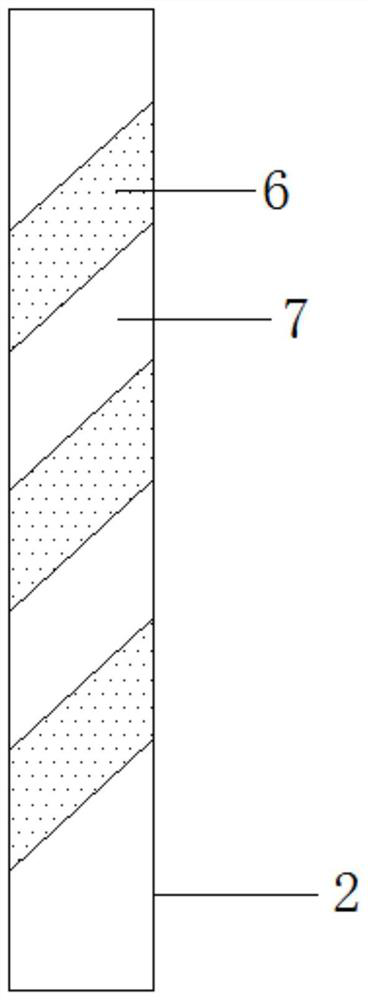

[0028] Step 4: The simulated silk polyester composite yarn 2: two types of fibers, the pre-oriented POY yarn 6 and the fully drawn FDY yarn 7, are networked to form a network yarn, and then twisted and heat-shrinked to shape;

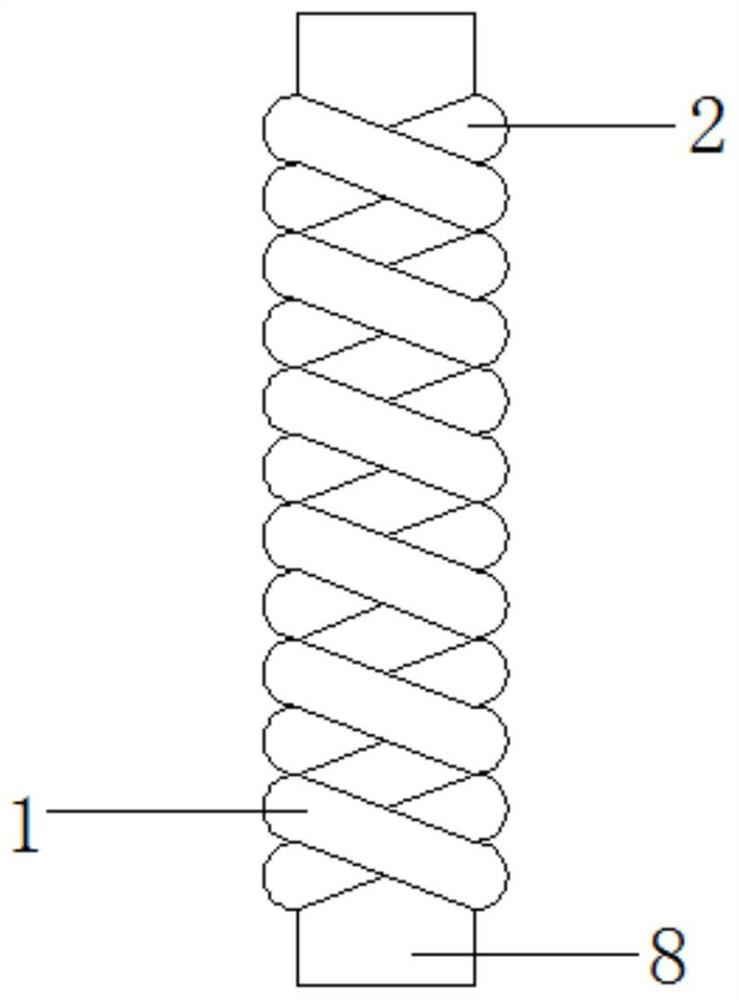

[0029] Step 5: Plying the blended yarn 1 with the imitation silk polyester composite yarn 2 and reversely twisting them on the yarn core 8 to form a composite yarn.

[0030] In order to further illustrate the preparation method, two speci...

Embodiment 1

[0031] Embodiment 1: the spun fiber 4 of the silver-plated fiber 3,89% and 10% bamboo charcoal fiber 5 of weight ratio 1% are mixed and loosened and made blended yarn 1 through compact siro spinning spinning process, blended Yarn 1 and imitation silk polyester composite yarn 2 are plied and reversely twisted to form a composite yarn on the yarn core 8, in which the silver-plated fiber 1 has good antibacterial performance and antibacterial rate, because the heat shrinkage rate of POY filament is obvious The ground is higher than the FDY yarn, the POY yarn shrinks, and the length becomes shorter, causing the FDY yarn to protrude and deform, and cover the surface of the composite fiber. The silk-like polyester composite yarn 2 has better elasticity, which improves the elasticity of the composite yarn and Tensile strength, bamboo charcoal fiber 5 has better deodorizing and sterilizing functions, and through the above processing, a composite yarn with stable structure, good luster, ...

Embodiment 2

[0032] Embodiment 2: after the silver-plated fiber of 3% by weight, the spinning fiber of 87% and the bamboo charcoal fiber of 10% are mixed and loosened, the blended yarn is made through the compact siro spinning process, and the blended yarn 1 and The imitation silk polyester composite yarn 2 is plied and reversely twisted to form a composite yarn on the yarn core 8, in which the silver-plated fiber 1 has better antibacterial performance and antibacterial rate, because the heat shrinkage rate of POY silk is significantly higher than that of FDY Filament, POY filament shrinks, the length becomes shorter, causing FDY filament to protrude and deform, and cover the surface of the composite fiber. The simulated silk polyester composite yarn 2 has better elasticity, which improves the elasticity and tensile capacity of the composite yarn. Bamboo charcoal fiber 5 has better deodorizing and sterilizing functions, and through the above-mentioned processing, a composite yarn with stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com