Bottom shell component, shell structure and heat exchange equipment applying bottom shell component and shell structure

A technology of heat exchange equipment and shell structure, which is applied to lighting and heating equipment, fluid heaters, sound-producing equipment, etc., can solve the problem of poor noise reduction effect of bottom shell structure, high noise of heat exchange equipment, affecting the physical and mental health of users, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

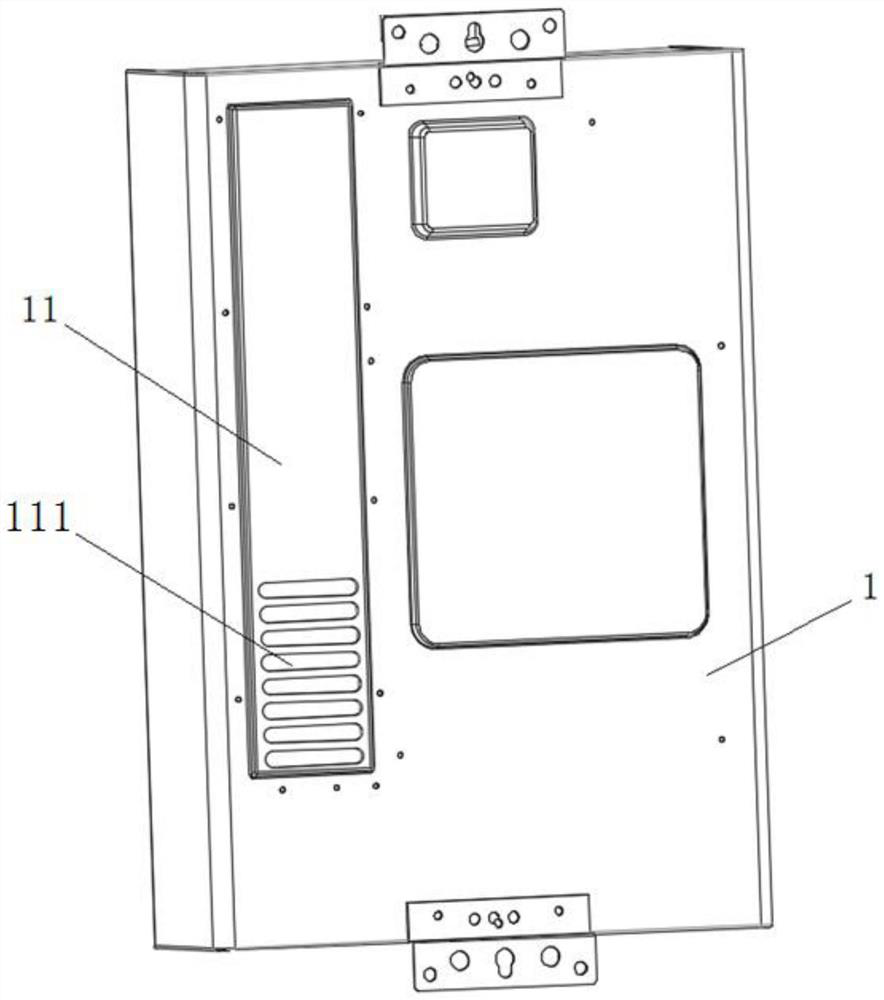

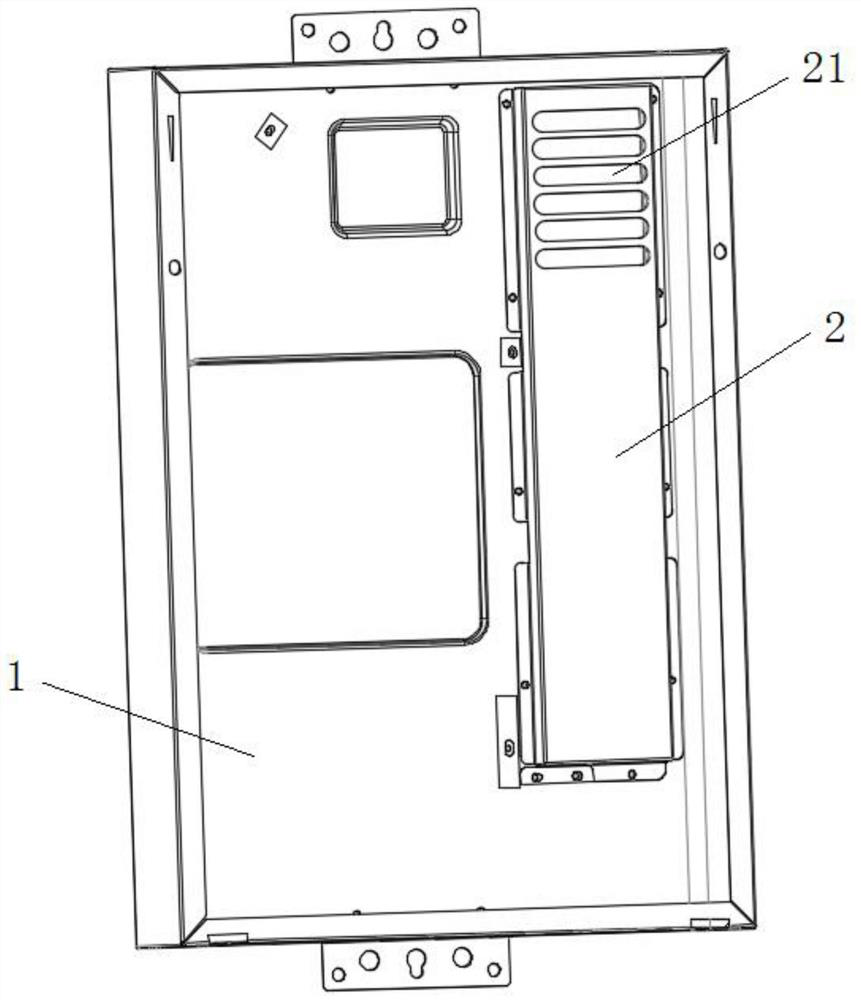

[0031] A bottom shell assembly provided by Embodiment 1 of the present invention is used for heat exchange equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom case body 1 and a silent cover plate 2. The bottom case body 1 is provided with a bottom case pressing recess 11, and the silent cover plate 2 is arranged on the bottom case body 1 to correspond to the bottom case pressing recess 11. The silent air channel is formed at the position to reduce the noise generated by the heat exchange equipment.

[0032] After adopting the above scheme, by setting the bottom case molding recess 11 on the bottom case body 1, and setting the silent cover plate 2 at the position corresponding to the bottom case molding recess 11 on the bottom case body, the two are connected to form Silent air channel, so that the noise generated when the heat exchange equipment is working first enters the silent air channel, and the silent air channel performs noise reduction...

Embodiment 2

[0047] A casing structure provided by Embodiment 2 of the present invention includes a face shell assembly, the bottom shell assembly described in Embodiment 1, and a sealing strip, and the face shell assembly and the bottom shell assembly are connected through the sealing strip.

[0048] By adopting the shell structure including the bottom shell assembly described in Embodiment 1, when the shell structure is applied to the heat exchange equipment, the noise generated by the heat exchange equipment can be effectively reduced, thereby avoiding Users have adverse reactions such as irritability, headache, and heart palpitations, which improves the comfort of users after use.

Embodiment 3

[0050] A kind of heat exchange equipment provided by Embodiment 3 of the present invention, such as Figure 7 As shown, the fan assembly 4 and the casing structure described in Embodiment 2 are included, and the fan assembly 4 is arranged in the casing structure and located at the air outlet in the casing structure.

[0051] The reason why the fan assembly 4 is arranged in the shell structure and at the air outlet 21 in the shell structure is: because when the heat exchange equipment is working, it needs to extract air from the outside, because the shell structure removes air and makes noise Except the connection between the channel and the outside, other parts are airtight, so that when the heat exchange equipment is working, the required air enters the air silent channel from the air inlet 111 on the bottom shell assembly, and then flows out from the air outlet 21 on the bottom shell assembly , to reach the inside, to meet the air volume required by the gas water heater, but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com