Refrigerator

A refrigerator and box body technology, applied in the field of refrigerators, can solve the problems of reducing the cooling capacity of the refrigerating evaporator, uneven temperature distribution in the refrigerating room, and the cooling capacity cannot be used by the compartment, so as to improve the space utilization rate and shorten the air supply distance. , The effect of preventing the wind from the fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

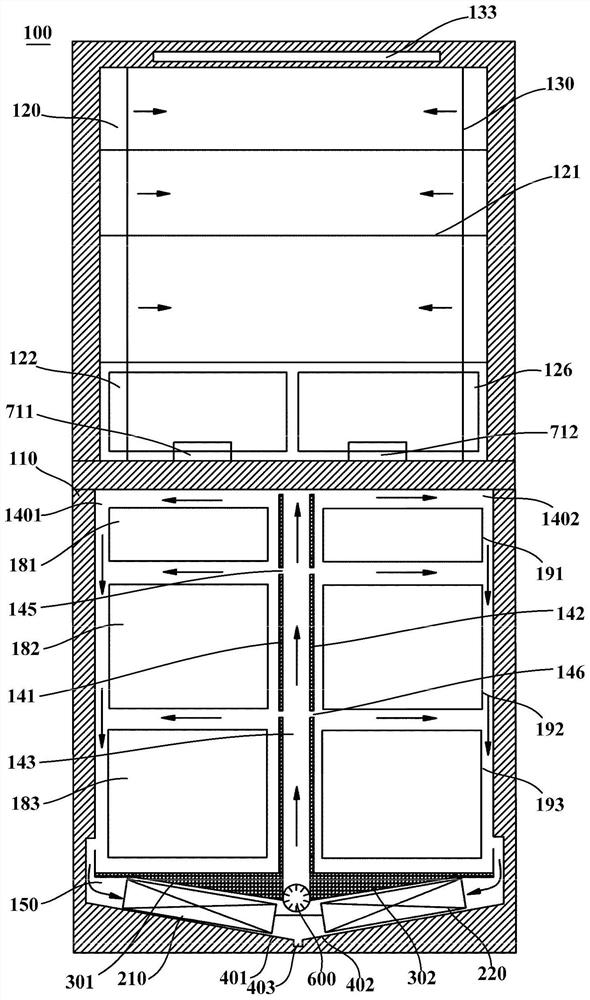

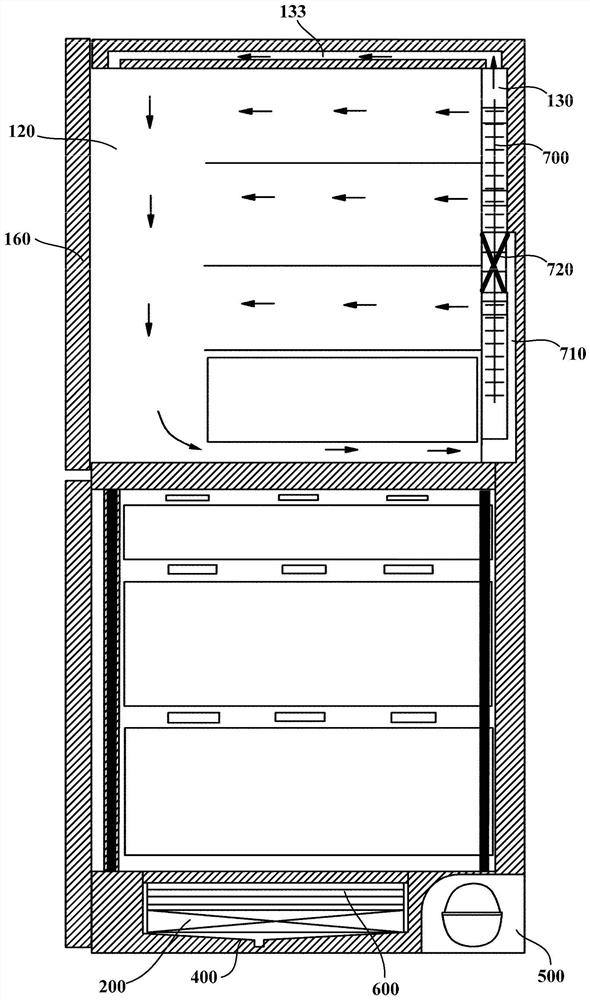

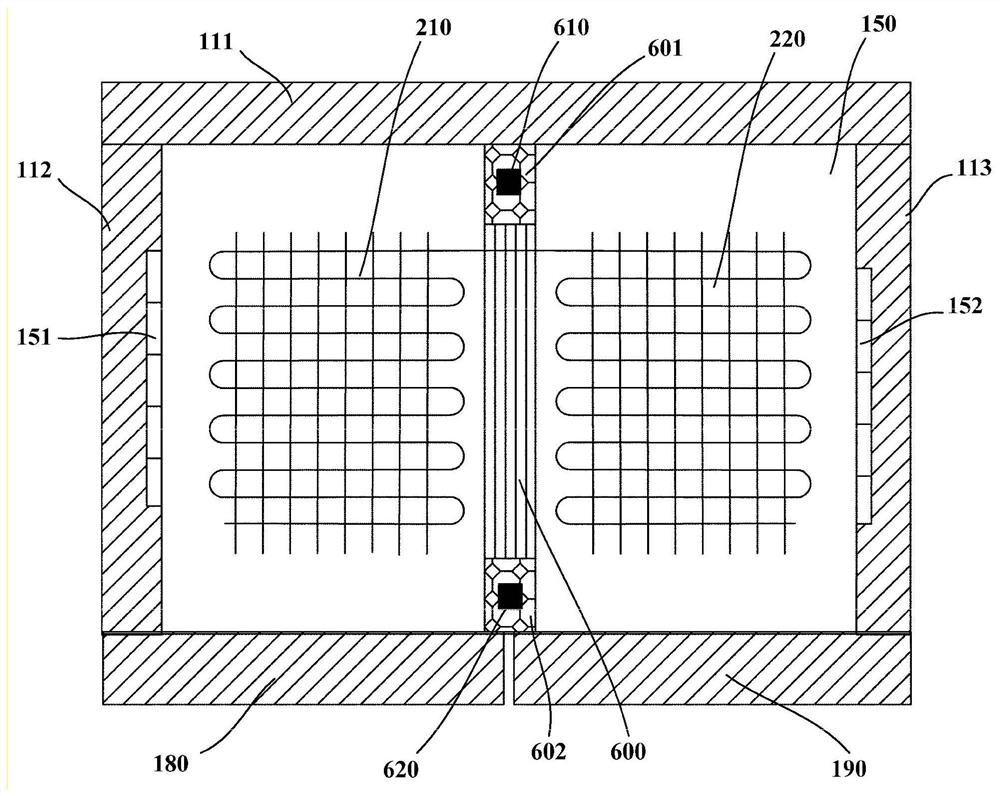

[0053] figure 1 is a front schematic sectional view of a refrigerator 100 according to an embodiment of the present invention. figure 2 is a side schematic sectional view of a refrigerator 100 according to an embodiment of the present invention. image 3 yes figure 1 A schematic top view of the first evaporator 200 of the refrigerator 100 is shown. In the following description, orientations or positional relationships indicated by "front", "rear", "upper", "lower", "left", "right", etc. are orientations based on the refrigerator 100 itself as a reference.

[0054] The refrigerator 100 of the embodiment of the present invention may generally include a box body 110. The box body 110 includes an outer shell and a storage liner arranged inside the outer shell. The space between the outer shell and the storage liner is filled with thermal insulation material (forming a Bubble layer), the storage liner is defined with a storage compartment. In one embodiment, the storage compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com