Dead-corner-free treatment device for non-woven fabric for mask production

A treatment device with no dead angle technology, applied in the direction of water supply device, dry gas arrangement, sanitary equipment for toilets, etc., can solve the problems that cannot be realized, the contact efficiency between cloth and disinfection liquid is not enough, and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

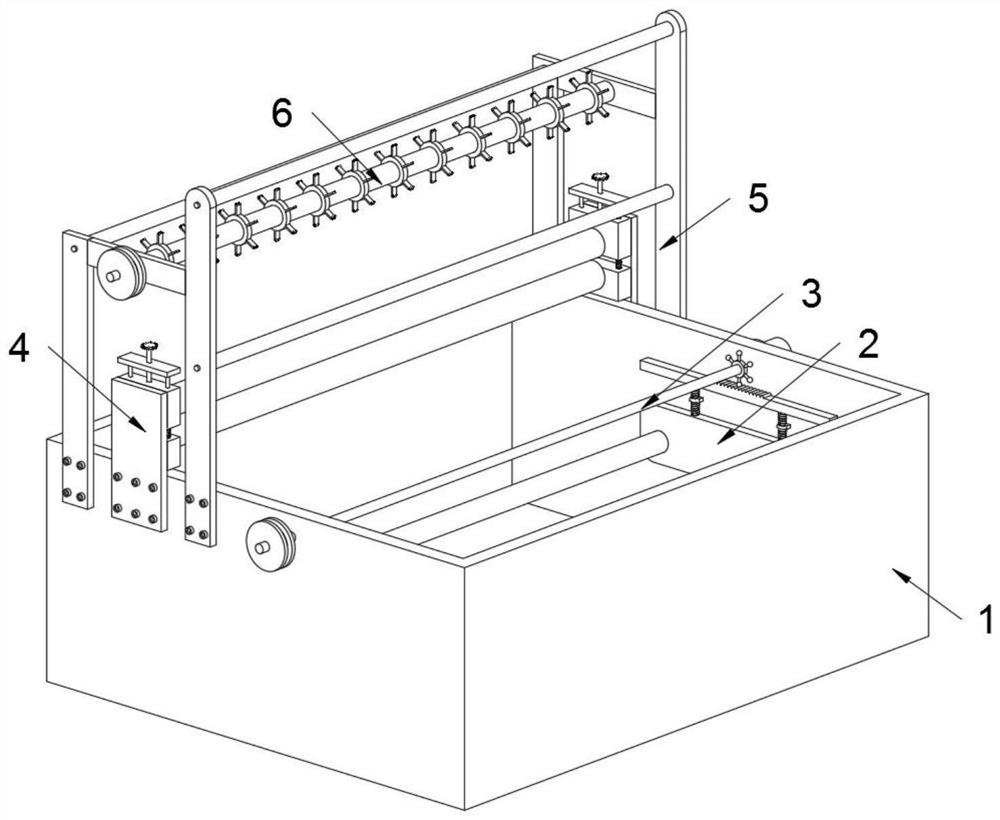

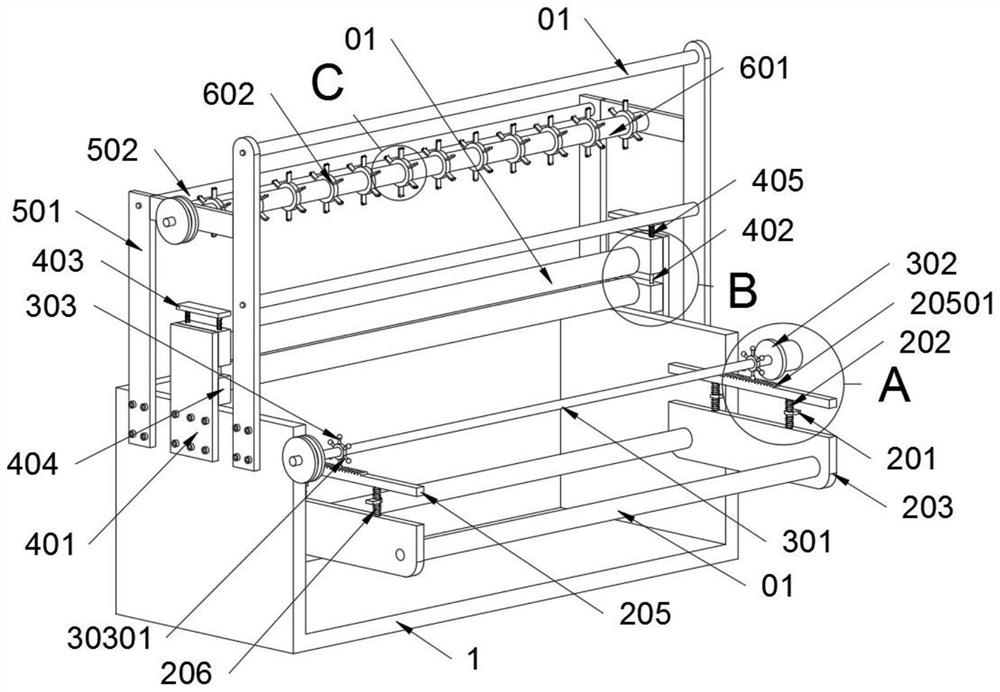

[0035] as attached figure 1 To attach Figure 8 Shown:

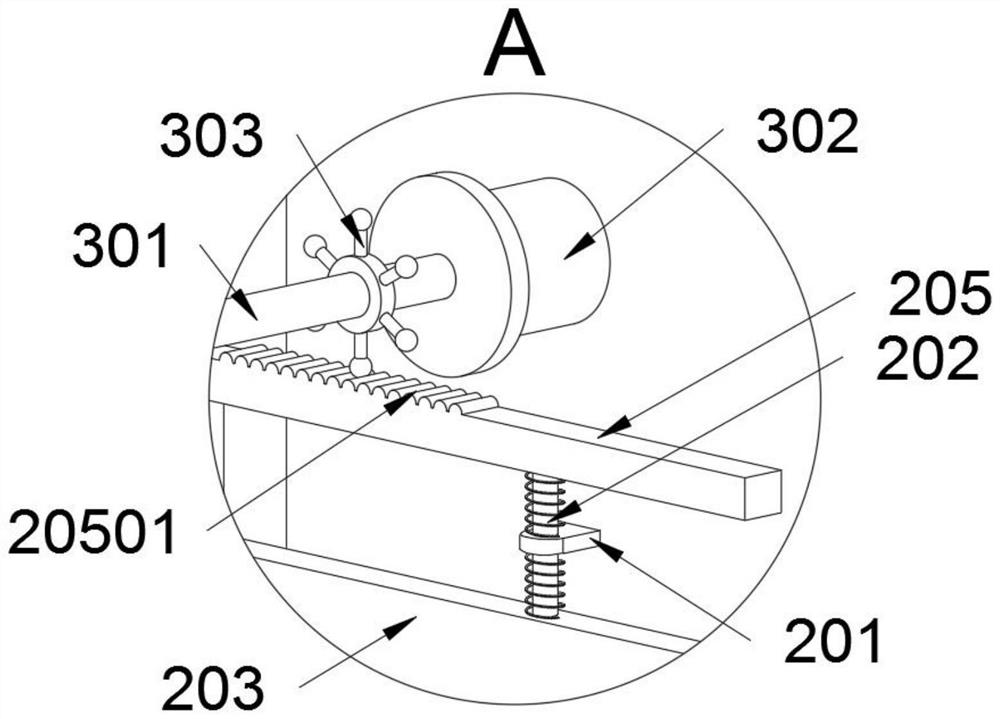

[0036] The invention provides a non-dead-angle processing device for non-woven fabrics for mask production, comprising a liquid storage tank 1; a support structure 2 is installed on the liquid storage tank 1, and a driving structure 3 is also installed on the liquid storage tank 1, and the storage tank 1 A water squeezing structure 4 is also installed on the liquid tank 1; a cloth guide frame 5 is installed on the liquid storage tank 1, and a drying structure 6 is installed on the cloth guide frame 5; refer to as Figure 8 , the drying structure 6 includes a nozzle 601, the nozzle 601 is a cylindrical tubular structure, and the nozzle 601 is rotatably connected to the cloth guide frame 5, and the nozzle 601 is connected with an air pump that provides high-heat air; the outer wall of the nozzle 601 is annular There are nozzle holes in an array, and the nozzle 601 is located in the middle of the V-shaped path of the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com