Method and system for simulating motion trail of solid inclusions in molten steel

A technology of motion trajectory and simulation method, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

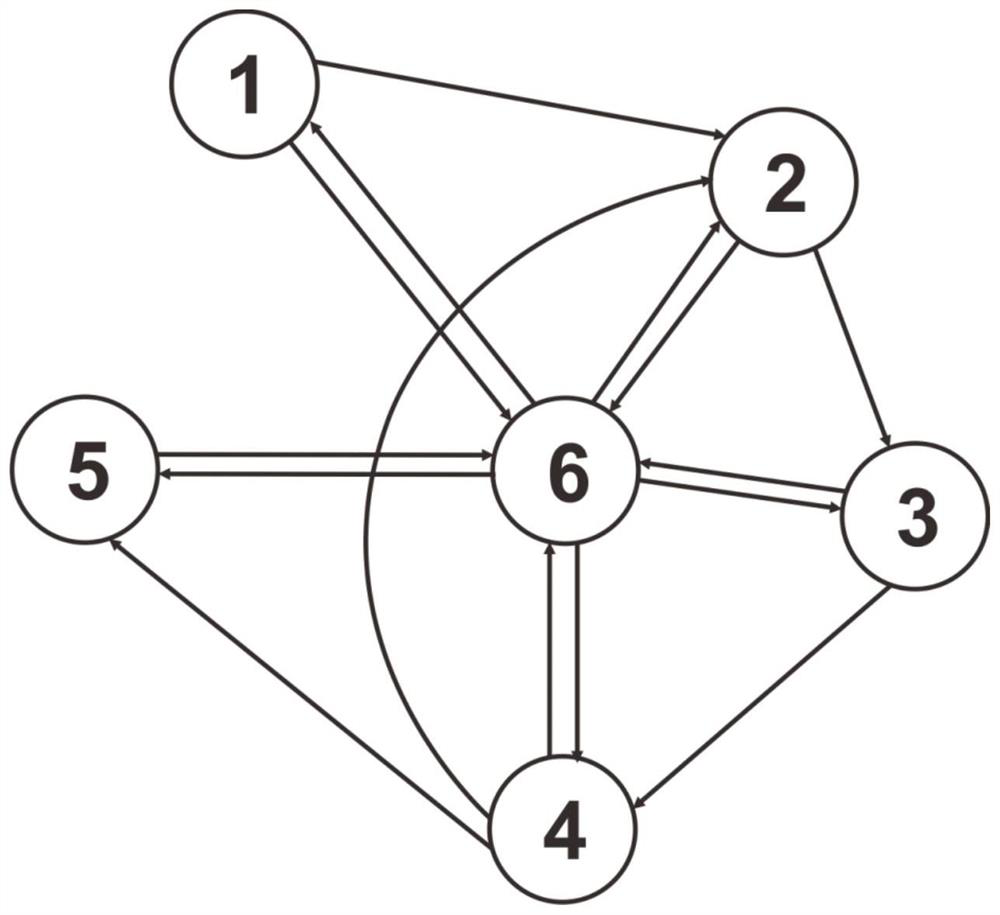

[0085] refer to figure 1 , in the present embodiment, propose a kind of simulation system that is used for solid inclusion moving track in molten steel, described system comprises:

[0086] The inclusion initial state data storage module is used to save the initial state data of the inclusions;

[0087] The flow field data calling module is used to extract the initial state data of the inclusions and calculate the flow field data of the inclusions;

[0088] inclusion force calculation module, used to extract the flow field data and calculate the inclusion force data;

[0089] The inclusion movement trajectory calculation module is used to extract the force data of the inclusions and calculate the spatial coordinate data of the inclusions;

[0090] The calculation result storage module is used to save the finally calculated spatial coordinates of inclusions; and

[0091] The control module is used to set the calculation step size, extract the spatial coordinates of the inclu...

Embodiment 2

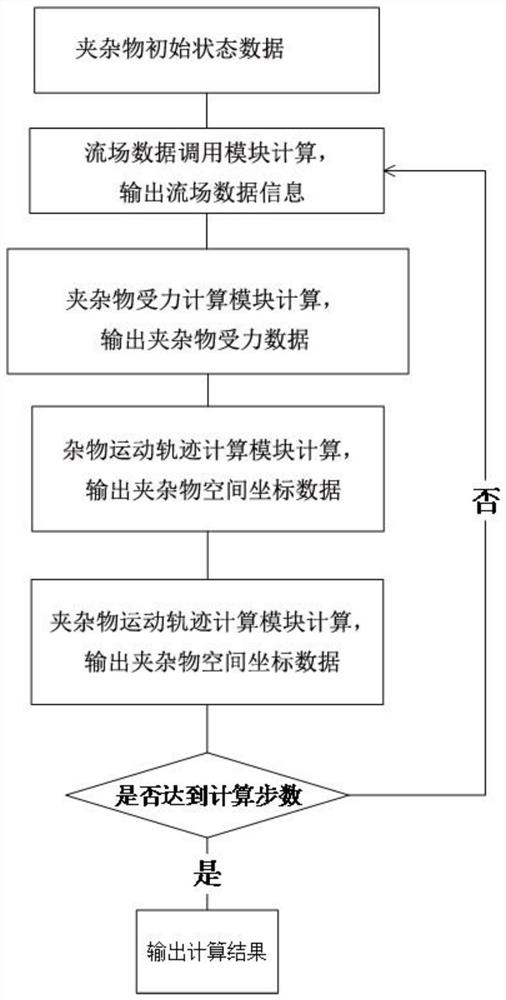

[0101] refer to figure 2 , in this embodiment, a method for simulating the movement trajectory of solid inclusions in molten steel is provided, the simulation method can calculate the movement trajectory of inclusions in molten steel by using the above-mentioned system, and the The trajectory includes the three-dimensional coordinates of the inclusion space at each moment, and the three-dimensional velocity of the inclusion in the flow field at each moment.

[0102] In this embodiment, the simulation method includes the following steps:

[0103] S1, saving the initial state data of the inclusions in the initial state data storage module of the inclusions, and setting the number of calculation steps;

[0104] S2, the control module monitors the number of steps, and according to the set number of calculation steps, circulates through the flow field data call module, the inclusion force calculation module and the inclusion movement track calculation module to calculate, and cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com