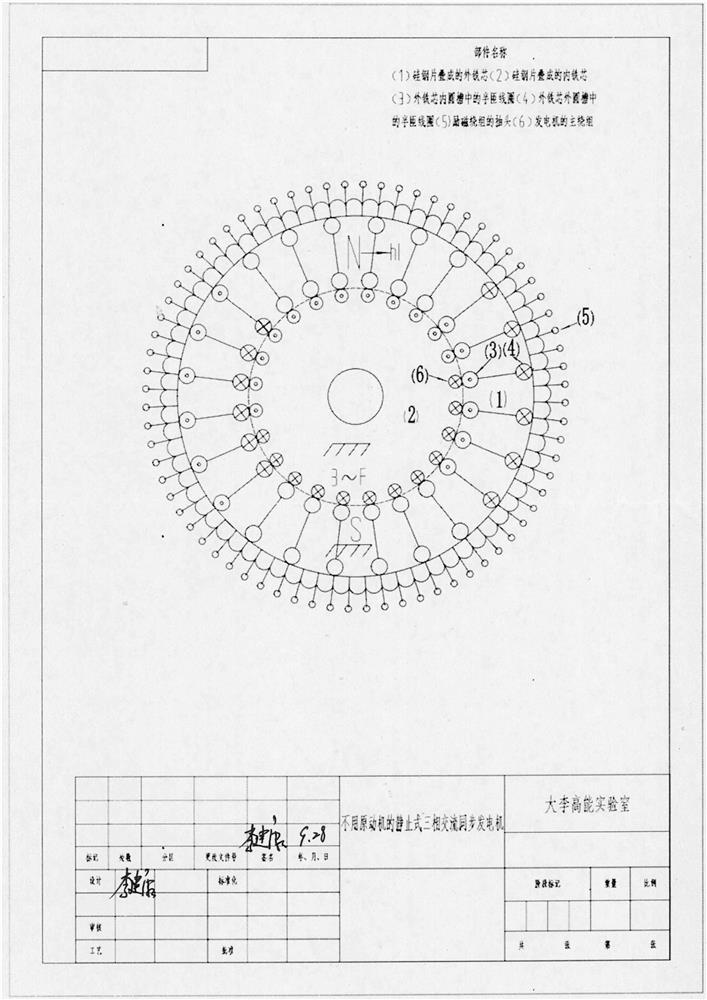

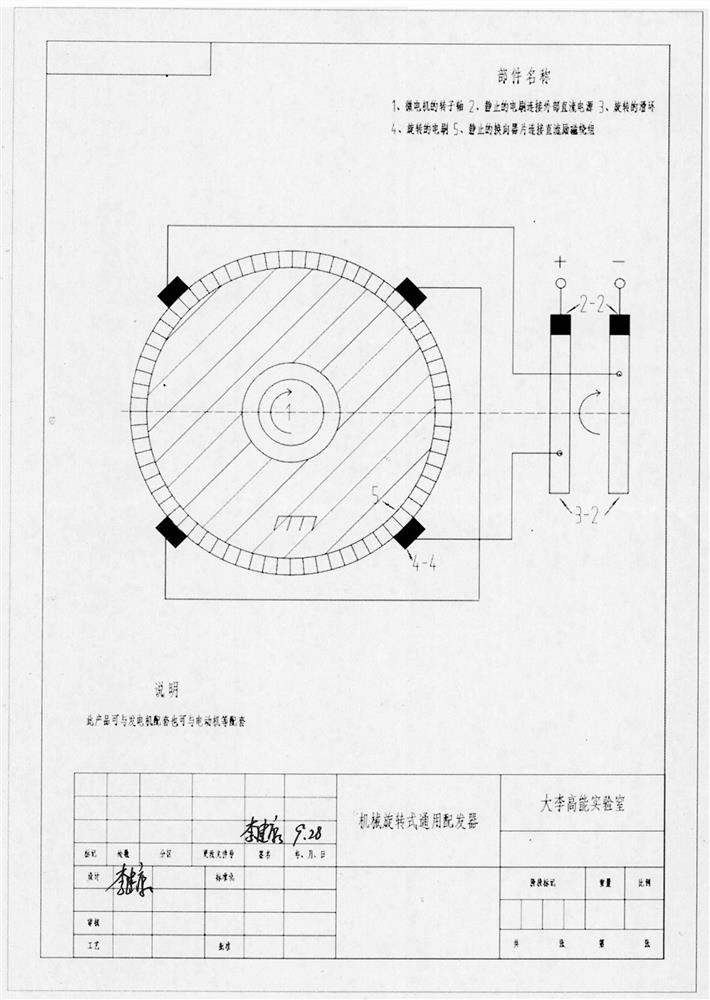

Static three-phase alternating-current synchronous generator without prime mover

A synchronous generator, three-phase AC technology, applied in the direction of electromechanical devices, shape/style/structure of winding conductors, electrical components, etc., can solve problems such as polluting the environment, incapable of large-scale manufacturing, and polluting the air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The manufacturing process, process and method of the static three-phase AC synchronous generator without prime mover of the present invention, the material is the same as that of the existing motor, and silicon steel sheets are stacked to form an annular iron core (1) with grooves (3) in the inner circle as designed There is a groove (4) on the outer circle, and a laminate of 3-8 mm is added to the two ends of the lamination. The shape of the laminate is the same as that of the silicon steel sheet, and the thin plate can be stacked to the required thickness. The half-turn wire (4) in the slot (4) is insulated well, and the wire can be wound. The winding method adopts the half-turn wire (3) in the inner slot and the half-turn wire (4) in the outer slot. The method of radial winding between wires (the purpose of designing radial winding is very clear, first, to reduce the resistance of the excitation winding, second, to minimize the loss of the original small excitation en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap