car body structure

A body and automobile technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of increased manufacturing cost, achieve the effect of ensuring strength and realizing light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

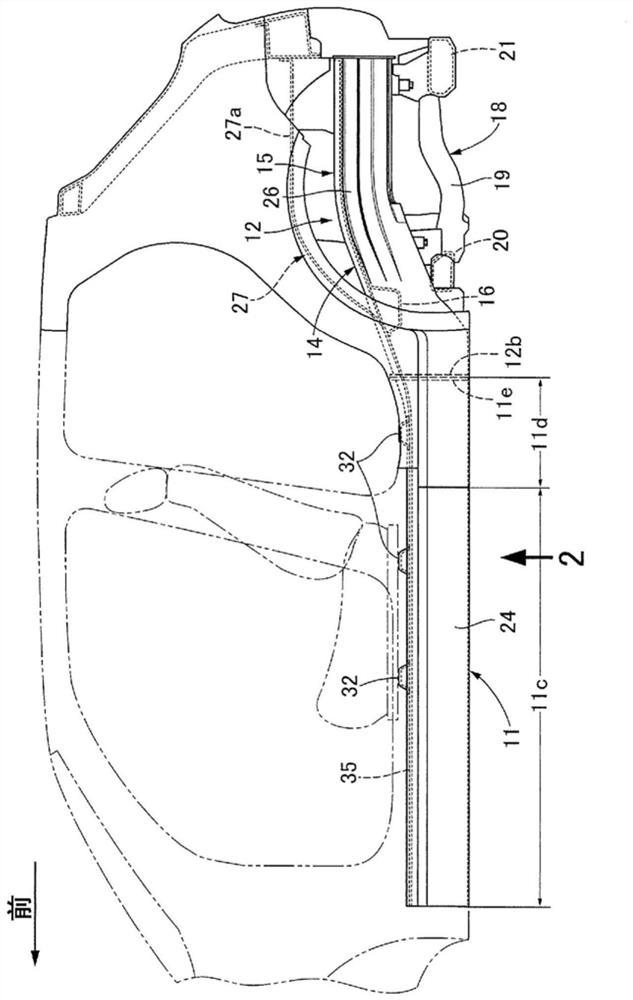

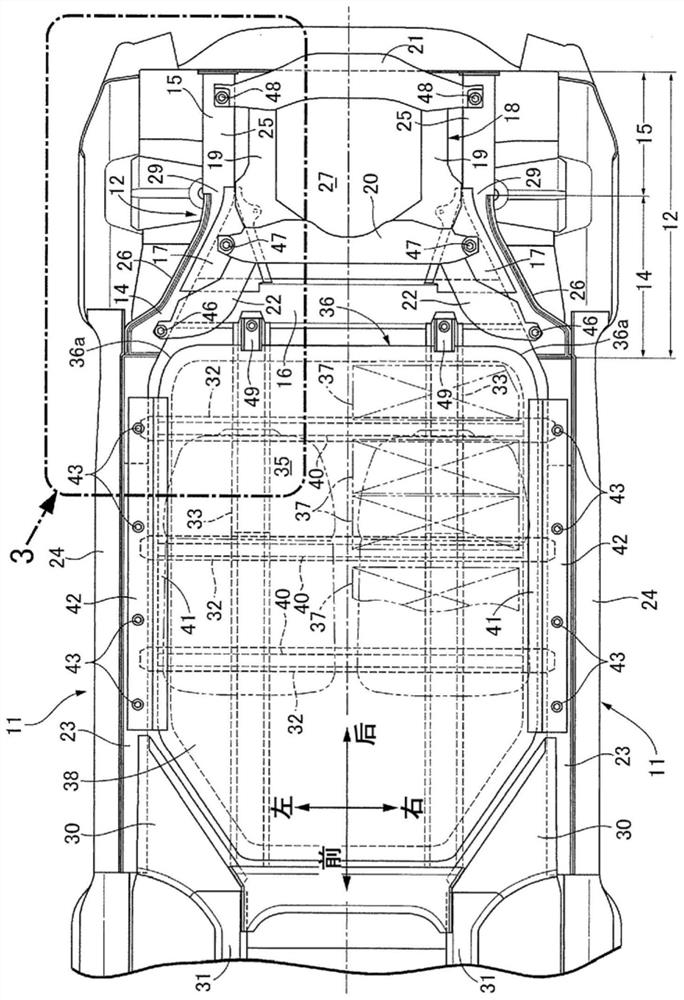

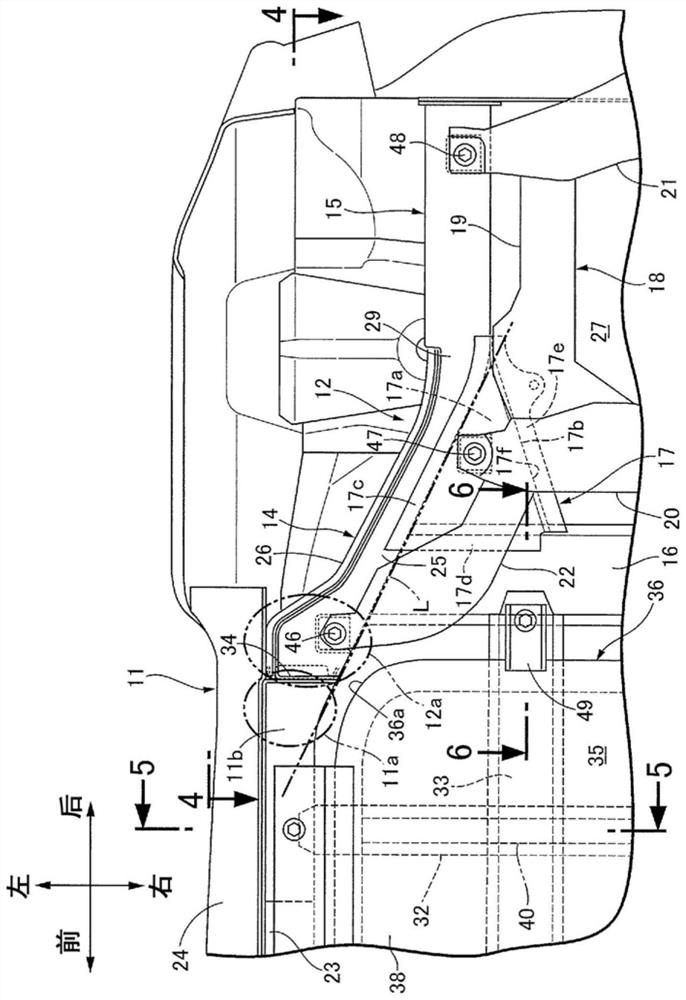

[0044] like Figure 1-Figure 3 As shown, a pair of left and right side members 11 are arranged in the front-rear direction on the body side of the electric vehicle, and a pair of left and right rear frames 12 are connected to the rear ends of the left and right side members 11 . The rear frame 12 includes a front inclined portion 14 and a rear horizontal portion 15 . The inclined portion 14 extends rearward from the rear end of the side member 11 toward the inner and upper sides in the vehicle width direction, and the horizontal portion 15 is straight from the rear end of the inclined portion 14 . extends backwards. The inclined portions 14 of the left and right rear frames 12 are connected by a rear cross member 16 extending in the vehicle width direction, and the rear side of the rear cross member 16 and the inner side of the inclined portion 14 in the vehicle width direction are connected by a triangular-shaped reinforcing member 17 in plan view. connected and strengthened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com