Preparation method and application of lactoferrin peptide enzymatic hydrolysate with antibacterial activity

A technology of lactoferrin and peptide enzymatic hydrolyzate, which is applied in the field of preparation of lactoferrin peptide enzymatic hydrolyzate, can solve the problem of limited enzymatic hydrolysis efficiency of lactoferrin active peptide enzymatic hydrolyzate, large amount of pepsin used, high preparation cost, etc. problem, achieve the effect of reducing preparation time, reducing preparation cost, and strong antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

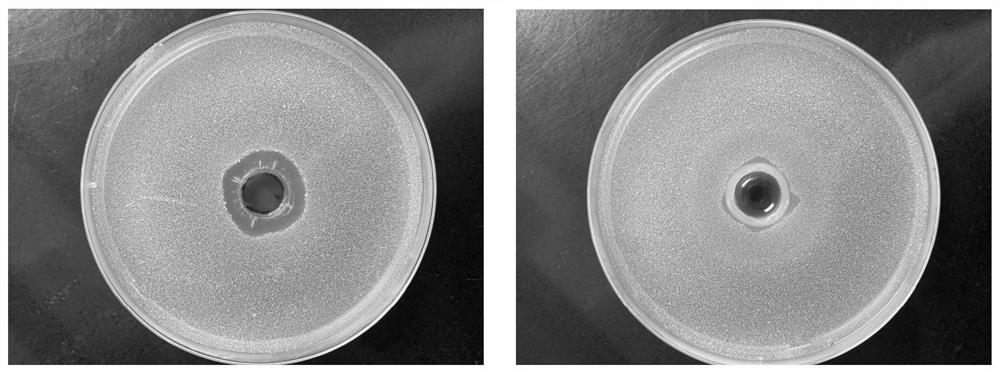

Image

Examples

Embodiment 11

[0020] Preparation by the method of the present invention: mix lactoferrin and deionized water (1:15) to prepare lactoferrin aqueous solution; use HCl solution to adjust the pH of the system to 2.3 to obtain lactoferrin acidic solution; The ferritin acidic solution was subjected to steam explosion treatment with a pressure of 0.4MPa and a holding time of 0.5min; then the above-mentioned lactoferrin acidic solution was subjected to ultrasonic treatment with an ultrasonic power of 180W and an ultrasonic time of 2s; pepsin (20U / 10mL) Add it to the above lactoferrin solution, put it in a water bath at 37°C for 5 minutes, then cool it to 4°C; add NaOH solution to adjust the pH of the system to 7, then centrifuge at 3000rpm to obtain the supernatant, and obtain the lactoferrin active peptide hydrolyzate A1 .

Embodiment 12

[0022] Preparation by the method of the present invention: mix lactoferrin and deionized water (1:5) to prepare lactoferrin aqueous solution; use HCl solution to adjust the pH of the system to 1.2 to obtain lactoferrin acidic solution; The ferritin acidic solution was subjected to steam explosion treatment with a pressure of 1.0MPa and a holding time of 0.2min; then the above-mentioned lactoferrin acidic solution was subjected to ultrasonic treatment with an ultrasonic power of 300W and an ultrasonic time of 6s; pepsin (30U / 10mL) Add it to the above lactoferrin solution, put it in a water bath at 40°C for 10 minutes, then cool to 2°C; add NaOH solution to adjust the pH of the system to 6.5, and then centrifuge at 2500rpm to obtain the supernatant to obtain lactoferrin active peptide hydrolyzate A2 .

Embodiment 13

[0024] Preparation by the method of the present invention: mix lactoferrin and deionized water (1:30) to prepare lactoferrin aqueous solution; use HCl solution to adjust the pH of the system to 3 to obtain lactoferrin acidic solution; The ferritin acidic solution was subjected to steam explosion treatment with a pressure of 0.2 MPa and a holding time of 3 min; then the above-mentioned lactoferrin acidic solution was subjected to ultrasonic treatment with an ultrasonic power of 150 W and an ultrasonic time of 4 s; adding pepsin (3 U / 10 mL) Put it into the above lactoferrin solution, put it in a water bath at 35°C for 8 minutes, then cool to 6°C; add NaOH solution to adjust the pH of the system to 7, and then centrifuge at 1000rpm to obtain the supernatant to obtain lactoferrin active peptide hydrolyzate A3.

[0025] control group

[0026] Mix lactoferrin and deionized water (1:15) to prepare a lactoferrin aqueous solution; use HCl solution to adjust the pH of the system to 2.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com