Clamping type polishing equipment for synchronous polishing of inner and outer walls of stainless steel pipe

A stainless steel tube, inner and outer wall technology, applied in grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve problems such as damage, speed up the progress of stainless steel tube polishing, etc., achieve convenient operation and improve polishing efficiency , the effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

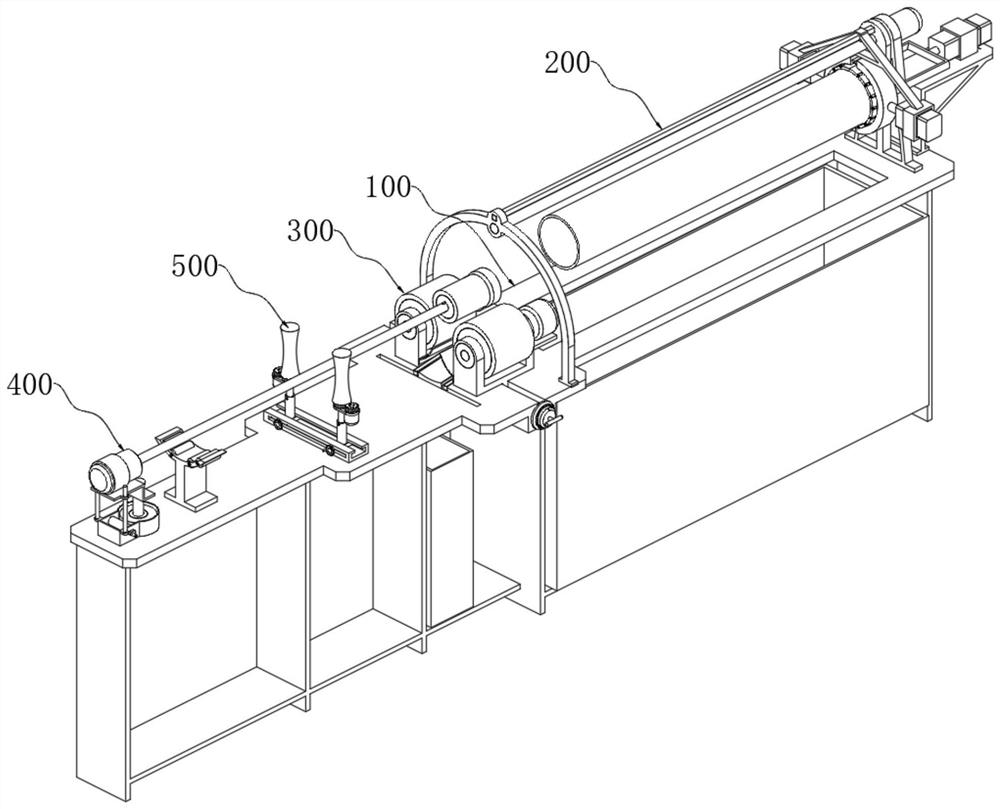

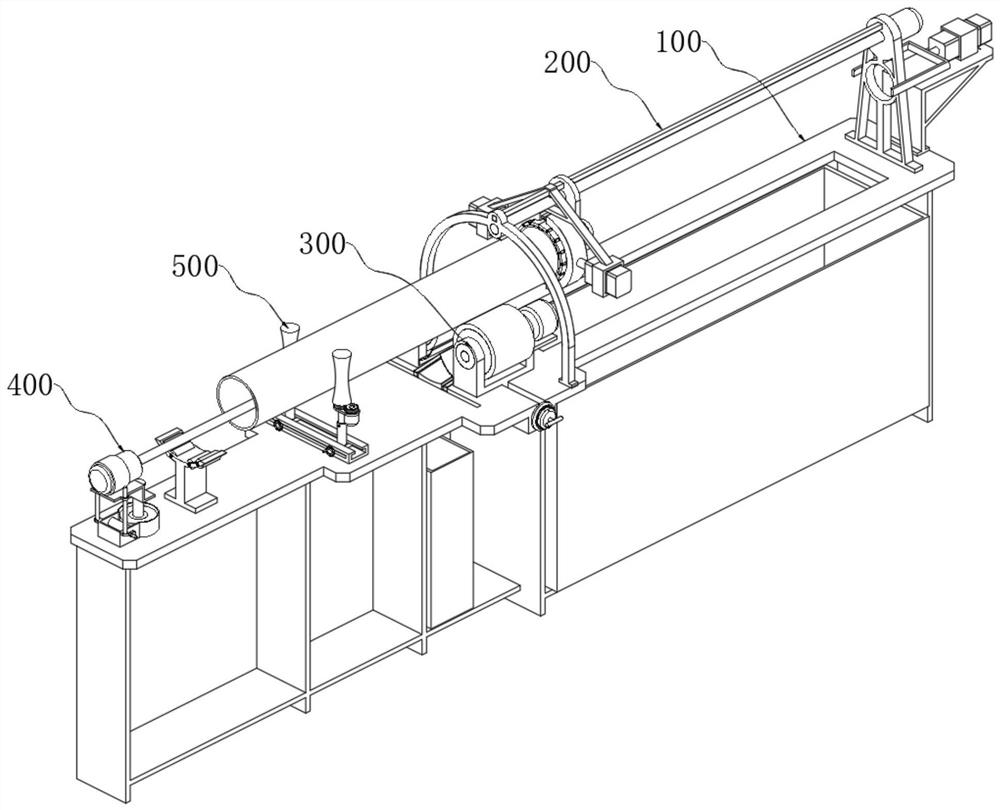

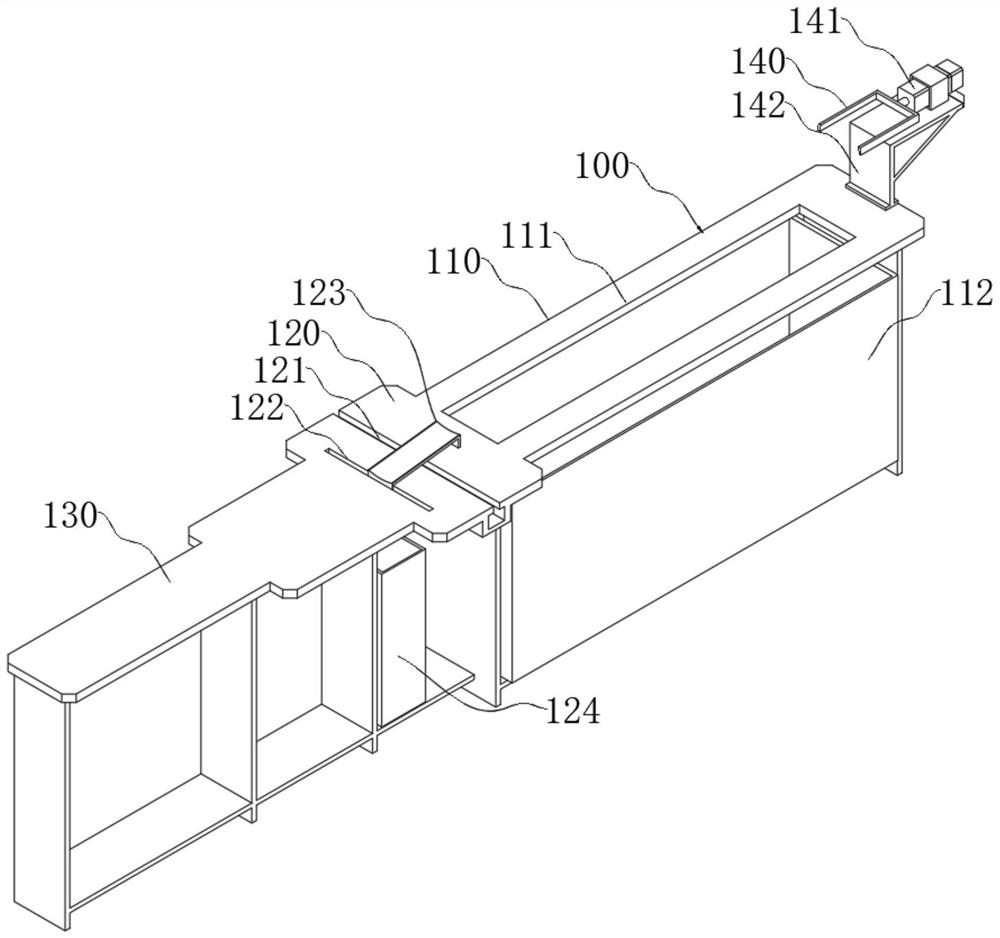

[0060] see Figure 1 to Figure 16 As shown, the present invention provides a clamping polishing device for synchronously polishing the inner and outer walls of stainless steel pipes, including a processing table 100. The processing table 100 is composed of a clamping table 110, a polishing table 120, and a loading table 130 from front to back. The processing table The bottom surface of 100 is vertically welded with several support plates for supporting the processing operation of the stainless steel pipe on the processing table 100 . Above the clamping table 110 is provided a clamping mechanism 200 for clamping and translating the stainless steel tube, for clamping the stainless steel tube to the polishing table 120 for polishing. The clamping mechanism 200 is composed of a bracket set 220 fixed on the top surface of the clamping platform 110 and a clamping assembly 210 reciprocating and linearly moving under the bracket set 220 . The bracket group 220 comprises a front brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com