Buoy for marine environment monitoring and sampling

A marine environment monitoring and buoy technology, which is applied in the direction of buoys, sampling devices, floating buildings, etc., can solve problems such as prone to dumping, damage to floating tanks, and affecting monitoring results of monitoring devices, and achieve the effect of increasing service life and preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

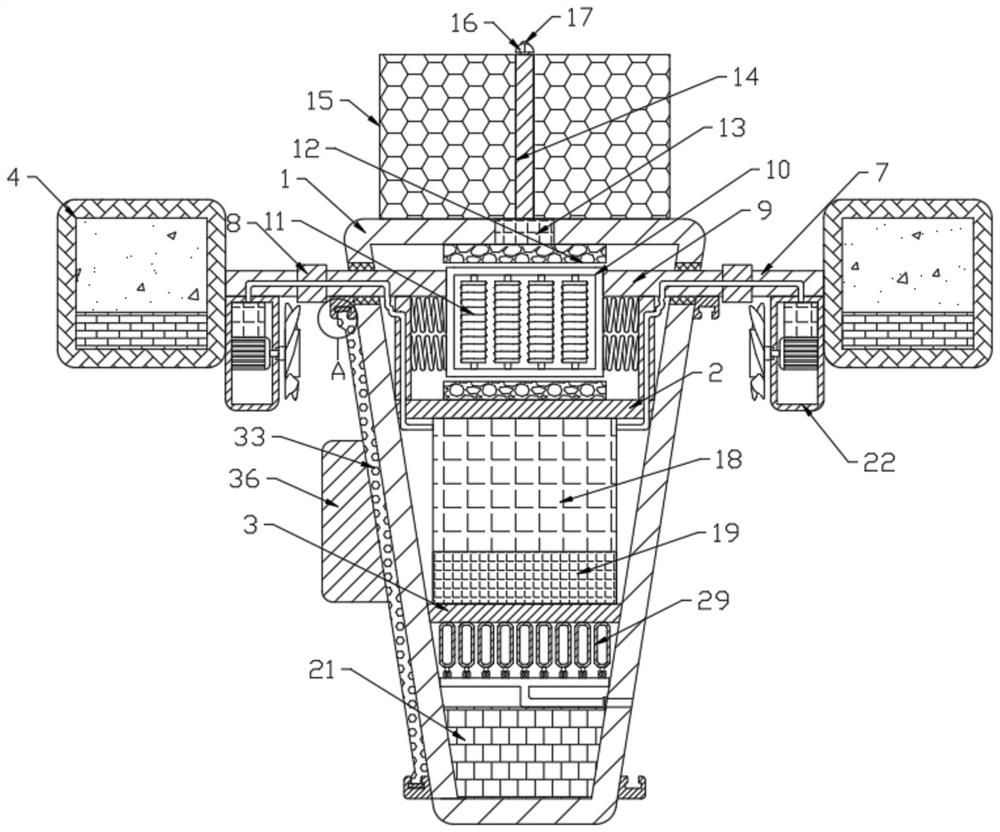

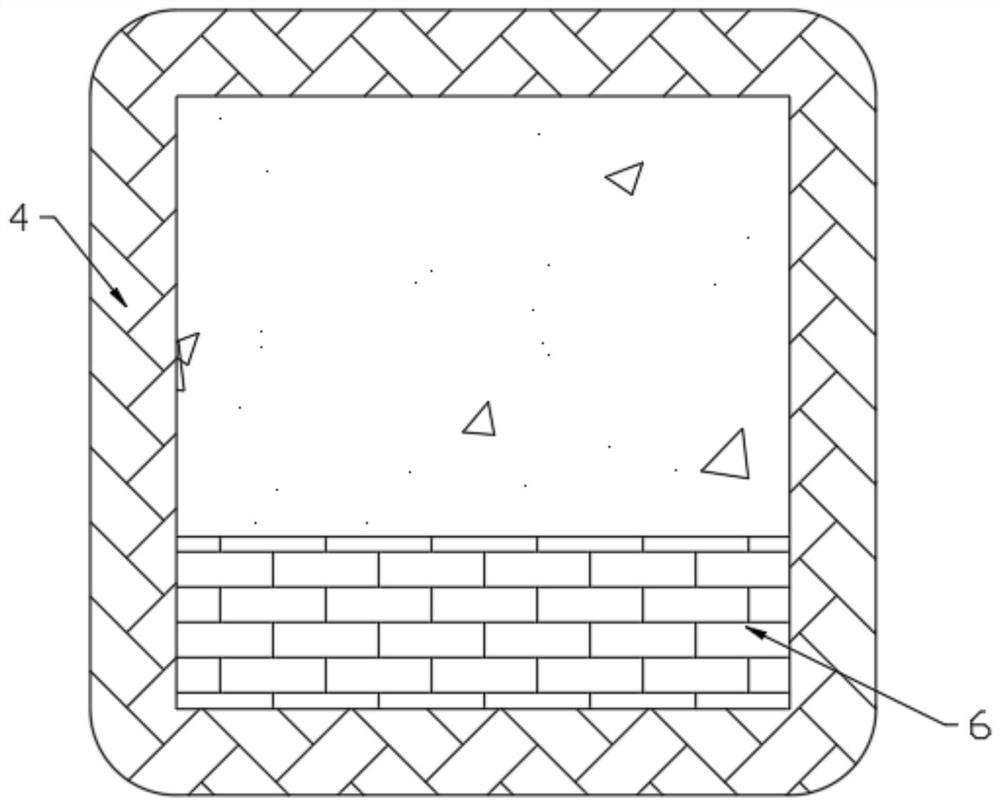

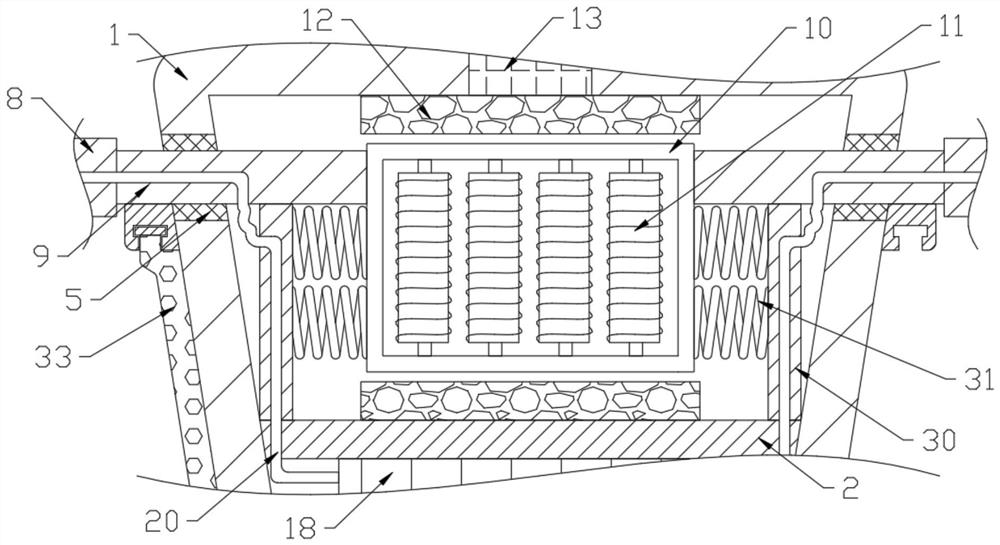

[0030] See Figure 1-7 , A buoy for marine environment monitoring and sampling, comprising a floating tank 1, a first partition 2 and a second partition 3 are arranged in the floating tank 1, a ring column 8 is provided on the outside of the floating tank 1, and the ring column 8 passes through a number of connecting rods 7 is connected to the floating component, the ring column 8 is connected to the power generating component on the upper side of the first partition 2 in the floating box 1 through the moving column 9, a signal transmitter 13 is provided in the wall of the floating box 1, and the upper side of the floating box 1 Solar power generation components are provided. A power module 18 and a master control terminal 19 are provided between the first partition 2 and the second partition 3. The lower ends of the connecting rods 7 are provided with mobile components. The power modules 18 are electrically connected to the mobile components through wires 20. In a sexual conne...

Embodiment 2

[0049] Further improvements are made on the basis of embodiment 1, and the improvements are as follows: a sealing block 5 is provided at the connection between the moving column 9 and the floating box 1, and the sealing block 5 is slidingly connected to the moving column 9, and the material of the sealing block 5 is selected as poly Tetrafluoroethylene prevents seawater from leaking into the floating box 2 at the sliding part of the movable column 9 and the floating box 1 through the setting of the sealing block 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com