AlN dielectric film with high dielectric constant and high Q value, and preparation method thereof

A high dielectric constant, dielectric thin film technology, applied in chemical instruments and methods, from condensed steam, single crystal growth, etc., to achieve the effect of improving growth quality, easy handling and cleaning, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

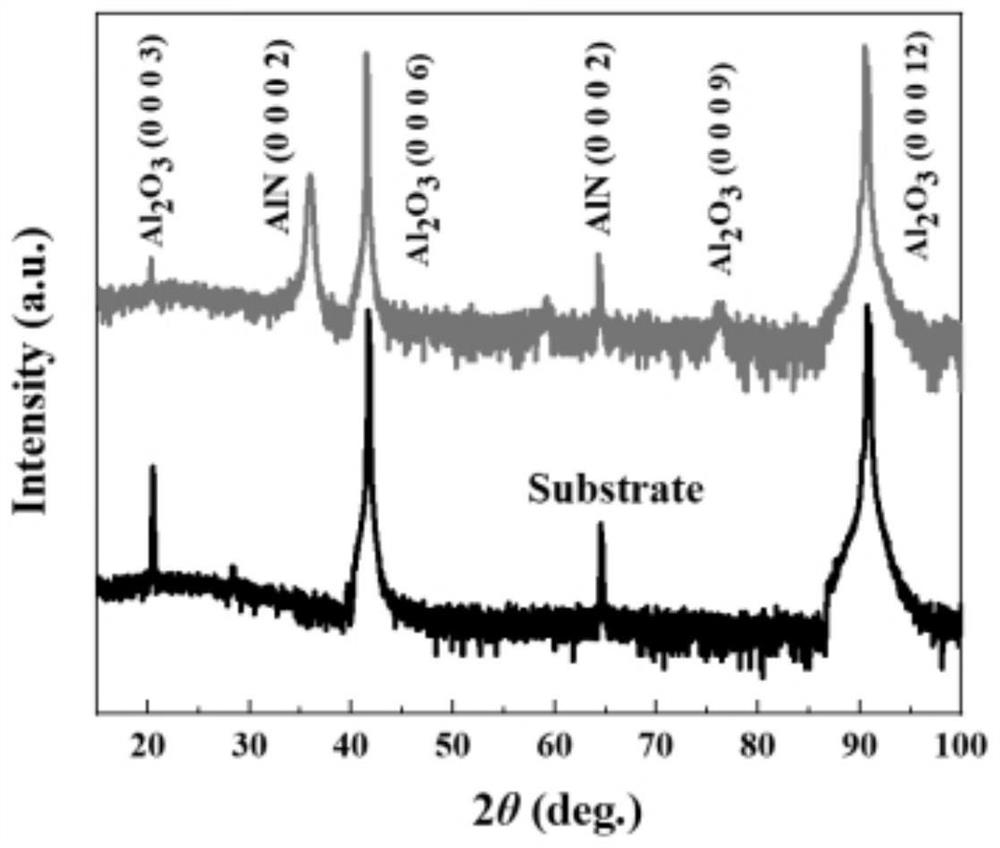

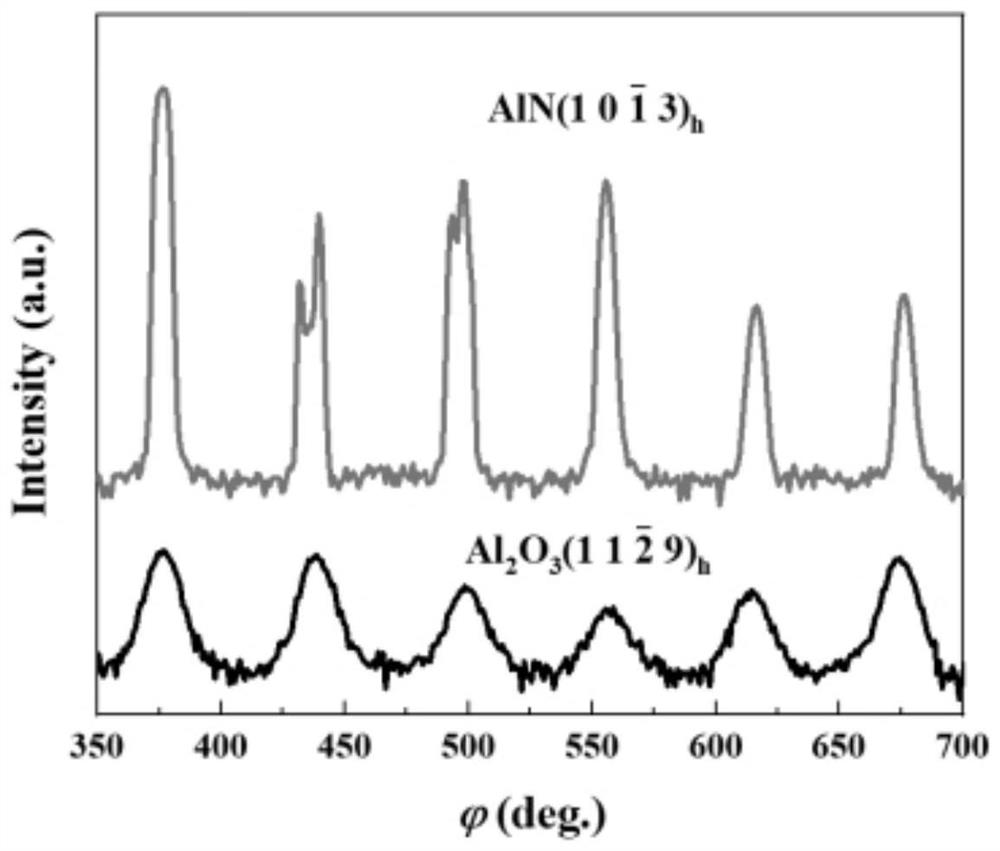

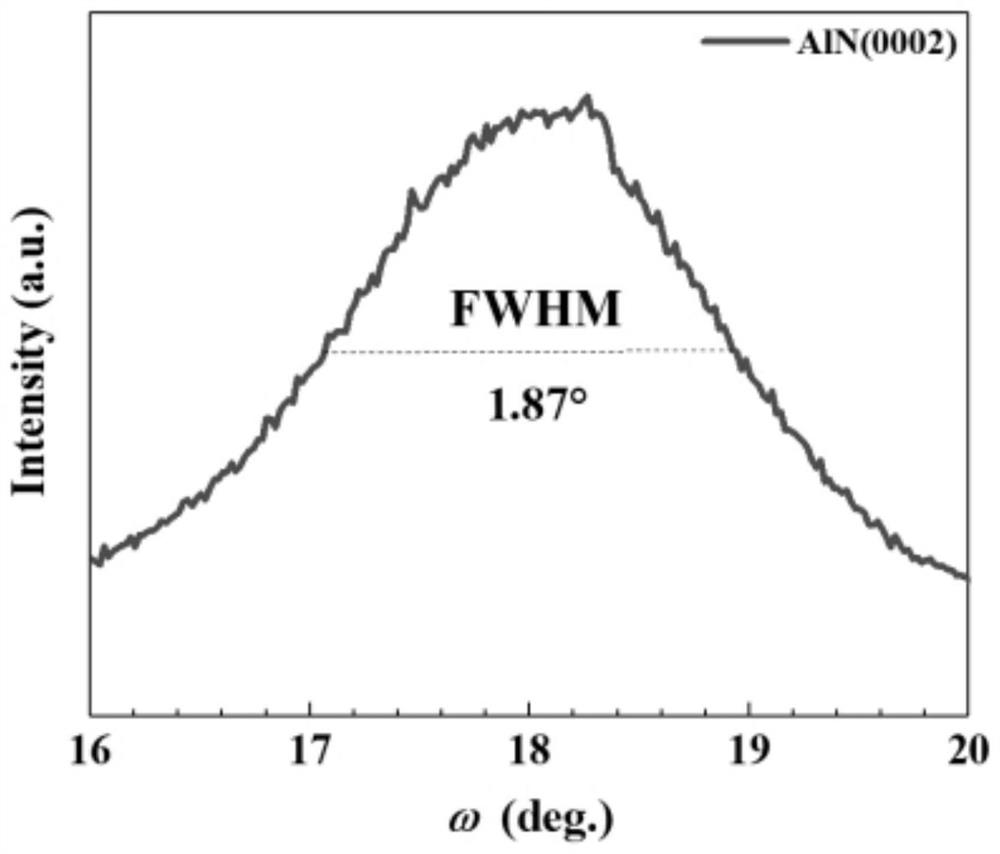

Image

Examples

preparation example Construction

[0032] The preparation method of the AlN dielectric film with high dielectric constant and high Q value of the present invention comprises the following preparation steps:

[0033] (1) Clean the sapphire substrate.

[0034] Preferably, the specific steps of cleaning the sapphire substrate are: first ultrasonically clean the sapphire substrate with an organic solvent for 12 to 16 minutes, and then rinse it with deionized water. The organic solvent is acetone, isopropanone, or alcohol, etc. ; Then put the sapphire substrate into concentrated H 2 SO 4 with concentrated H 3 PO 4 Boil in a mixed solution with a volume ratio of 3:1 for 8-10 minutes, then rinse with deionized water; finally blow dry with nitrogen for later use.

[0035] (2) heating the sapphire substrate, and in the high-purity nitrogen growth space, with 1.2~1.6J / cm 2 The laser energy density is high, and a pulsed laser is used to sputter an AlN target on the sapphire substrate.

[0036] Preferably, the AlN ta...

Embodiment 1

[0042] The preparation method of the AlN dielectric film with high dielectric constant and high Q value of the present invention is: on the surface of a clean sapphire substrate, by controlling the temperature of the sapphire substrate, the laser energy density, the vacuum degree of the growth environment, and cooling and annealing The process is to deposit and grow a single crystal AlN dielectric thin film. Specifically include the following steps:

[0043] (1) Clean the sapphire substrate.

[0044] First use an organic solvent to ultrasonically clean the sapphire substrate for 12 minutes, then rinse with deionized water; then put the sapphire substrate into 75wt% H 2 SO 4 with 85wt%H 3 PO 4 Boil in a mixed solution with a volume ratio of 3:1 for 9 minutes, then rinse with deionized water; finally blow dry with nitrogen for later use.

[0045] (2) Deposit AlN film on the surface of sapphire substrate.

[0046] Heating the sapphire substrate gradually to 700°C at a heati...

Embodiment 2

[0050] The preparation steps of the AlN dielectric thin film with high dielectric constant and high Q value in this embodiment 2 are the same as those in the embodiment 1, and the difference lies in the different condition parameters in the preparation process.

[0051] (1) Clean the sapphire substrate.

[0052] First use the organic solvent to ultrasonically clean the sapphire substrate for 14min, then rinse with deionized water; then put the sapphire substrate into 75wt%H 2 SO 4 with 85wt%H 3 PO 4 Boil in a mixed solution with a volume ratio of 3:1 for 10 minutes, then rinse with deionized water; finally blow dry with nitrogen for later use.

[0053] (2) Deposit AlN film on the surface of sapphire substrate.

[0054] Heating the sapphire substrate to 750°C gradually at a heating rate of 9°C / min, and growing in high-purity nitrogen gas at a rate of 1.5J / cm 2 On the surface of the sapphire substrate, an AlN ceramic target with a purity of 99.99% is sputtered by a pulsed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com