Tire section sample treatment method and sample obtained through method

A processing method and cross-section technology, applied to the processing method and the sample field obtained by the method, can solve the problems of boundary confirmation, difficult extraction of measurement targets, strong boundary ambiguity, etc., and achieve economical materials and equipment, easy preservation, and reduction of boundaries. blur effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Process of the present invention:

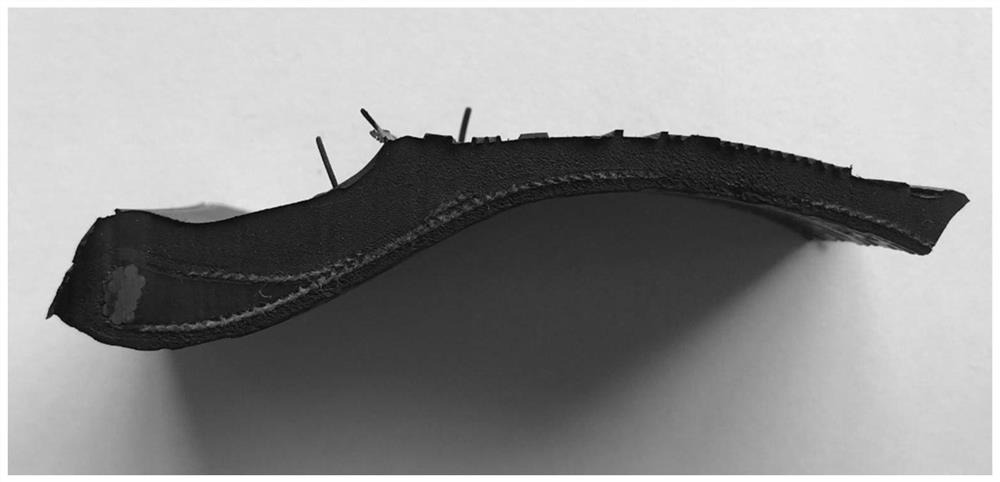

[0023] 1. Use a section cutting machine to cut out the section required for analysis. The size of the section is guaranteed to be placed in a container that meets the requirements, and the section has a complete analysis interface, such as figure 1 shown;

[0024] 2. Select ordinary sulfur powder (non-oil-filled), put it in a container with good heat conduction, and cover the container. Put the container in a constant temperature oil bath with stirring function, set the temperature of the oil bath at 120°C, and turn on the stirring function;

[0025] 3. After the sulfur is fully dissolved, place the cross-section in the sulfur solution, keep the oil bath at 120°C and stir, and treat for 24 hours;

[0026] 4. After the treated section is stored under laboratory conditions (temperature: 24°C, humidity: 52% RH) for 24 hours, use a grinder with a grinding wheel particle size of 40um to grind the surface of the section until the surface ...

Embodiment 2

[0029] Except that sulfur adopts 10% oil-extended sulfur powder, all the other processes are consistent with embodiment 1.

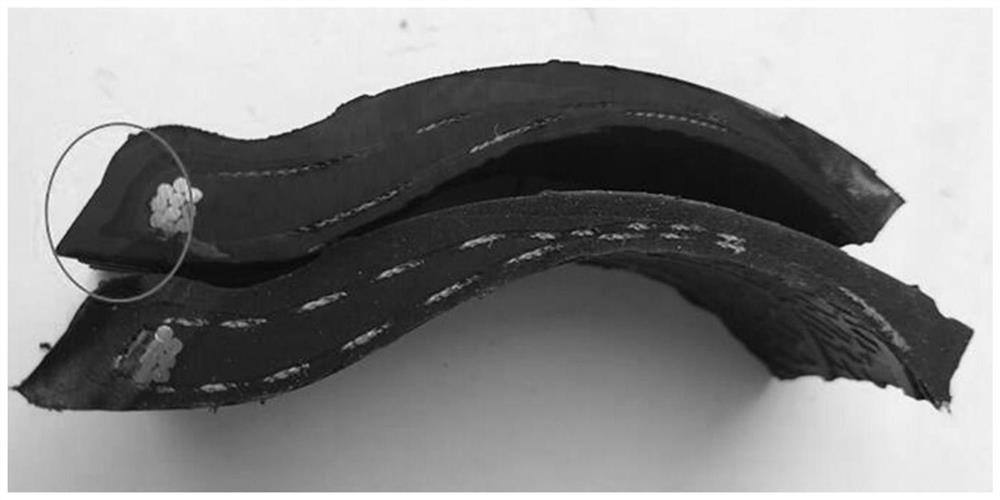

[0030] Cross-sections before and after treatment image 3 As shown, after the section is processed, the interface fuzziness is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com