Knitting machine host multi-servo-motor synchronous control system and control method

A technology of servo motor and synchronous control, which is applied in general control system, control/regulation system, program control in sequence/logic controller, etc. It can solve problems such as difficult operation and synchronous operation of multiple servo motors, and achieve stable speed , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

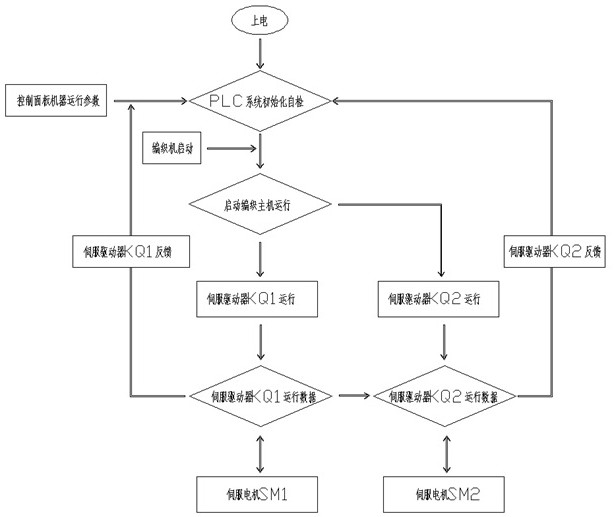

[0045] Embodiment 1: The multi-servomotor synchronous control of the main machine of the knitting machine of the present invention includes a servomotor synchronous control system and a control method based on the servomotor synchronous control system.

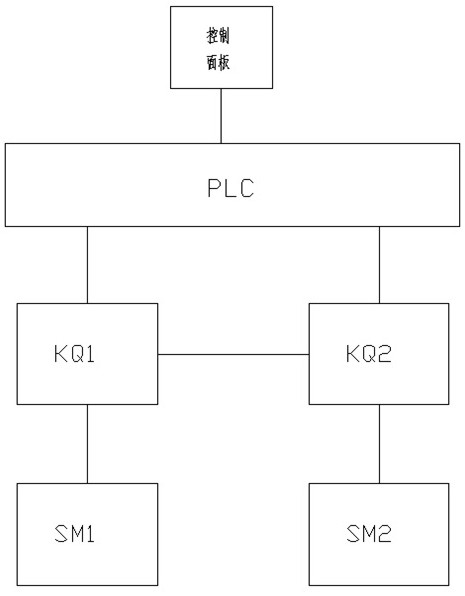

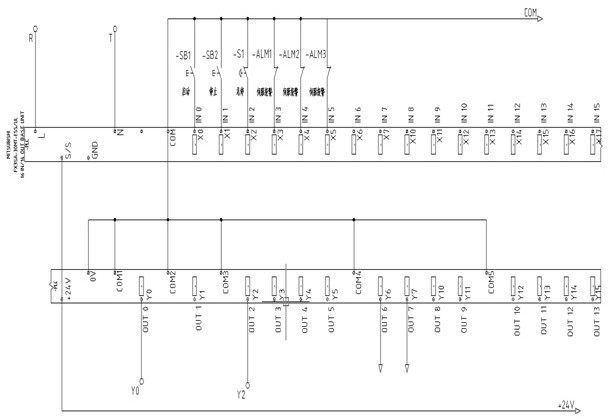

[0046] The servo motor synchronous control system includes: control panel, PLC and servo drive device. The control panel is connected to the input terminal of PLC to set the internal parameters of PLC; the output terminal of PLC is connected to the servo drive device to control the servo drive device to drive the knitting machine. run and speed.

[0047] The said servo drive device is no less than two sets with the same structure; including: a servo drive and a servo motor, the output end of the servo drive is connected to the servo motor to form a set of servo drive devices, and the servo drive drives the servo motor to run;

[0048] The two sets of servo drive devices include: a first servo driver KQ1, a second servo driver ...

Embodiment 2

[0070] Embodiment 2: This embodiment discloses a synchronous control system that controls no less than two sets of servo drive devices to drive the normal operation of the knitting machine. When the load of the knitting machine is too heavy, the use of two sets of servo drive devices cannot meet the normal operation of the machine , the synchronous control system of the present invention can be expanded to use three servo drive devices to run synchronously, or to use more sets of servo drive devices to run synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com