Foot cover and method for manufacturing foot cover

A manufacturing method and technology of sock covers, which can be applied to socks, pantyhose, clothing, etc., can solve problems such as sinking into the skin and decrease in wearing comfort, and achieve the effect of inhibiting decline and inhibiting offset/falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

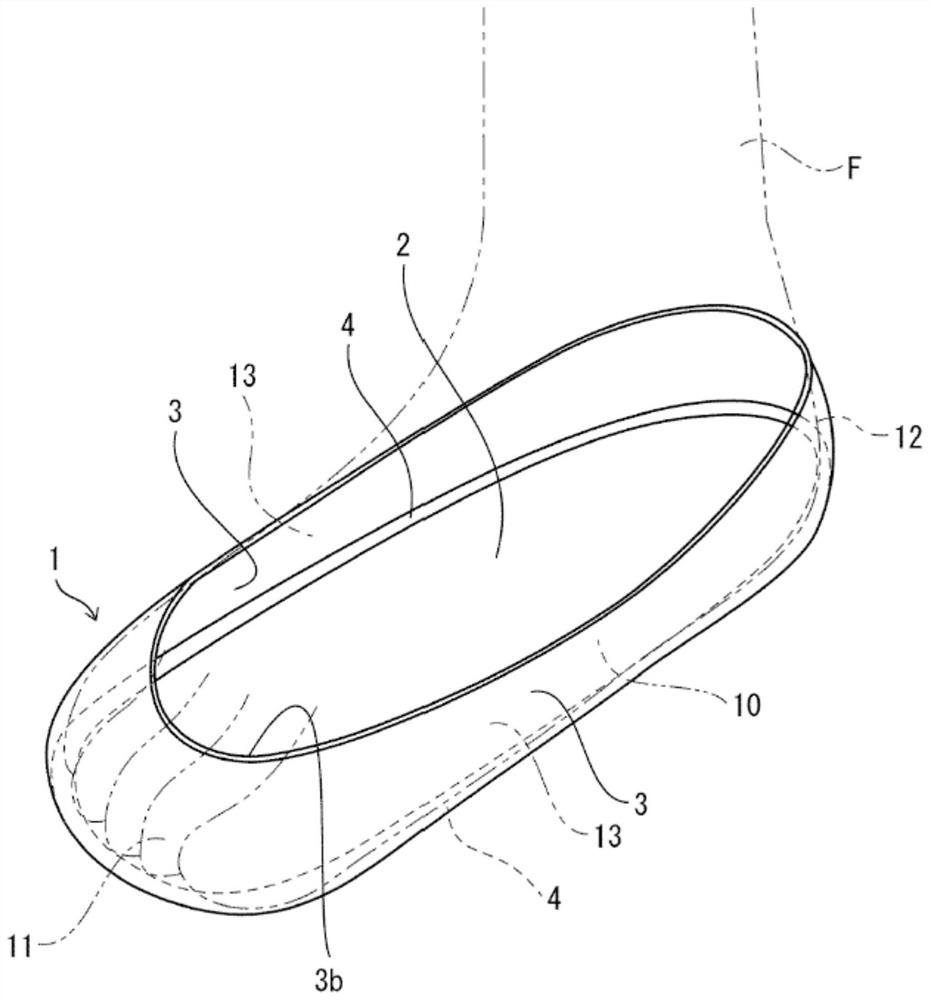

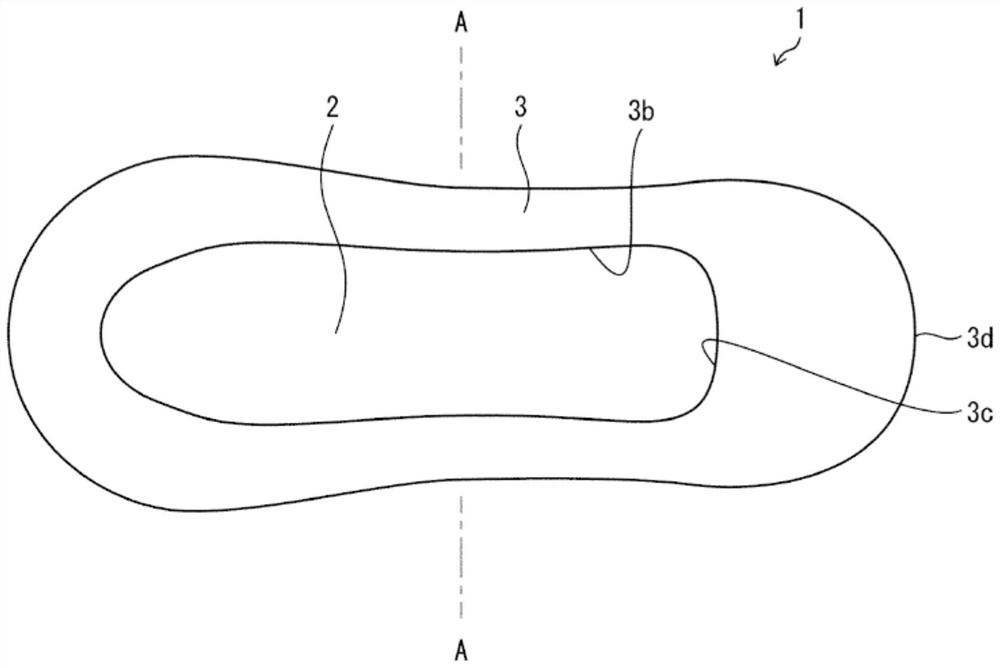

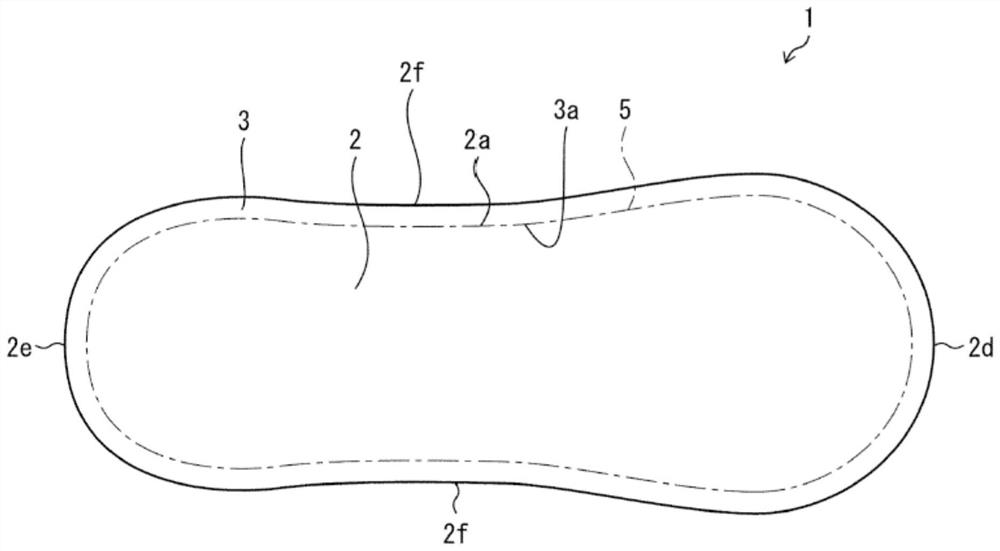

[0025] Below, based on Figure 1 ~ Figure 6 , The embodiment of the present invention will be described. In this embodiment, in order not to wear left and right errors, an example of the sock 1 that can be used in a shared manner for left and right will be described. However, it is not limited to this, and socks for left foot use and right foot use may be provided. In addition, for example, the sock 1 is in the shape of a cloth sock, but may also be in the shape of five fingers.

[0026] (Outline of Socks)

[0027] figure 1 It is a perspective view showing a state where the sock 1 according to the embodiment of the present invention is worn on the foot F. Such as figure 1 As shown, the sock 1 includes: the sole 2 of the foot, the sole 10 of the foot F; and the side part 3, the toe 11, the heel 12 of the foot F, and the two sides 13 from the toe 11 to the heel 12. This sock 1 is formed by joining the outer peripheral parts of two substantially flat fabrics constituting the bottom...

Embodiment approach 2

[0056] Regarding other embodiments of the present invention, reference is made below Figure 7 To explain. In addition, for convenience of description, components having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals, and the description thereof will not be repeated.

[0057] (Double bottom)

[0058] Figure 7 So figure 2 The end view cut from the line A-A shown. In addition, although the sock 1 is formed in a substantially flat shape, it is Figure 7 In the figure, it is three-dimensionally illustrated for convenience of description. Such as Figure 7 As shown, the foot bottom 2 may also be configured to include an inner fabric 2b contacting the foot F and an outer fabric 2c covering the inner fabric 2b from the outside. In this way, for example, a skin-friendly and air-permeable natural fiber fabric is used for the inner fabric 2b, and a synthetic fiber fabric with strength and ultrasonic welding is used for ...

Embodiment approach 3

[0062] Regarding further other embodiments of the present invention, reference is made below Picture 8 To explain. In addition, for ease of description, components having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals, and the description thereof will not be repeated.

[0063] (Structure of Socks)

[0064] Picture 8 It is a plan view showing the sock 1a of the embodiment of the present invention. Picture 8 It shows the state of turning out the socks 1a.

[0065] Such as Picture 8 As shown, the sock 1a includes a sole 2 and a side portion 30. The side part 30 includes a first side part 31 (side part) and a second side part (side part / heel part) 32. The first side surface portion 31 includes a stretchable fabric covering the toe 11 and both sides 13 of the foot F. The second side portion 32 includes a stretchable fabric covering the heel 12 of the foot F. The first side surface portion 31 and the second side s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com