Novel turbo air grader for silicon carbide micro powder

A technology of silicon carbide micropowder and air classifier, which is applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., and can solve the problems of lack of devices for controlling feeding, screening of fine powder particle size, and influence on Classification efficiency and other issues, to achieve the effect of simple and reasonable machine structure, high practical value, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

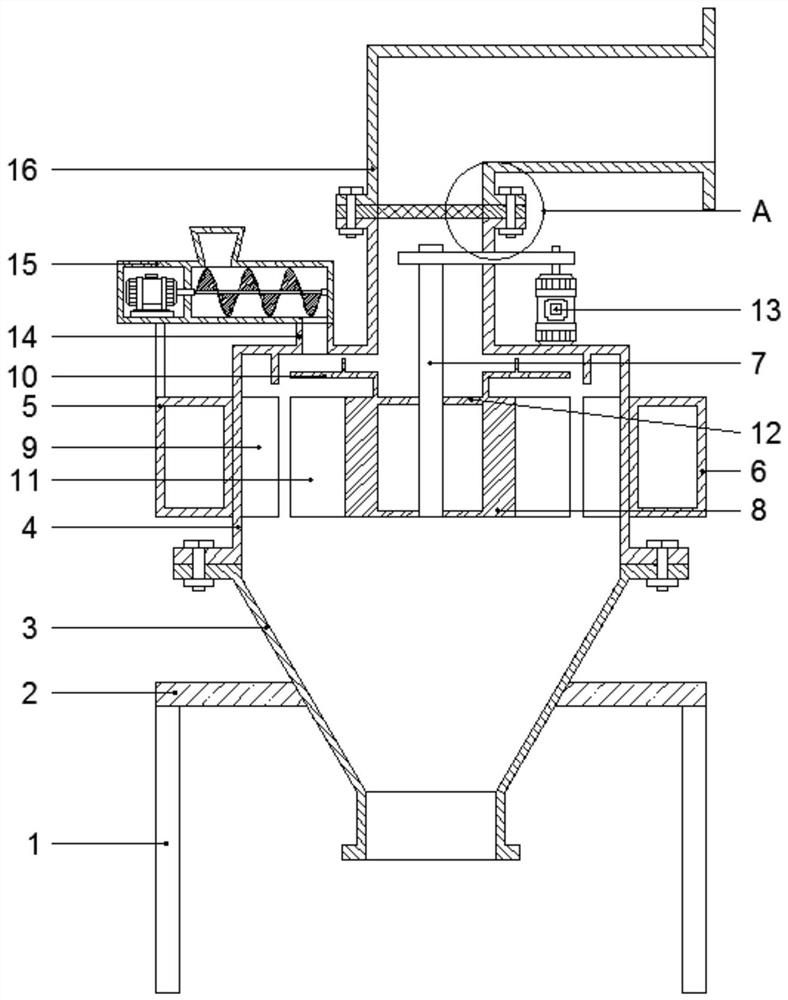

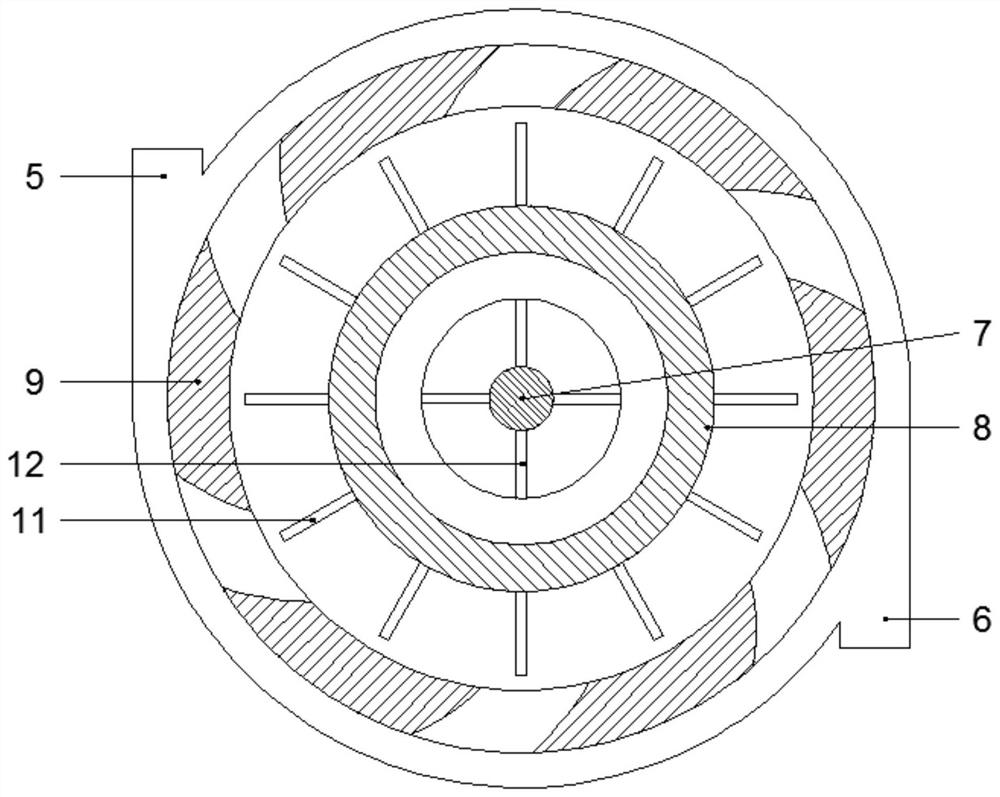

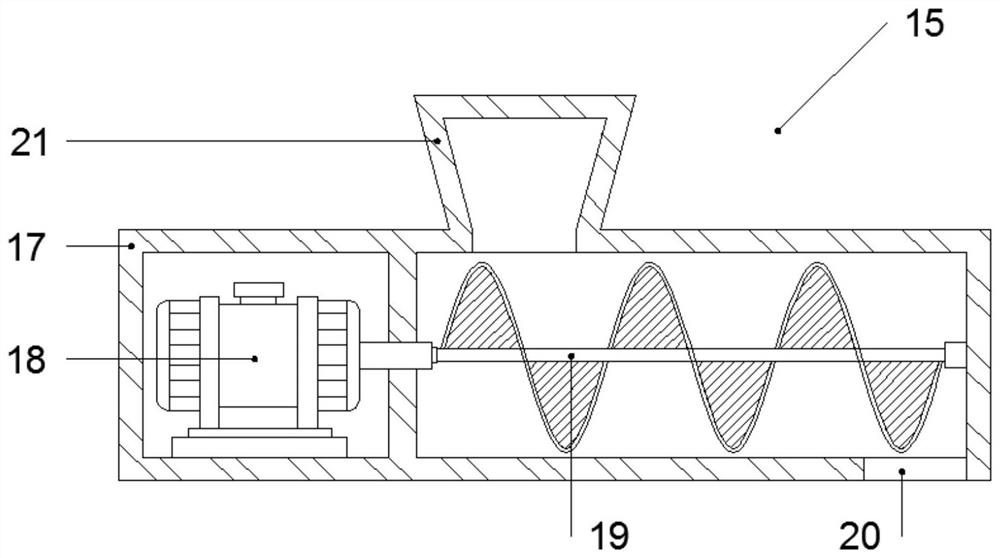

[0021] Example: such as Figure 1-4 As shown, a novel vortex air classifier for silicon carbide micropowder according to the present invention includes a support column 1, a fixed plate 2 is fixedly installed on the top of the support column 1, the fixed plate 2 runs through a blanking shell 3, and the blanking shell 3 The main housing 4 is fixedly installed on the top, the main housing 4 is provided with a rotating shaft 7 inside, the bottom of the rotating shaft 7 is covered with a rotating cage 8, the top of the rotating cage 8 is fixedly installed with a spreader 10, and the main housing 4 is provided with a volute 9. A first motor 13 is fixedly installed on the top of the main housing 4, and the first motor 13 is connected to the rotating shaft 7 through a belt. The top of the main housing 4 is provided with a feed port 14 on the side away from the first motor 13. A feeding device 15 is fixedly installed on the top of the feed inlet 14 , and a fine powder feeding pipe 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com