Liquid nitrogen conformal inner-cooling forming cutter and mounting method thereof

A technology of cold forming and liquid nitrogen, which is applied to lathe tools, manufacturing tools, accessories of tool holders, etc., can solve the problems of heavy pollution, achieve the effect of reducing work burden, avoiding easy damage of tools, and convenient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

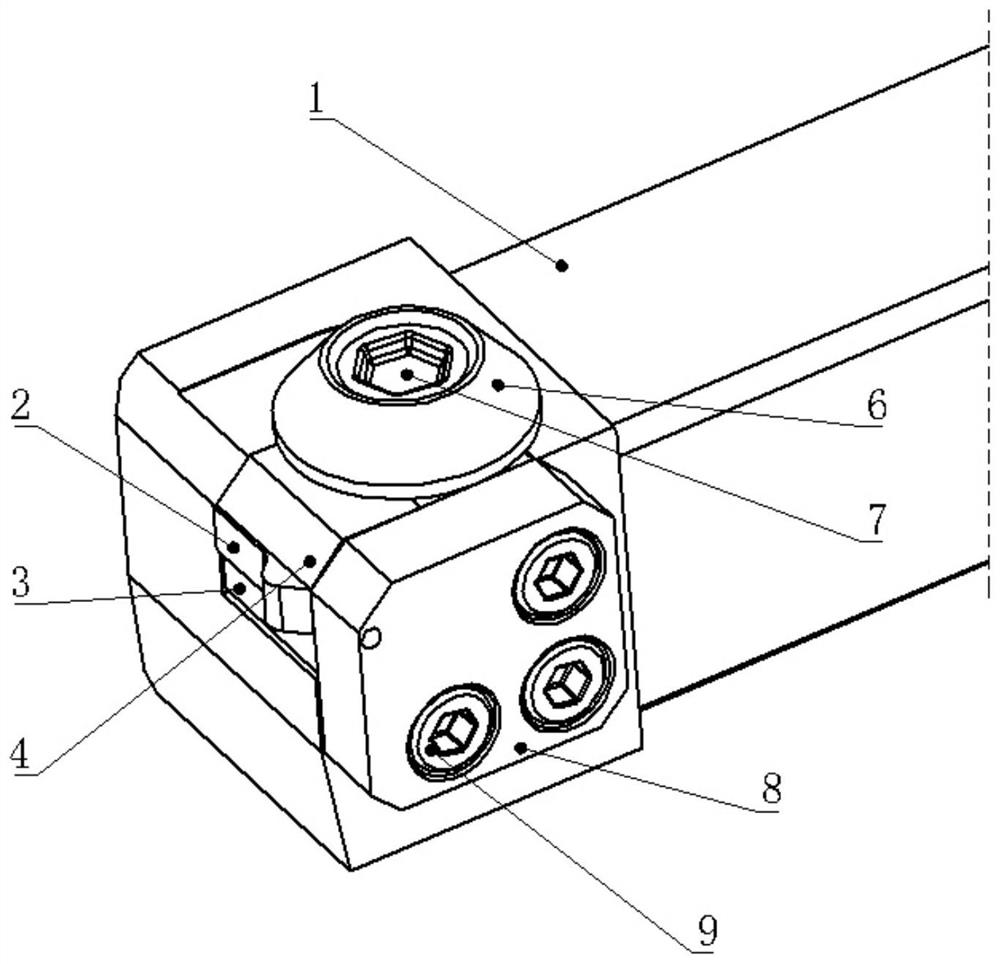

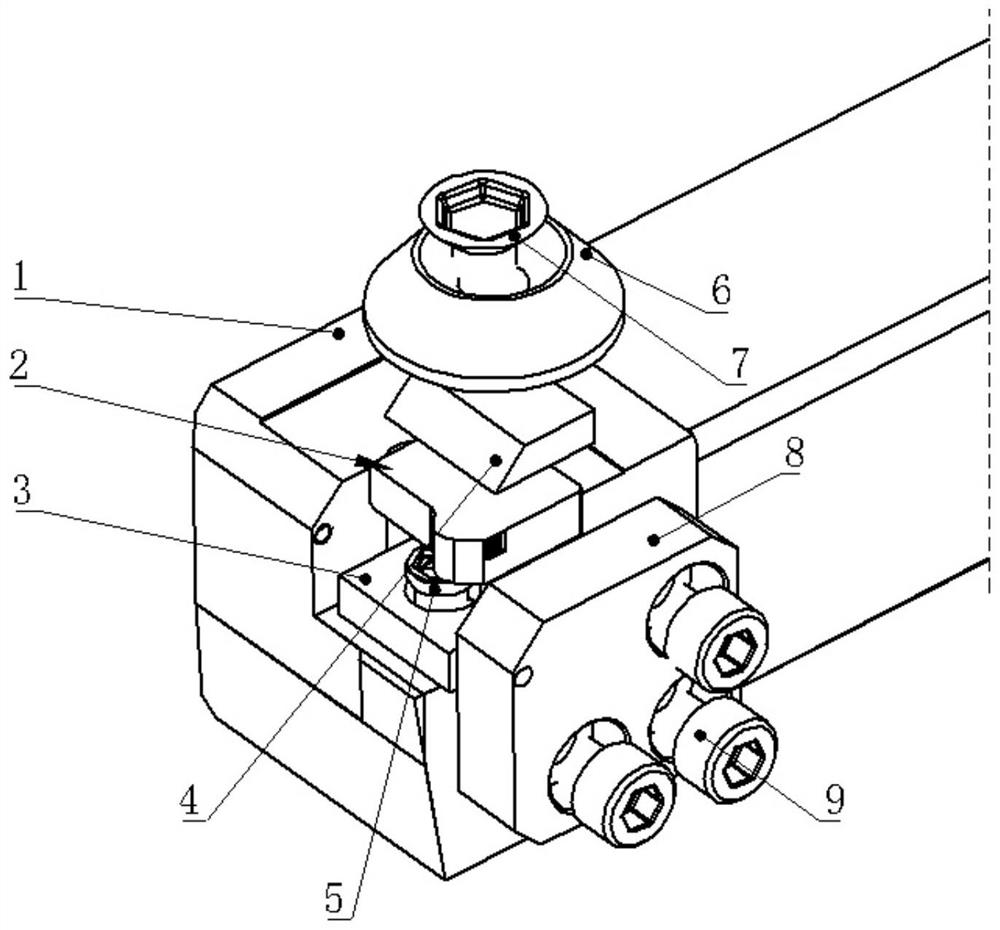

[0044] The embodiment is basically as attached figure 1 and figure 2 As shown: the liquid nitrogen conformal internal cooling forming tool in this embodiment solves the problem that the cutting edge line of the traditional forming tool is long and the external cooling cannot achieve the ideal cooling effect; at the same time, it solves the problem that liquid nitrogen is easy to make each The problem of freezing of functional parts, and the ability to recycle liquid nitrogen.

[0045] The liquid nitrogen conformal internal cooling forming tool in this embodiment includes the following parts:

[0046] A knife body 1 with a liquid nitrogen channel with a heat-insulating layer. In this embodiment, the knife body 1 has a block structure, and the surface of the knife body 1 is evenly coated with a heat-insulating layer. The heat-insulating layer can protect liquid nitrogen from flowing through the knife. The part of the cutter body 1 will not freeze when the cutter body 1 is in ...

Embodiment 2

[0061] The difference from Embodiment 1 is that there are four lateral pressure screws 9 in this embodiment, and the threaded holes corresponding to the four lateral pressure screws 9 are arranged in the shape of a "mouth", wherein the threaded hole in the upper left corner is the same as the The blade 2 limiting hole on the blade 2 is facing, so that all honeycomb holes on the blade 2 can flow out through the threaded hole. The screw located in the threaded hole is an axial hollow structure, that is, the outer side of the screw is provided with external threads, which are used to fix the side pressure plate 8 and the cutter body 1, and the axial channel of the screw communicates with the lower limit hole of the blade 2 for To make the liquid nitrogen passing through the honeycomb hole flow, the screw is called a through screw, and the axial channel of the screw is called the liquid nitrogen channel outlet.

Embodiment 3

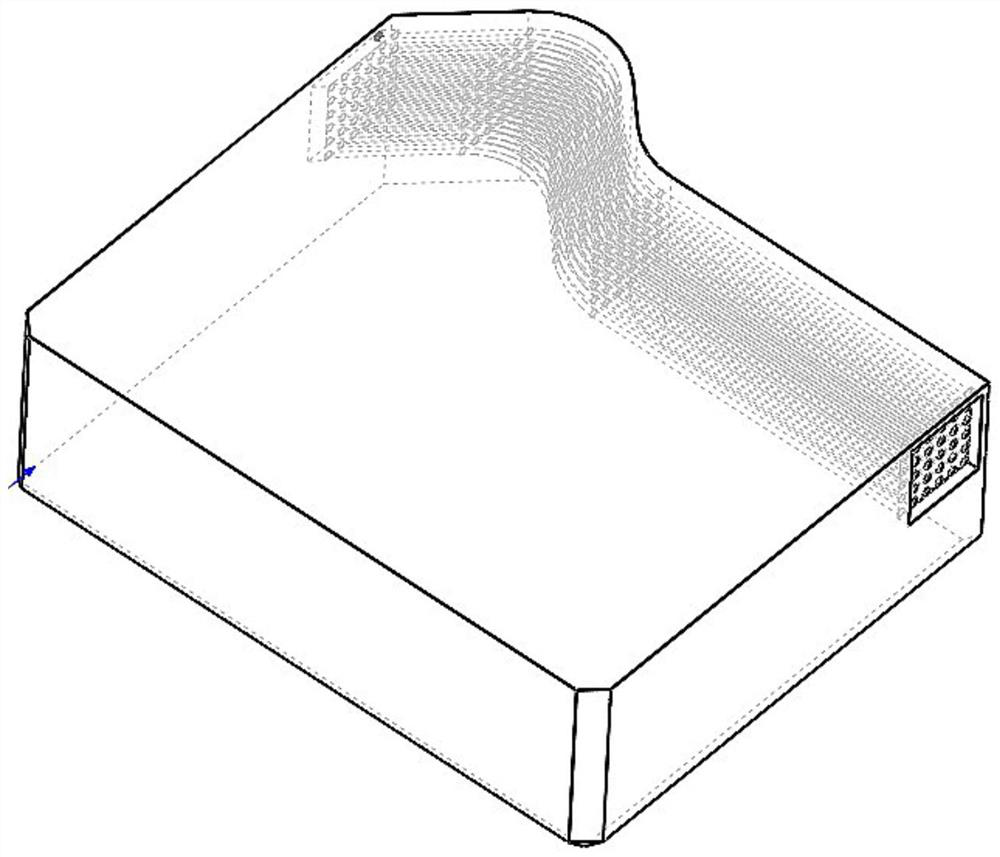

[0063] The difference from Embodiment 1 is that the heat insulation layer in this embodiment is not directly coated on the surface of the cutter body 1, such as Figure 5 As shown, the heat insulation layer in this embodiment is arranged at the end of the cutter body 1 to be in contact with the blade 2. On the position corresponding to the honeycomb hole at the rear end of the blade 2, there is a corresponding heat insulation layer on the heat insulation layer. Layer hole, the heat insulation layer hole runs through the heat insulation layer all the time, so that liquid nitrogen can be introduced into the blade 2 honeycomb holes through the heat insulation layer hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com