Efficient polishing machine provided with multiple stations

A polishing machine and multi-station technology, applied in surface polishing machine tools, machine tools suitable for grinding the edge of workpieces, grinding/polishing equipment, etc., can solve the problems of insufficient hardware efficiency and affecting the production and processing efficiency of hardware, etc. , to improve the production and processing efficiency, prevent the internal temperature from being too high, and shorten the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

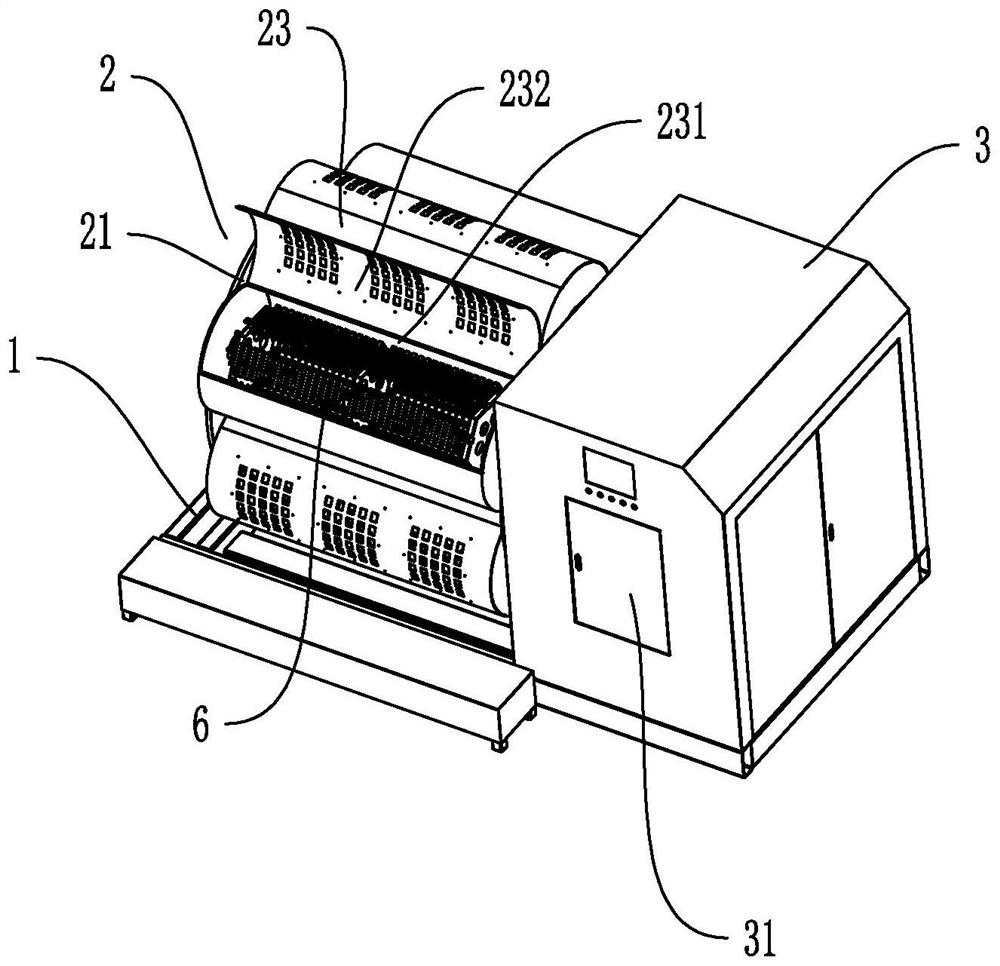

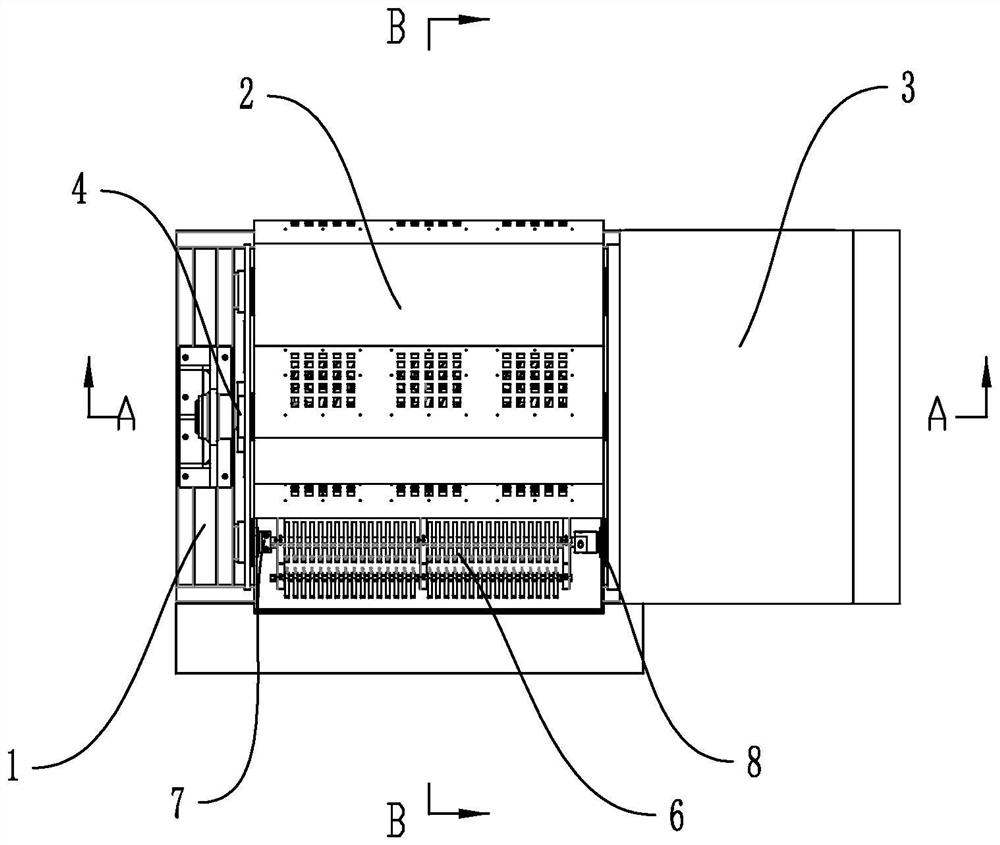

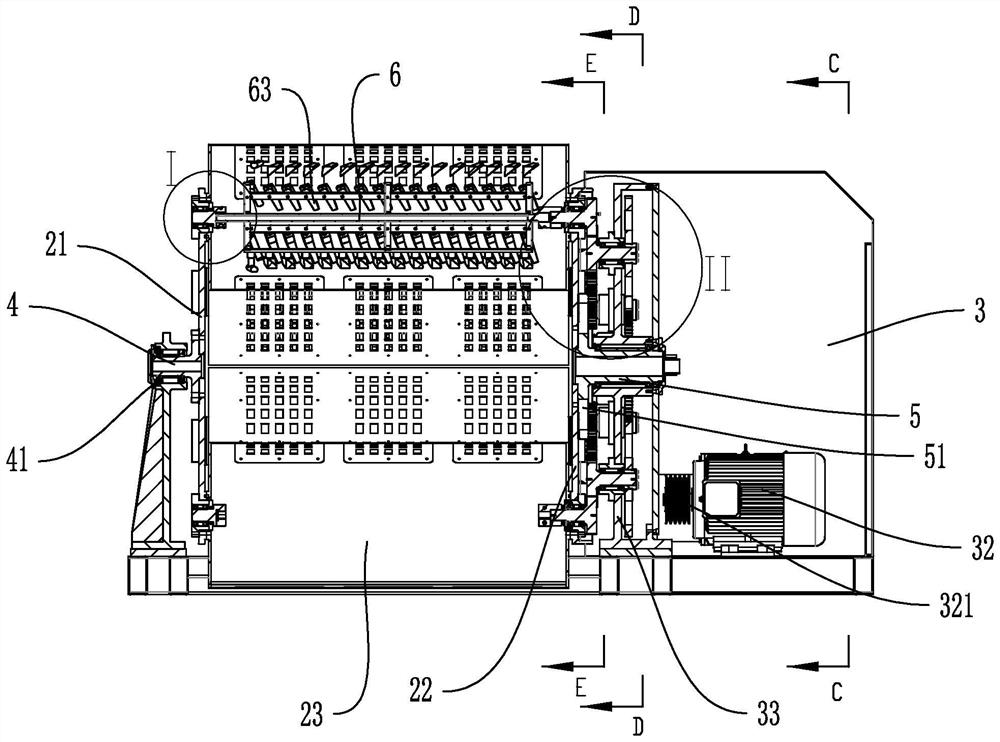

[0045] Embodiment 1, this embodiment discloses a high-efficiency polishing machine with multiple stations, such as Figures 1 to 5 As shown, it includes a frame 1 and a polishing mechanism 2 and a control cabinet 3 positioned on the left and right sides of the frame 1, and the two ends of the polishing mechanism 2 are respectively connected to the frame 1 and the The control cabinets 3 are movably connected to each other, and the polishing mechanism 2 includes a first turntable 21 and a second turntable 22 that are compatible, and a plurality of horizontally arranged polishing rollers 23 are fixedly connected between the first turntable 21 and the second turntable 22, and the polishing rollers 23 The number is set to six groups, and the polishing cylinder 23 includes a fixed cylinder 231 and a movable cover 232 that are detachably connected to each other and a workpiece hanger 6 that is located in the fixed cylinder 231. One end of the fixed cylinder 231 is hingedly connected w...

Embodiment 2

[0052] Embodiment two, this embodiment is on the basis of embodiment one, such as Figures 10 to 12 As shown, a limiting structure 36 compatible with the second turntable 22 is provided on one side of the transmission fixing frame 33, and the limiting structure 36 includes a limiting cylinder 361 and a piston rod fixedly connected with the limiting cylinder 361 The limit rod 362, the second turntable 22 is provided with a limit protrusion 363 that is compatible with the polishing cylinder 23, and the limit protrusion 363 is provided with a limit groove that is compatible with the limit rod 362 , the limiting bosses are evenly distributed around the edge of the second turntable 22 in a circumferential shape, and the outer side of the limiting protrusion 363 is also provided with a reinforcing protrusion integral with it, and the reinforcing protrusion can improve the mechanical strength of the limiting protrusion 363, Prolong its service life; After the limit structure 36 guara...

Embodiment 3

[0054] Embodiment three, this embodiment is on the basis of embodiment two, such as Figure 13 and 14 As shown, the ventilation cavity 9 is formed between the first rotating disk 21, the second rotating disk 22 and a plurality of the fixed cylinders 231, the number of the fixed cylinders 231 is set to six groups, and the second rotating disk 22 and the second The connecting structure 5 is provided with interconnected ventilation slots 221 and ventilation through holes 52, the ventilation through holes 52 are also connected to the control cabinet 3, and the ventilation through holes 52 are also provided with a ventilation gland 53 with a vent. , the control cabinet 3 is provided with a heat dissipation fan 37 suitable for the vent, and a plurality of heat dissipation parts are arranged on the fixed cylinder 231 and the movable cover 232, and the heat dissipation parts cooperate with the ventilation cavity 9. The cover is provided with a metal filter screen fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com