Optical sensor-embedded type artificial muscle and use thereof and preparation method

An optical sensor and artificial muscle technology, applied in the field of soft pneumatic artificial muscles, can solve the problems of increasing the complexity of the design, increasing the size and load of the wearer, and achieving high reusability, light weight, and reduced volume and load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

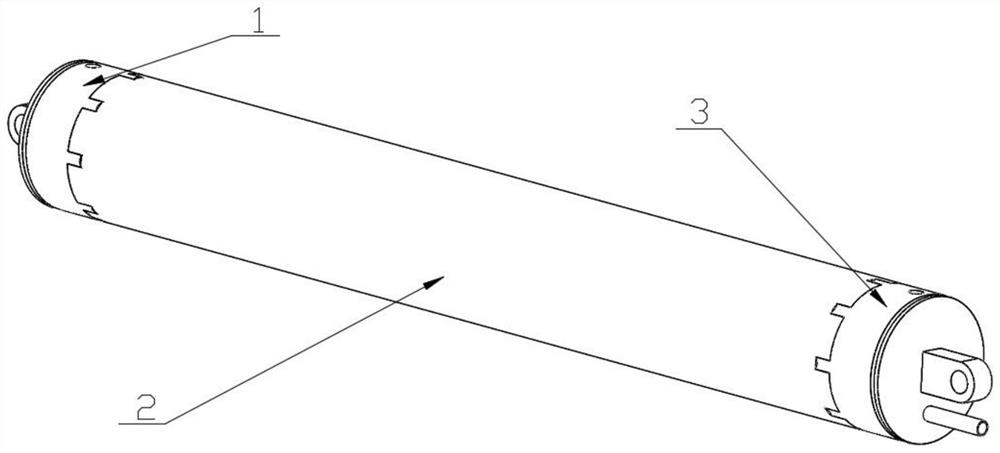

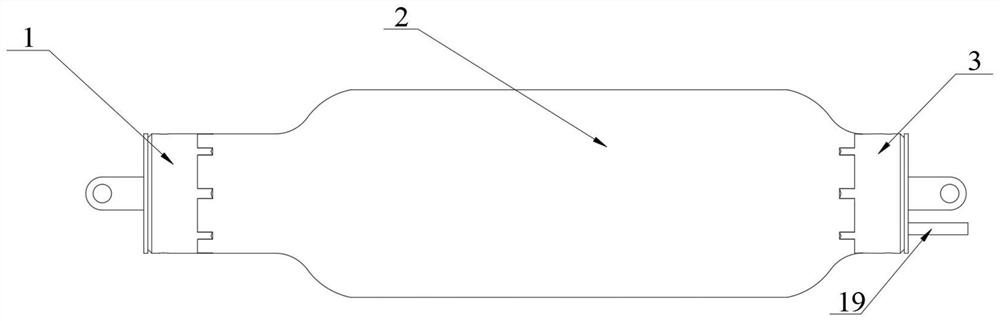

[0044] Such as figure 1 and 2 As shown, a soft pneumatic artificial muscle embedded with an optical sensor includes an optical pressure detection end cap 1 , an artificial muscle matrix 2 and an optical length detection end cap 3 . The artificial muscle matrix 2 is cylindrical, and will expand radially and shorten in length after being filled with gas. The two ends of the artificial muscle matrix 2 are the pressure detection end and the length detection end respectively. The optical pressure detection end cap 1 and the optical length detection end cap 3 are installed on the pressure detection end and the length detection end of the artificial muscle matrix 2 respectively, and are used to detect the internal pressure and the overall length of the artificial muscle matrix 2 respectively.

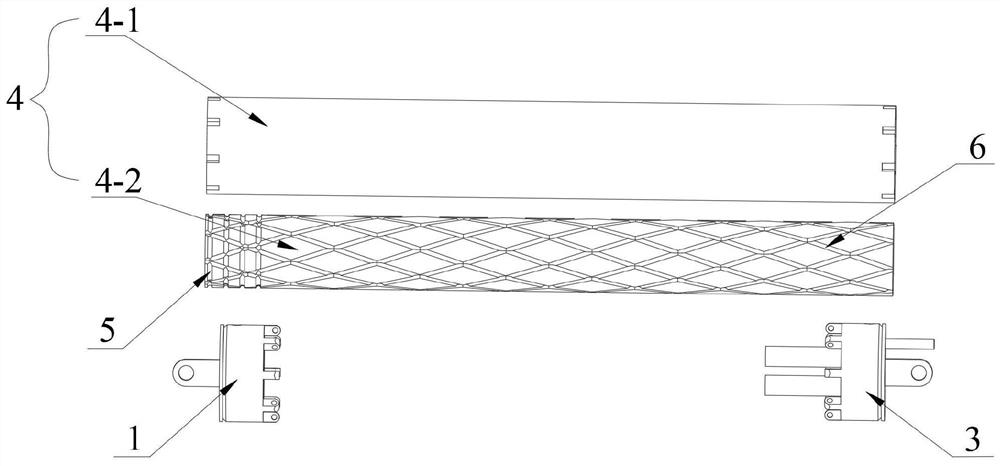

[0045] Such as image 3 and 4a As shown, the artificial muscle matrix 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com