Board slitting equipment

A kind of equipment and strip cutting technology, which is applied in the direction of wood processing equipment, special forming/shaping machines, manufacturing tools, etc., can solve the problem of reduced template cutting efficiency and achieve the effect of easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

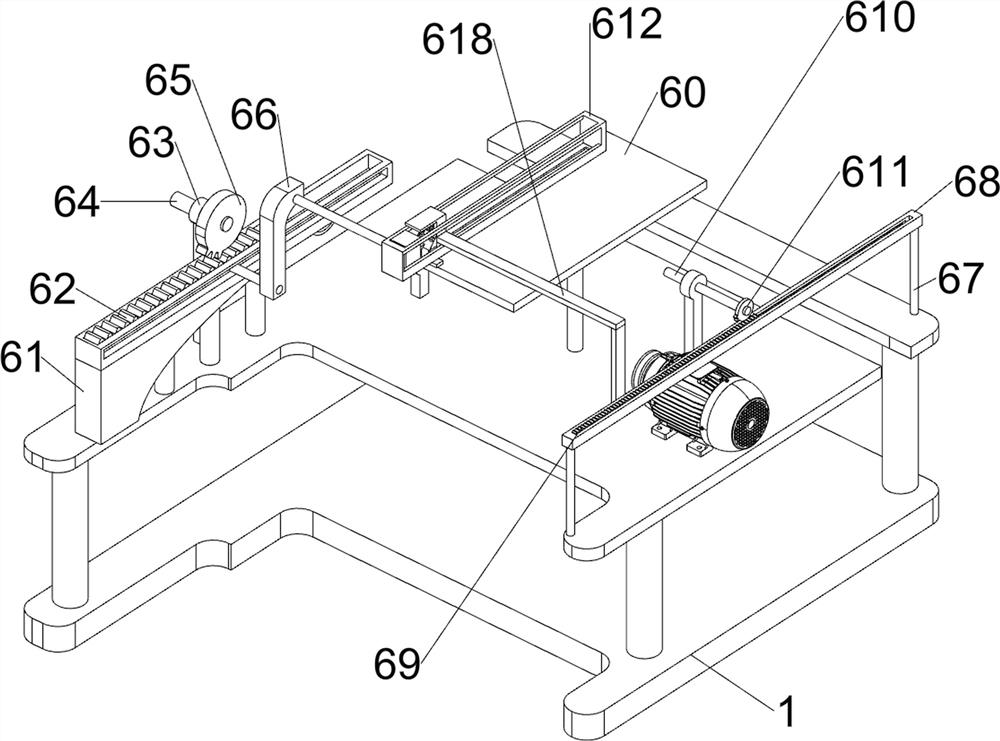

[0024] A kind of plank cutting equipment, such as figure 1 As shown, it includes a base 1, a servo motor 2, a first bearing seat 3, a first rotating shaft 4, a cutting mechanism 5, a propulsion mechanism 6, a first transmission assembly 7, a second transmission assembly 8, a clamping mechanism 9 and a third The transmission assembly 10 is provided with a servo motor 2 in the middle of the upper right side of the base 1, a first bearing seat 3 is provided in the middle of the upper front side of the base 1, a first rotating shaft 4 is connected to the output shaft of the servo motor 2, and a rear side of the upper part of the base 1 is provided. Cutting mechanism 5 is arranged, base 1 top is provided with propulsion mechanism 6, the first transmission assembly 7 is connected with the parts of propulsion mechanism 6 on the left side of first rotating shaft 4, and the second transmission assembly 7 is connected with the parts of propulsion mechanism 6 on the right side of first ro...

Embodiment 2

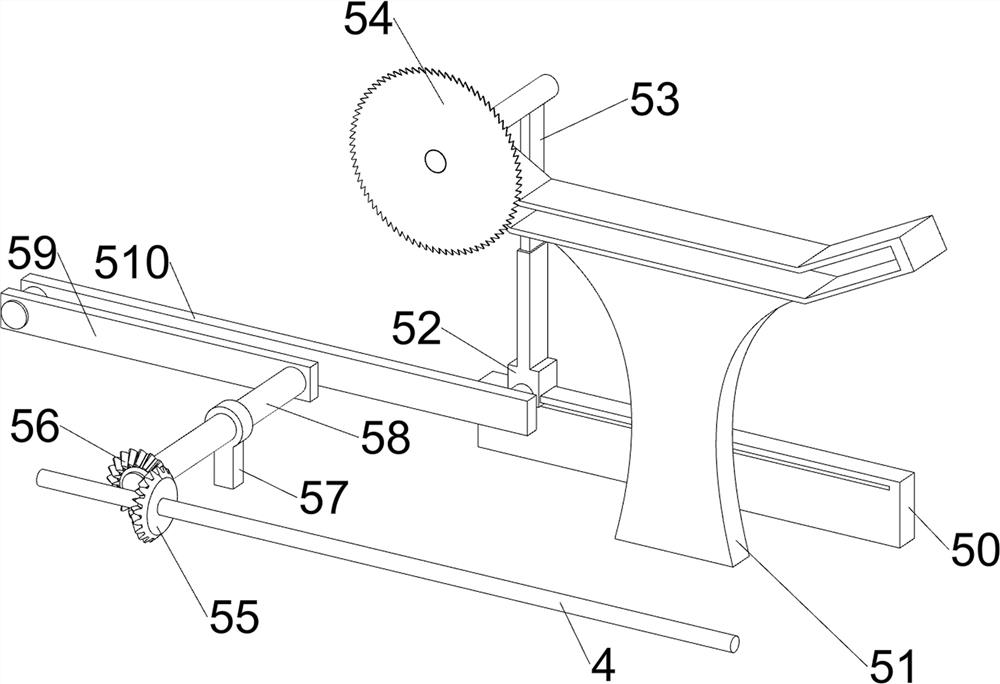

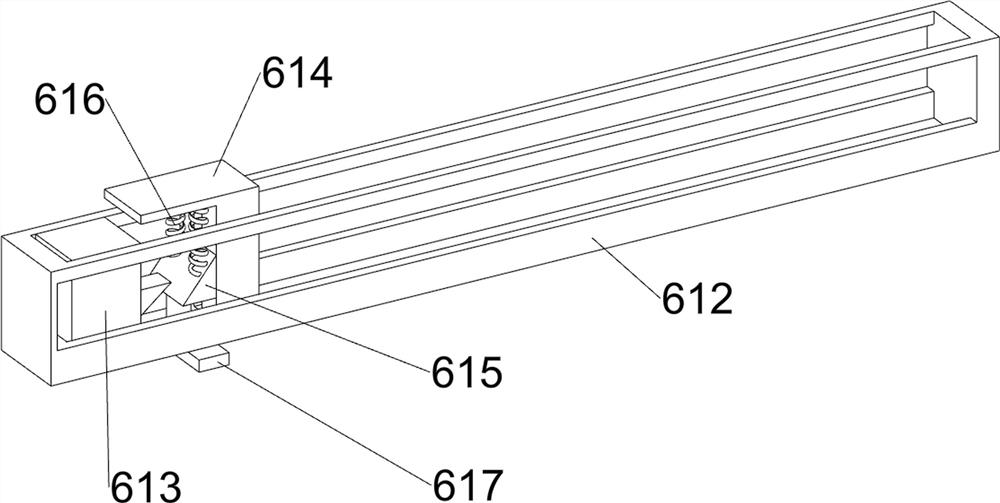

[0027] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the cutting mechanism 5 includes a first slide rail 50, a second slide rail 51, a first slide block 52, a first L-shaped bar 53, an electric saw blade 54, a first bevel gear 55, a second bevel gear 56, The second bearing seat 57, the second rotating shaft 58, the crank 59 and the first connecting rod 510, the base 1 top rear side is provided with the first slide rail 50, the base 1 top rear side is provided with the second slide rail 51, the first slide rail The sliding type in 50 is provided with the first slide block 52, and the sliding type on the first slide block 52 top is provided with the first L-shaped bar 53, and the first L-shaped bar 53 is provided with the electric saw blade 54, and the electric saw blade 54 and the second The slide rail 51 is slidingly connected, the first rotating shaft 4 is provided with a first bevel gear 55, the base 1 top left re...

Embodiment 3

[0034] On the basis of Example 2, such as Figure 7 As shown, it also includes the seventh slide rail 11, the third rack 12, the third spring 13, the fourth missing gear 14, the limit plate 15, the push plate 16 and the connecting plate 17 for pressing down, and the right side of the base 1 top is provided with The seventh slide rail 11 is arranged, and the third rack 12 is slidingly provided in the seventh slide rail 11, the seventh slide rail 11 is connected with the third rack 12 with a third spring 13, and the first rotating rod 610 is provided with a third rack 12. Four missing gears 14, the fourth missing gear 14 meshes with the third rack 12, the right part of the third rack 12 is provided with a connecting plate 17, the upper part of the connecting plate 17 is slidingly provided with a push plate 16 for pressing down, and the second slide rail 51 The front portion is provided with a limiting plate 15, and the limiting plate 15 is slidably connected with the push plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com