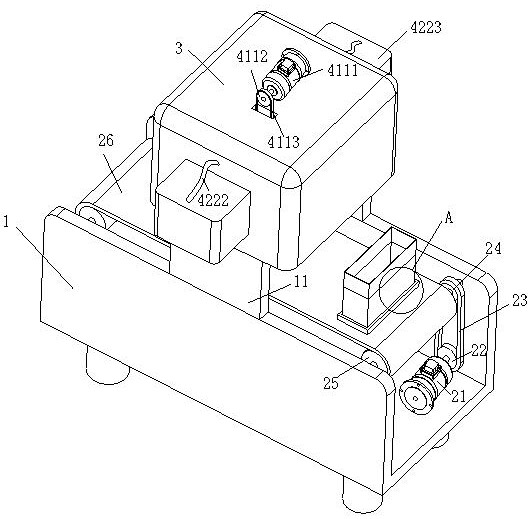

Glass can packing machine

A technology for balers and cans, applied in the field of glass can balers, to improve the overall use effect, reduce the placement space, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

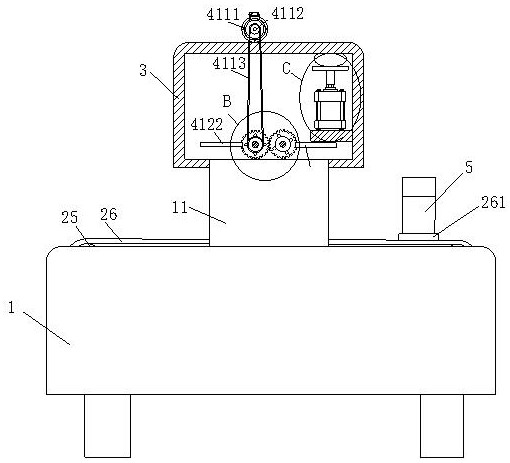

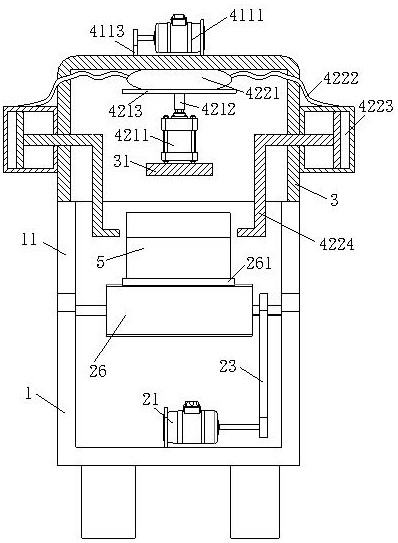

[0024] As an embodiment of the present invention, the first drive assembly 411 includes a second motor 4111, a third pulley 4112, a second belt 4113, and a fourth pulley 4114; the second motor 4111 is mounted on the housing 3. The output end of the second motor 4111 is provided with a third pulley 4112; the fourth pulley 4114 is rotatably connected to the side wall of the housing 3 through a shaft; the third pulley 4112 and the fourth belt The wheels 4114 are connected by a second belt 4113; during operation, the second motor 4111 drives the third pulley 4112 to rotate, which in turn causes the second belt 4113 installed at the output end of the third pulley 4112 to rotate, which plays a role in the second belt 4113 Next, the fourth pulley 4114 rotates.

[0025] As an embodiment of the present invention, the rotating assembly 412 includes a first gear 4121, a straight rod 4122, and a second gear 4123; the first gear 4121 is rotatably connected to the side wall of the housing 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com