Protein one-step directional immobilization method based on Halo-tag specific dehalogenation reaction

A protein and specific technology, applied in the field of protein immobilization, can solve the problems of long period and low specificity, and achieve the effect of solving the long period of protein immobilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

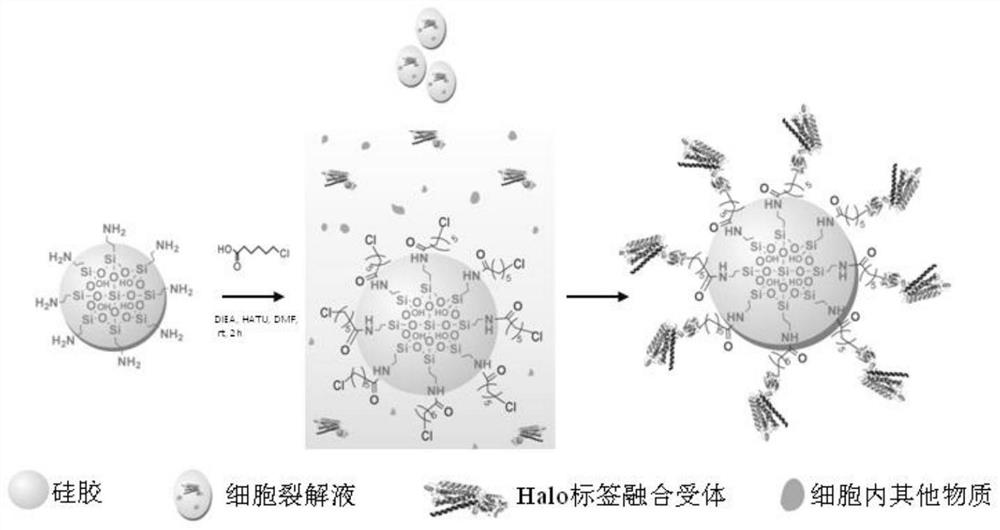

[0034] refer to figure 1 , the one-step directional immobilization method of protein based on Halo-tag specific dehalogenation reaction provided by the present invention, specifically comprises the following steps:

[0035] Step1: Haloalkanoic acid modified separation medium

[0036] Haloalkanoic acids can be selected from: 6-chlorohexanoic acid, 6-bromohexanoic acid, 6-fluorohexanoic acid, 6-iodohexanoic acid and all saturated acids of the above-mentioned halogens.

[0037] The separation medium can be selected: resin microspheres, porous microspheres, etc. modified by functional groups such as hydroxylation, amination, mercaptolation, and carboxylation.

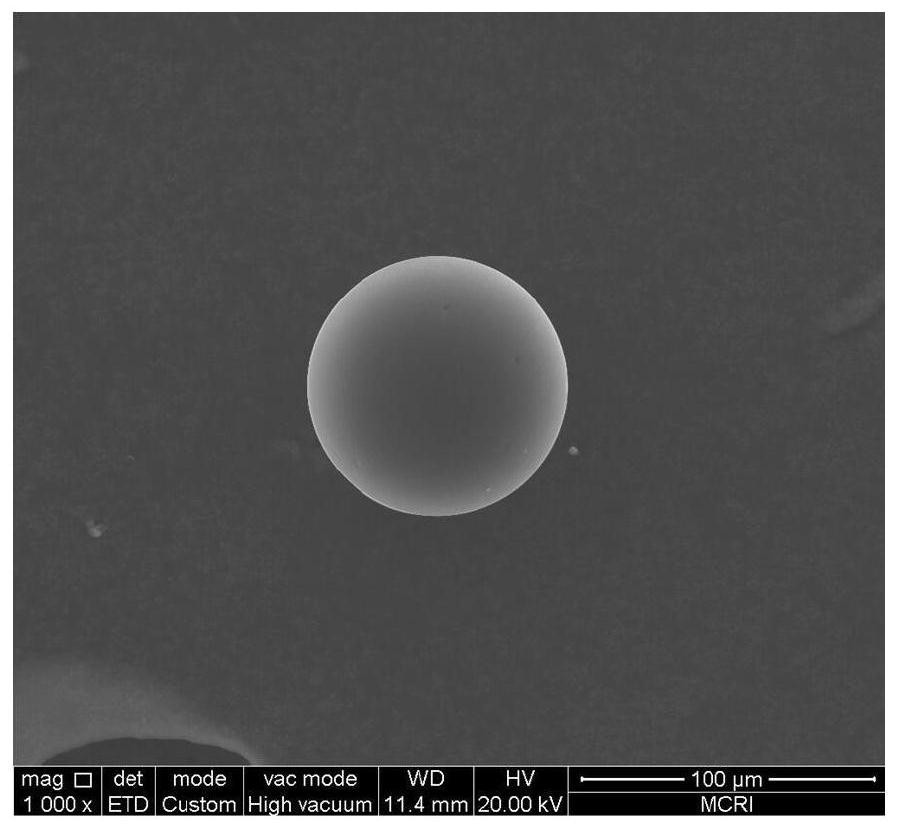

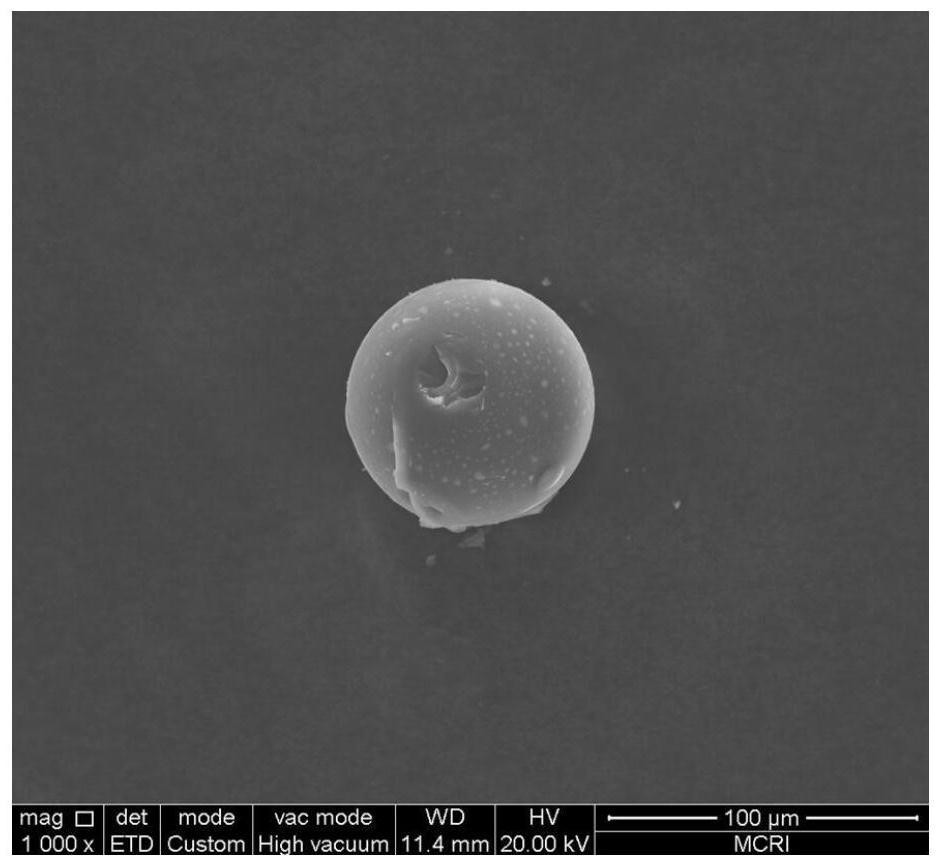

[0038] In this embodiment, 6-chlorohexanoic acid is selected as the halogenated alkanoic acid, and aminated porous microspheres are selected as the separation medium.

[0039] The process of modifying aminated porous microspheres with 6-chlorohexanoic acid is as follows:

[0040] Dissolve 6-chlorohexanoic acid (1.2eq), a...

Embodiment 2

[0047] refer to figure 1, the one-step directional immobilization method of protein based on Halo-tag specific dehalogenation reaction provided by the present invention, specifically comprises the following steps:

[0048] Step1: Haloalkanoic acid modified separation medium

[0049] In this embodiment, 6-chlorohexanoic acid is selected as the halogenated alkanoic acid, and aminated porous microspheres are selected as the separation medium.

[0050] The process of modifying aminated porous microspheres with 6-chlorohexanoic acid is as follows:

[0051] Dissolve 6-chlorohexanoic acid (1.2eq), aminated porous microspheres (1.0eq) and diisopropylethylamine (3.0eq) in DMF (5mL), then add HATU (1.2eq), and stir at room temperature for 2 The 6-chlorohexanoic acid can be modified to the surface of the aminated porous microspheres within hours to obtain the 6-chlorohexanoic acid-modified microspheres.

[0052] Step2: One-step directional immobilization of Halo-tag fusion protein

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com