Zinc dross image recognition and classification method

A technology of image recognition and classification methods, applied in character and pattern recognition, instruments, biological neural network models, etc., can solve the problems of unrecognizable on-site zinc slag pictures, low operation efficiency, low degree of automation, etc., to increase the generalization ability , reduce the workload, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiment of the present application solves the problem of lack of flexibility in visual slag removal in the existing slag removal operation by providing a zinc slag image recognition and classification method.

[0044] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

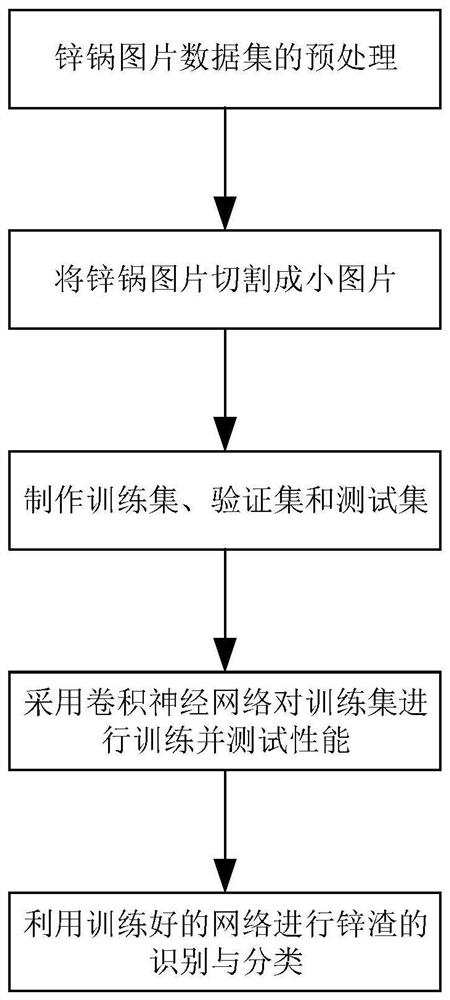

[0045] 1) Preprocessing of the zinc pot image dataset. Due to the complex background of the slag removal scene and the possibility of noise in the captured pictures, it is necessary to denoise the pictures and extract the regions of interest. The gray values of the uninteresting regions in the pictures are all set to 0, and the other regions remain unchanged.

[0046]2) Cut the pretreated zinc pot picture into small pictures and label them. Considering that the on-site visual sensor of the slag removal robot is fixed, and the size of the zinc pot and the actuator of the slag removal robot is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com