Centralized energy storage equipment thermal management system and working method thereof

A thermal management system and technology for energy storage equipment, applied in the field of thermal management systems for centralized energy storage equipment, can solve the problems of unsuitable large-scale power station battery energy storage systems, unified management of temperature control and fire protection, complex system structure, etc., and achieve Improve security and stability, reduce unexpected security problems, and achieve high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

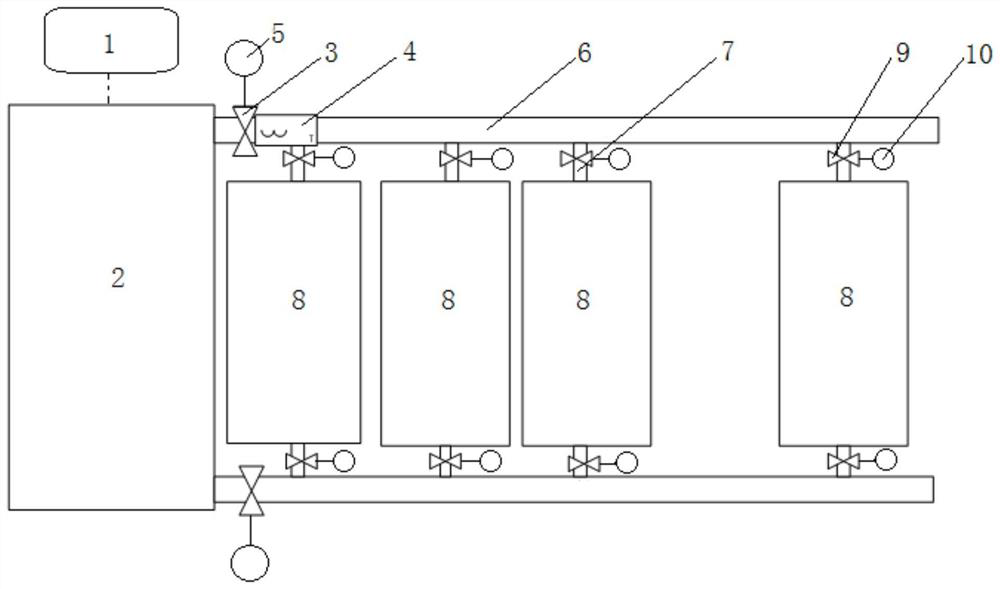

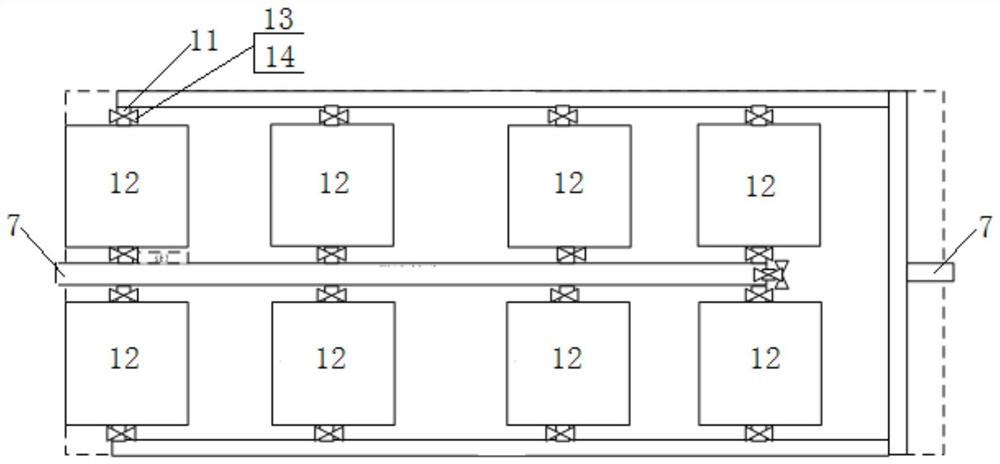

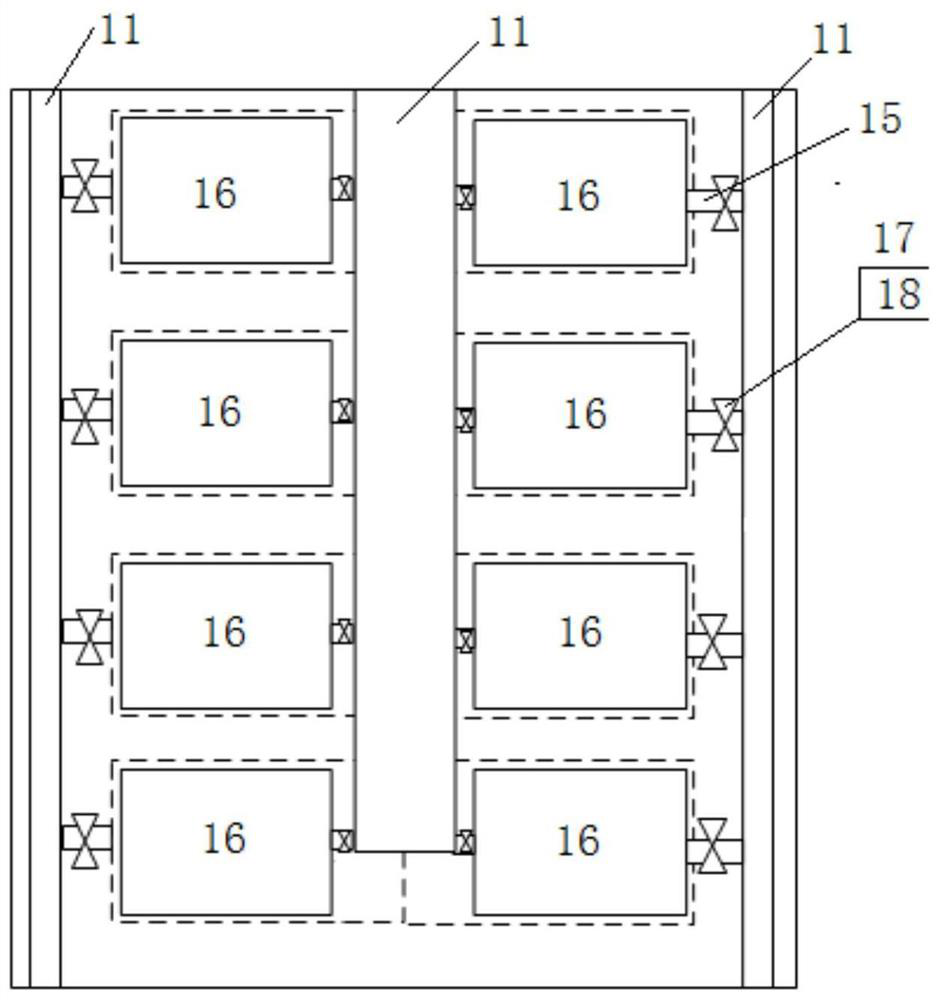

[0032] In the thermal management system of the centralized energy storage device of the present invention, the main circulation road 6 is connected to the main water tank 2, the main circulation water pump 3 is provided on the main circulation road 6, and the main road water pump 3 is connected with the pressure flow detection unit 4 and the temperature measurement of the main road Unit 5; the circulation main road 6 is connected with several circulation branches 7, each circulation branch 7 is connected with an energy storage container 8, the circulation branch 7 is provided with a branch water pump 9, and the branch water pump 9 is connected with a branch test The temperature unit 10; the circulation branch 7 is connected with several circulation branches 11, each circulation branch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com