Tibetan medicine manuoxitang constipation-treating granule and preparation method thereof

A granule and constipation technology, applied in the field of Tibetan medicine, can solve the problems of poor bioavailability, large drug dose, and backward dosage form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

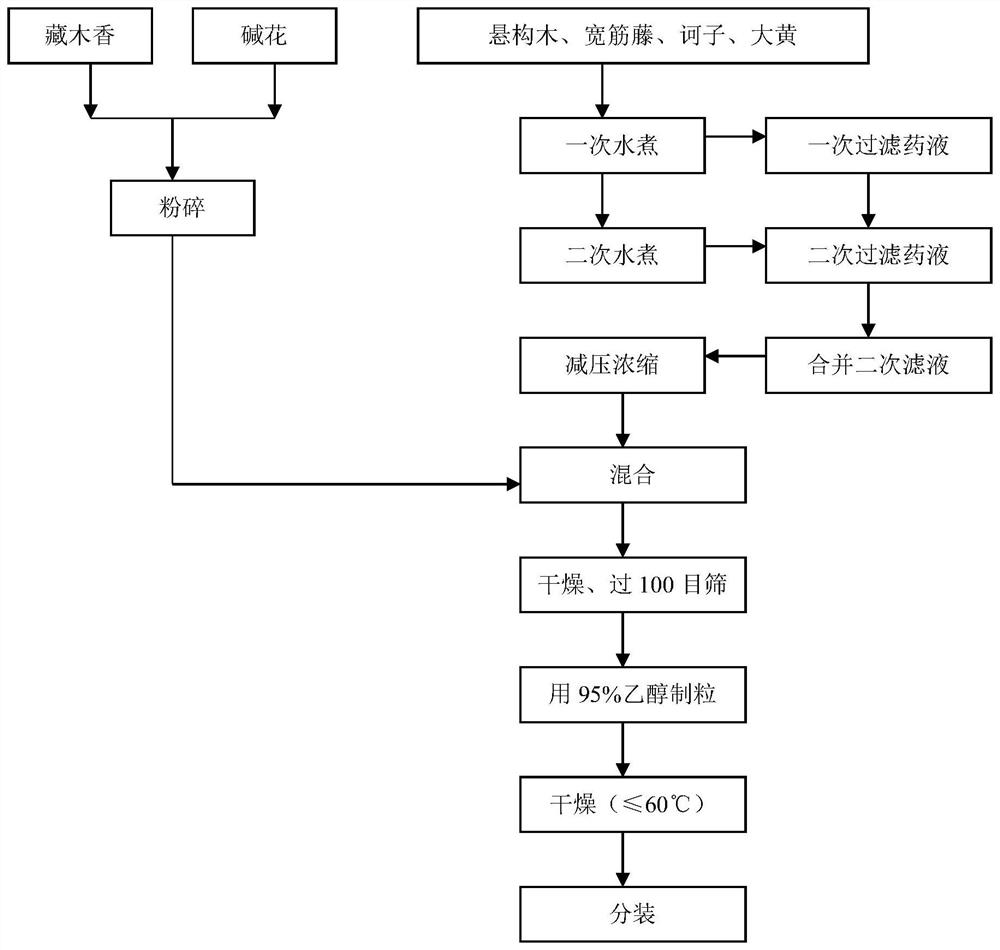

Method used

Image

Examples

Embodiment 1

[0035] The formula of embodiment 1 Manuo system soup constipation-relieving composition

[0036] There are 12 parts of Tibetan woody fragrance, 25 parts of raspberry, 12 parts of broad tendon rattan, 9 parts of myrobalan, 9 parts of rhubarb and 9 parts of alkali flower.

[0037] Preparation Process:

[0038] 1. Raw material pretreatment:

[0039] (1) Zangmuxiang removes impurities, rinses it with running water, and cuts it off; put the alkali flower in water, pour off the upper layer mixed with impurities, and take out the lower layer of precipitated drug alkali flower. The treated Tibetan woody fragrance and alkali flower are respectively dried in the drying room at a temperature of 70°C to 80°C. After drying, they are placed in the irradiation room and sterilized by ultraviolet light. The thickness of the laying is ≤5cm, and every 30 Flip once every minute, and the irradiation time is 300 minutes. The Tibetan woody fragrance and the alkali flower are respectively pulveriz...

Embodiment 2-4

[0051] The formula of Manuo Decoction Constipation Constipation Composition is shown in the following table 1

[0052] The formula (parts by weight) of the constipation-relieving composition of table 1 embodiment 2-4

[0053] herbs Example 2 Example 3 Example 4 Tibetan woody fragrance 10 15 12 raspberry 30 20 25 broad vine 15 12 15 Myrobalan 8 9 10 rhubarb 10 8 9 Alkaline flower 8 10 9

[0054] Preparation process: refer to the method of Example 1.

Embodiment 5

[0055] Embodiment 5 preparation process condition selection

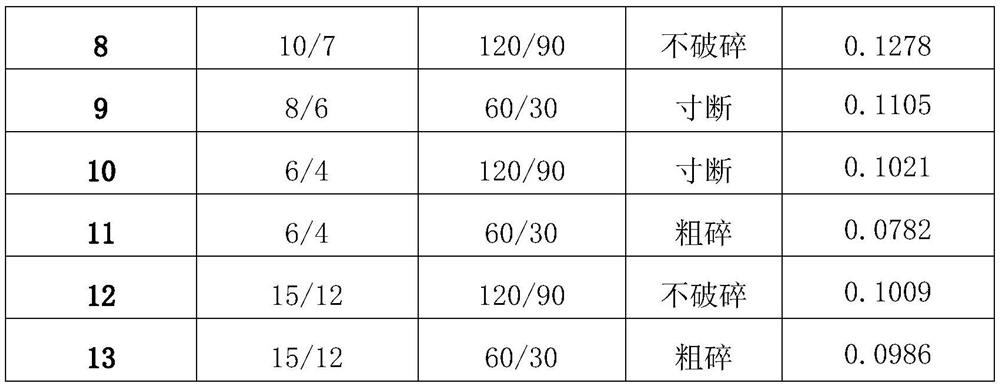

[0056] Because part of the ingredients of this granule is boiled and extracted. In order to maintain the complete extraction of the original ingredients of the medicinal materials, the water boiling extraction conditions are now tested and confirmed. Determine the extraction process that is suitable for actual production, and is more suitable for large-scale batch production of solid instant granules. 2560g raw material, according to the decoction extraction and concentration method of embodiment 1, because what different tests obtain is extractum, there are differences in the degree of concentration, and the data conditions recorded are different. Density d=1.30 is the calculation standard. The influencing factors of the test are: the amount of water for the second boiling, the time, and the degree of brokenness of the medicinal materials. The test results are shown in Table 2.

[0057] Table 2 Analysis table o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com