Multi-mode operated aldehyde removal device

A multi-mode, hand-pressing device technology, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to blow off dust, formaldehyde poisoning, harmfulness, etc., improve efficiency and ensure pressing effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

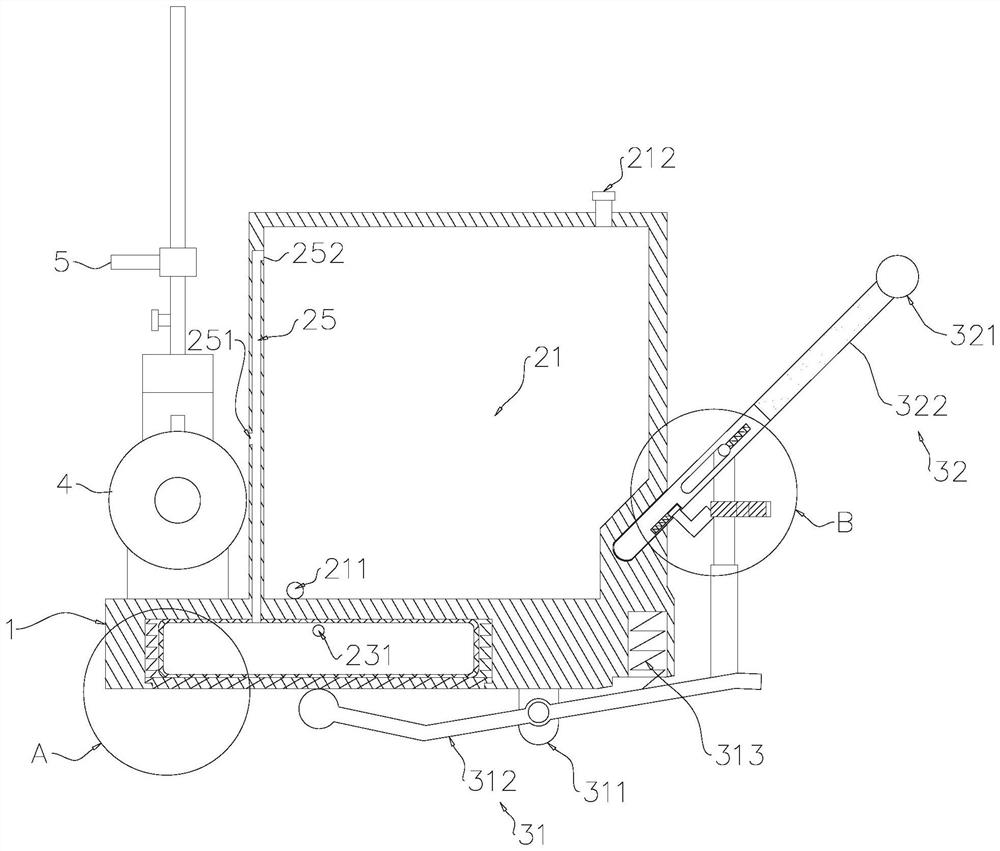

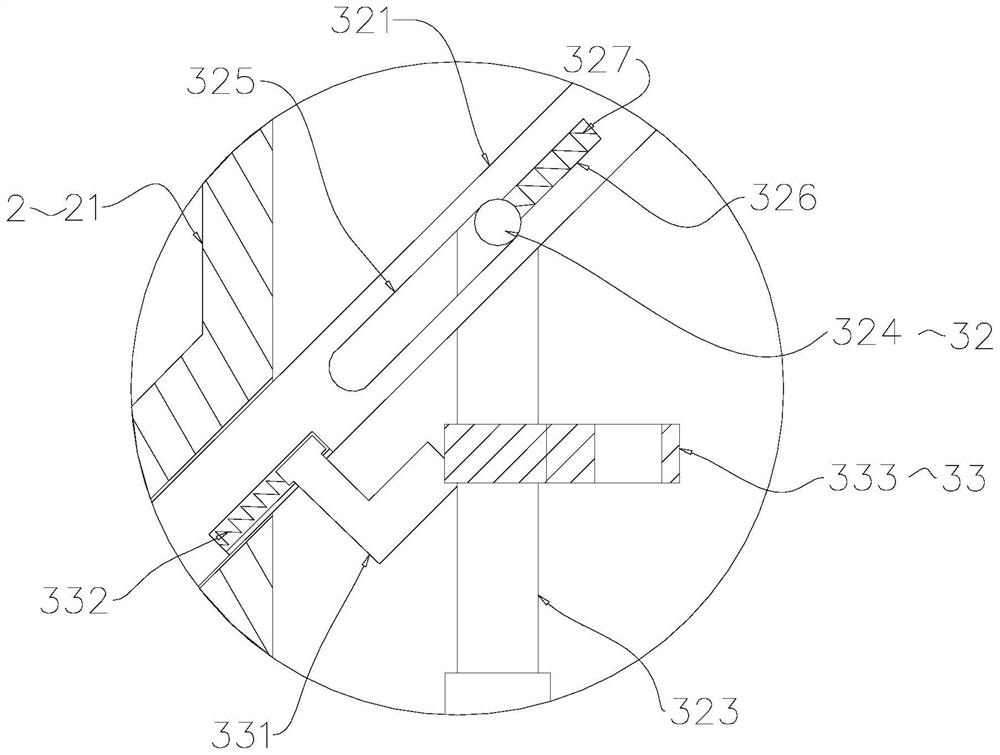

[0040] see Figure 1-6 , a multi-mode aldehyde removal device, including a device main body 1, a storage structure 2, an extrusion structure 3, a tube collection structure 4 and a pipeline structure 5; the storage structure 2 is installed inside the device main body 1 for storing gas and liquid The extruding structure 3 is installed at the lower end of the device main body 1 and can intermittently extrude the storage structure 2 to respectively extrude the gas and liquid in the storage structure 2. At the same time, the extruding structure 3 has two extrusion operation modes: manual and foot. The pipe receiving structure 4 is installed on the upper end of the device main body 1 for storing the pipeline, the pipe structure 5 is installed on the pipe receiving structure 4 and communicated with the storage structure 2, the pipe structure 5 has a gas end and a liquid end, respectively for Evacuation of gases and liquids in the storage structure 2.

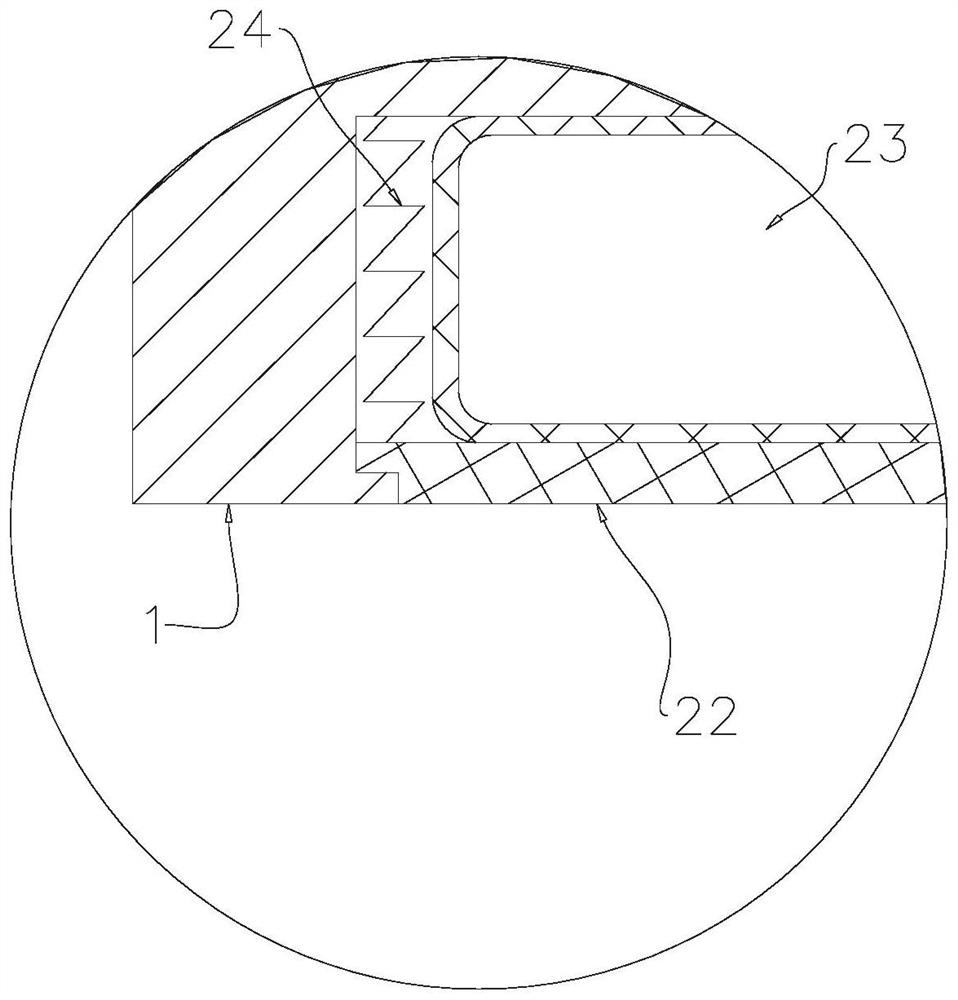

[0041] see Figure 1-2The sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com