A kind of textile slurry stirring structure

A textile slurry and drum technology, applied in mixer accessories, separation methods, filtration separation, etc., can solve problems such as time-consuming, complicated production process, and complicated weaving process, and achieve the effect of improving the quality of use and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

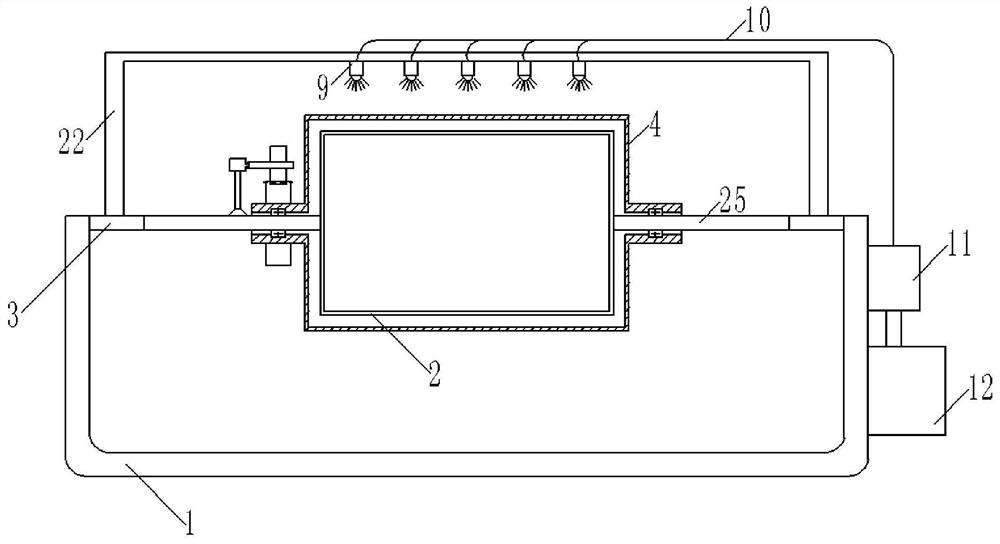

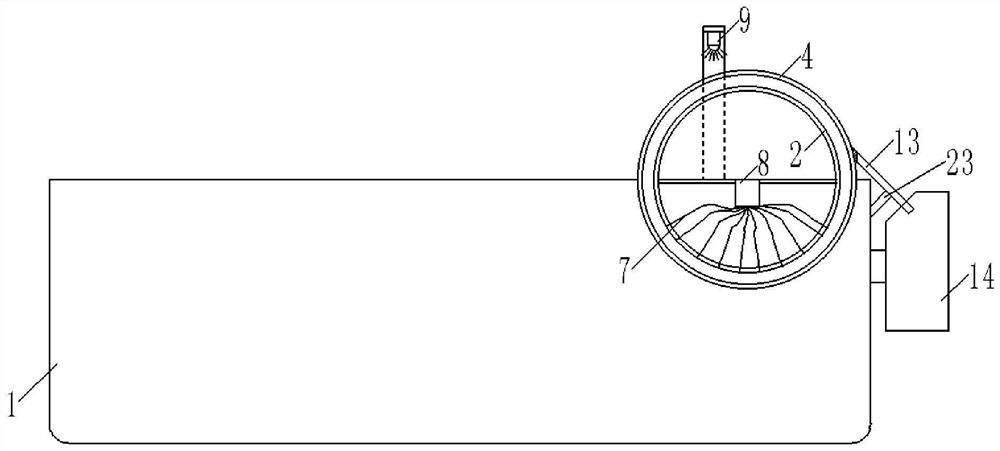

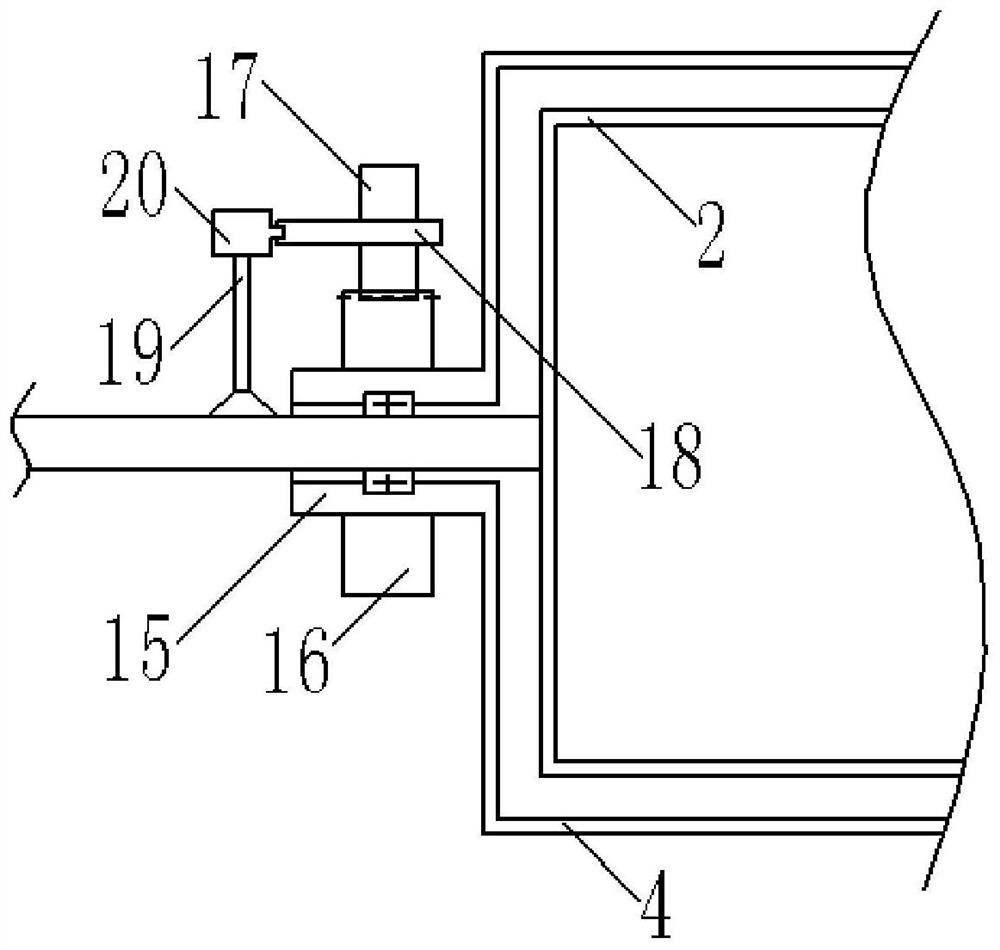

[0034] Embodiment 1: as Figure 1 to Figure 2 As shown, a textile slurry stirring structure includes: a tank body 1, which is used to hold textile slurry; a first drum 2, whose left and right sides are fixed on the tank body 1 by a support frame 3; Rotary cylinder 1 is divided into three fan-shaped areas equidistantly along its axial direction, and the three fan-shaped areas are respectively the suction area located inside the tank body 1, the cleaning area and the filter area located outside the tank body 1; the second Drum 4 is sleeved on the outside of the first drum 2, and its side wall is provided with adsorption components for absorbing impurities such as textile fibers and solid particles in the textile pulp; the suction mechanism is fixed inside the suction area , used to adsorb the impurities inside the textile slurry on the adsorption assembly; the flushing mechanism is located above the cleaning area and fixed on the support frame 3 for washing away the impurities a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com