Grinding wheel with one rough groove and four fine grooves and application thereof

A technology of grooves and grinding wheels, which is applied to bonding grinding wheels, parts of grinding machine tools, and machine tools suitable for grinding the edge of workpieces, etc. Achieve productivity, ensure effectiveness and stability, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

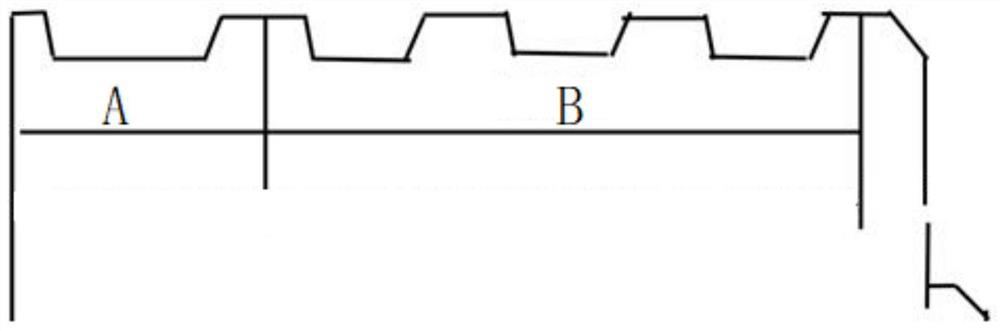

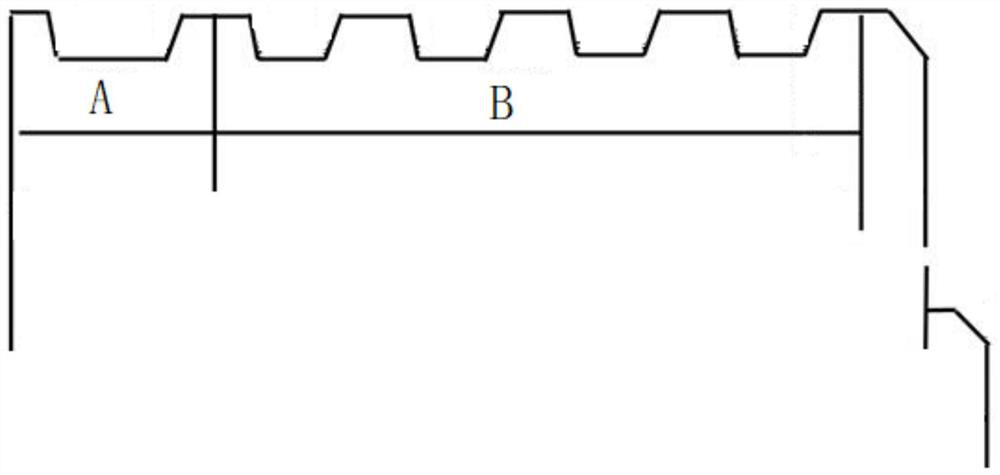

[0027] 1. Design drawing of grinding wheel

[0028] According to the appearance size of the existing grinding wheel, redesign the groove spacing and groove width of the grinding wheel, and rationally optimize the 1 coarse + 3 fine grooves to 1 coarse + 4 fine grooves. The drawings are as follows figure 2 shown.

[0029] The material of the groove is mainly to bond the diamond to the surface of the groove through a binder (mainly composed of Co, Cu, etc.), and to perform chamfering through the contact between the diamond and the surface of the silicon wafer.

[0030] Grinding wheel appearance size: outer diameter 202±0.5mm, thickness 20±0.02mm.

[0031] The rough and fine grinding groove angle is 11±0.5°; the rough and fine grinding groove depth is 1.0±0.1mm.

[0032] The groove spacing and groove width are shown in Table 1:

[0033] Table 1

[0034]

[0035] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com