Stone-like concrete and aluminum rust stone decorative structure manufactured from same

A decorative structure and concrete technology, applied in the field of decoration materials, can solve the problems of EPS line installation is not firm and easy to burn, the line cornice cannot be ideally sealed, the installation is difficult and difficult to disassemble, etc. Destruction, effect three-dimensional full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A stone-like concrete is prepared from the following raw materials in kilograms: 10kg of white cement, 18kg of granite particles, 0.5kg of glue, and 3kg of water.

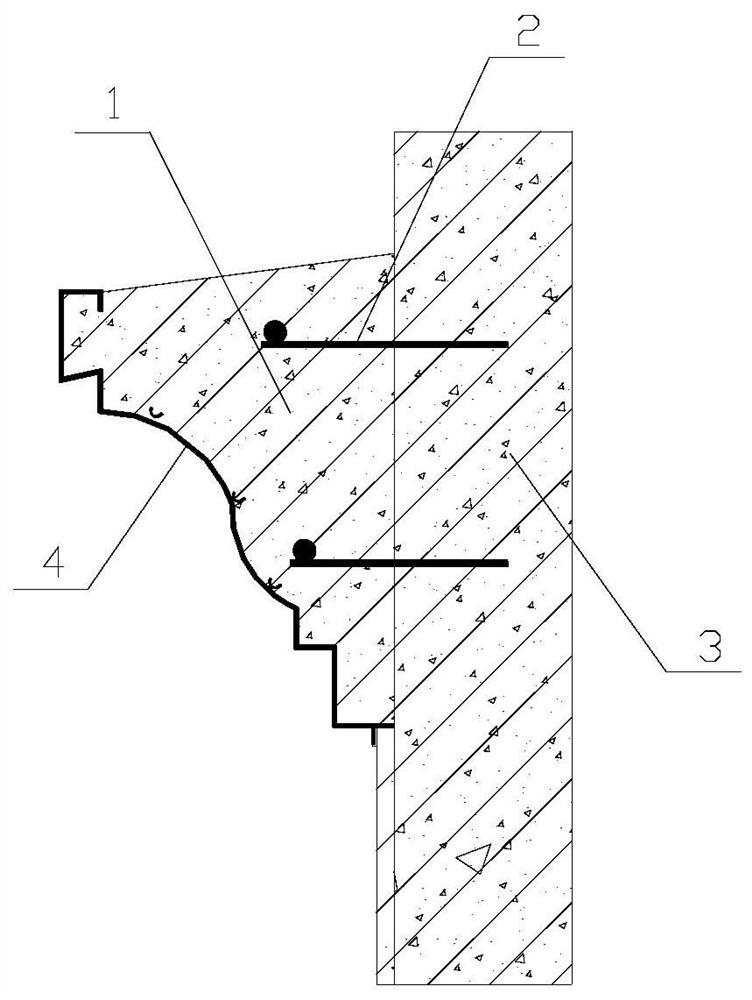

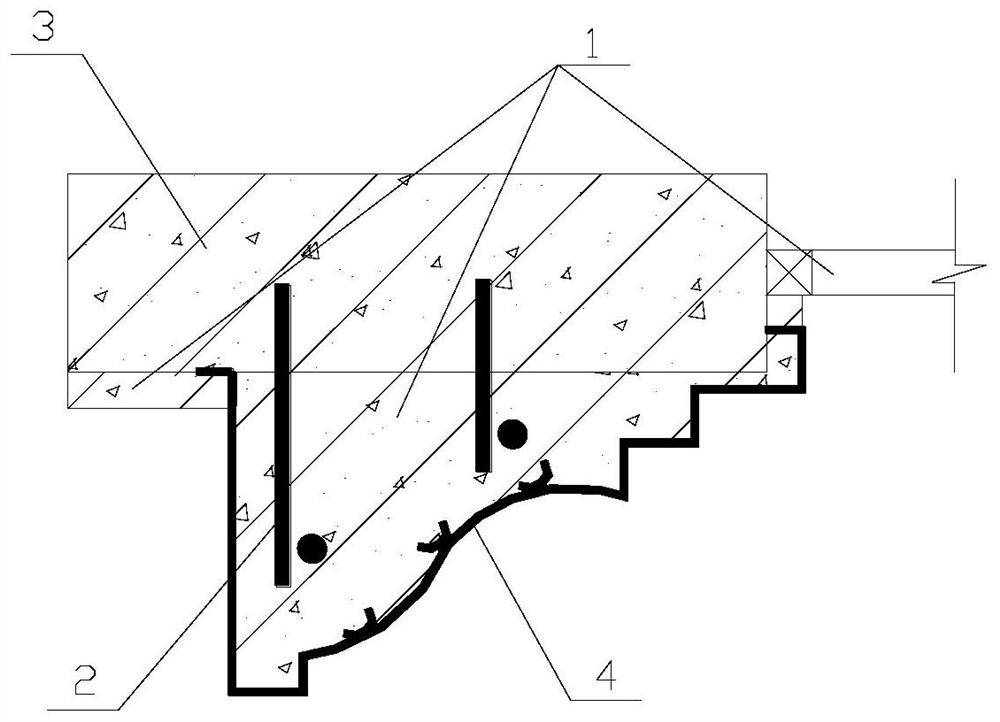

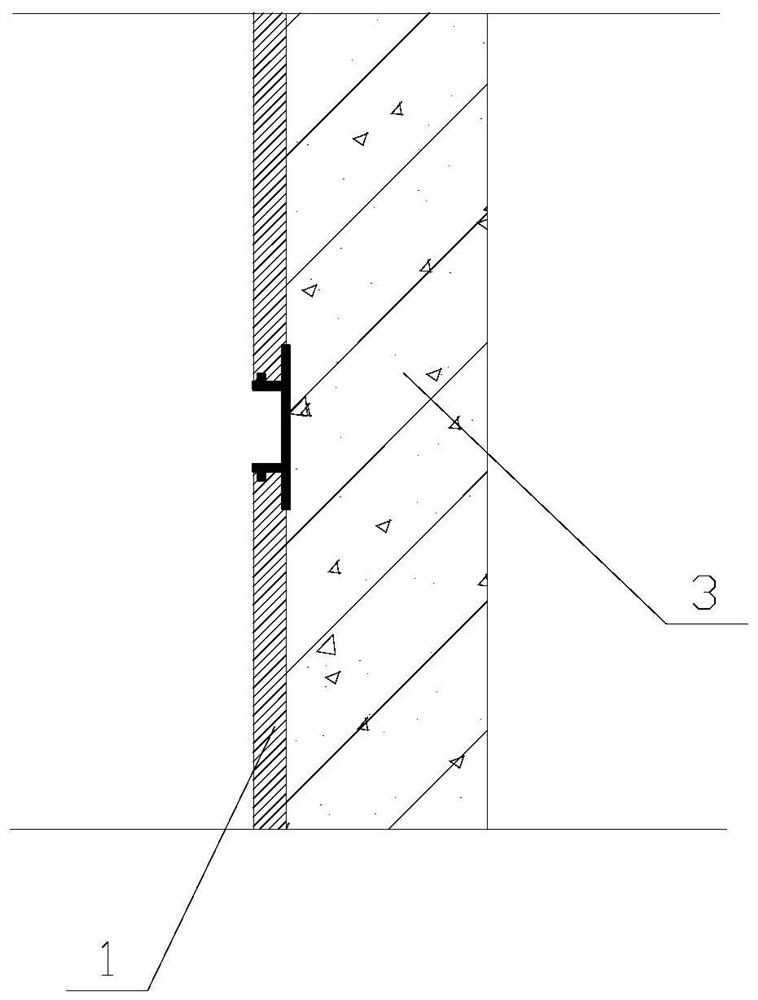

[0019] Such as Figure 1 to Figure 4 As shown, the decorative structure of aluminum stone made of stone-like concrete includes S-shaped line shell, stone-like concrete 1 and decorative veneer; the wall thickness of the S-shaped line shell is 0.2-0.5mm; the decorative veneer is fixed on the outer wall of the S-shaped line shell On the top, the decorative layer uses the selected color surface as the final finish of the line. The color can be customized according to the needs of use. The surface is smooth and round, long-lasting dirt-resistant, and the shape can be designed arbitrarily; stone-like concrete is filled in the S-shaped line shell.

[0020] After the pouring is completed, the visible surface is processed into a stone-like surface by chiseling, chopping, etc.

[0021] The S-shaped line shell 4 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com