A self-cleaning garbage truck

A garbage truck and self-cleaning technology, which is applied in garbage collection, garbage cleaning, garbage receptacles, etc., can solve the problems of difficult cleaning and labor-intensive problems of garbage trucks, reduce manpower, improve cleaning efficiency, and achieve efficient and fast cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

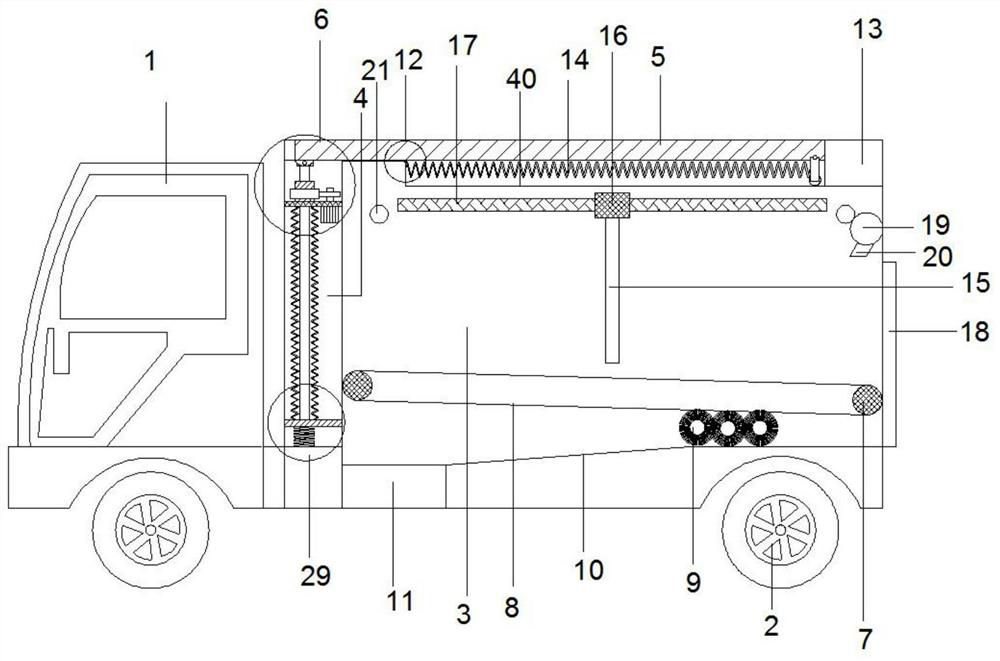

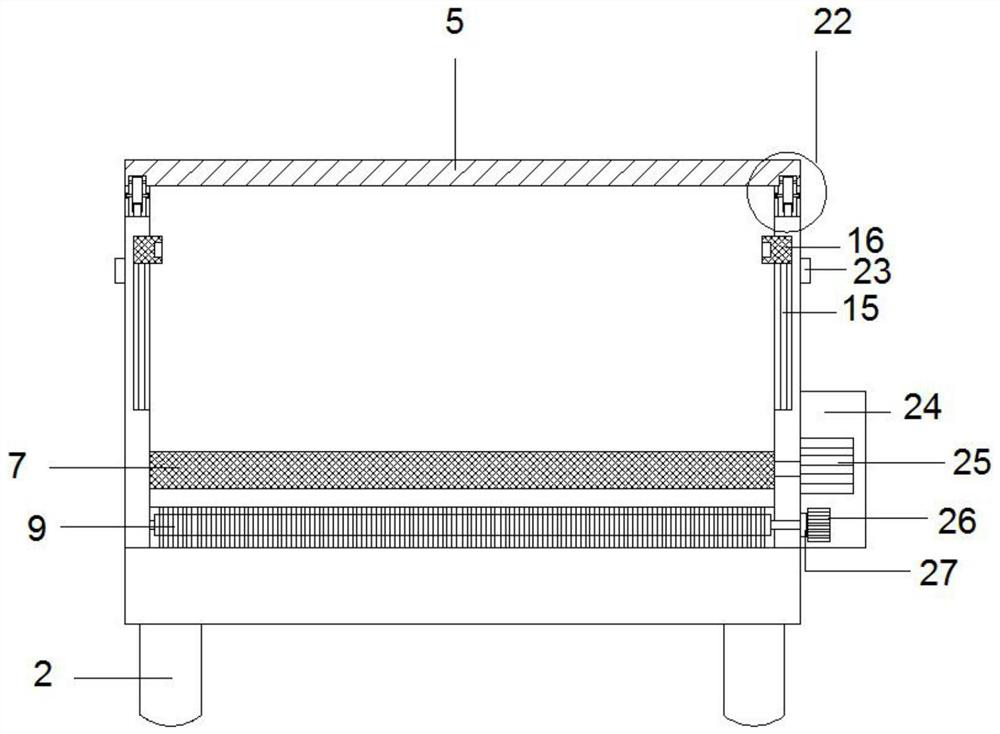

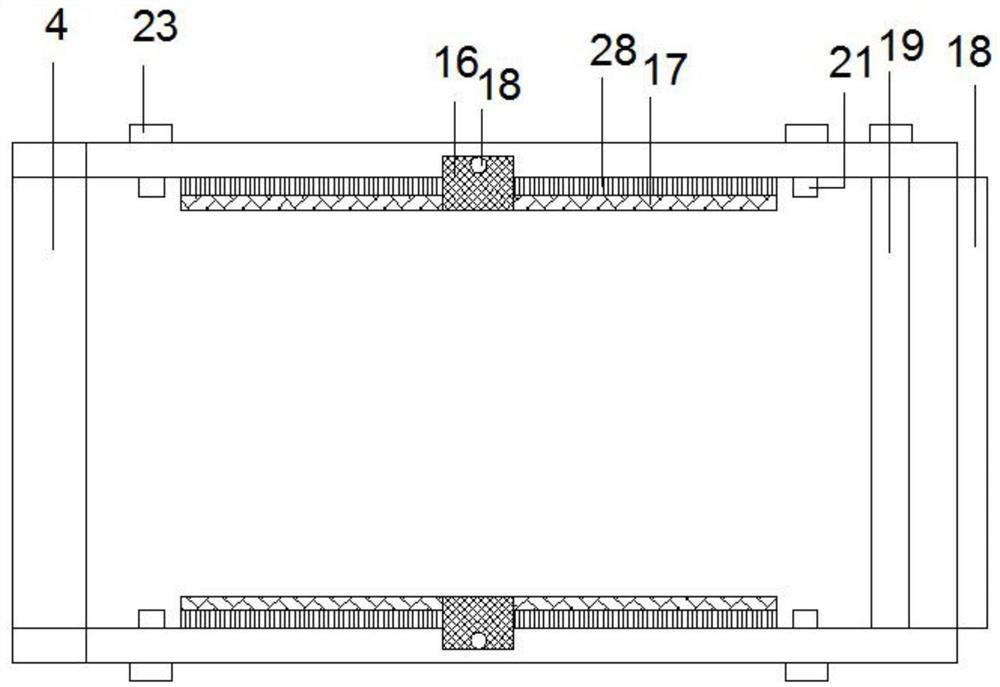

[0030] refer to Figure 1-7 , a self-cleaning garbage transporter, comprising a head 1, tires 2 and a carriage 3 connected behind the head 1, the tires 2 are arranged below the head 1 and the carriage 3, and side panels 13 are provided on the front and rear sides of the carriage 3 , a cover plate 5 is arranged above the carriage 3, a first chute 40 is arranged in the center of the upper end of the side plate 13, and a sliding mechanism 22 is arranged at the lower end of the right side of the cover plate 5 to be slidably connected with the first chute 40, and the first chute 40 The left end of the interior is connected with the sliding mechanism 22 through the first elastic member 14. A protective layer 4 is provided on the side of the carriage 3 close to the head 1, and a lifting mechanism 6 is provided on the inner upper end of the protective layer 4. The lifting mechanism 6 includes The screw 30, the fixed plate 31 and the rotating sleeve 32, the fixed plate 31 is fixed on t...

Embodiment 2

[0038] like Figure 1-7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, electric guide rails 15 are symmetrically arranged inside the side plates 13 on the front and rear sides of the carriage 3, and the electric guide rails 15 are embedded inside the side plates 13, and the electric guide rails 15 are covered An electric sliding sleeve 16 is provided, and the electric sliding sleeve 16 is provided with a horizontal brush 17 symmetrically on both sides, and the horizontal brush bristles 28 on the horizontal brush 17 are slidably connected to the surface of the side plate 13 . In order to further clean the side panels 13 of the compartment 3 .

[0039] Working principle: When filling garbage, start the third motor 34, so that the second gear 33 drives the rotating sleeve 32 to rotate, so that the screw 30 drives one end of the cover plate 5 to rise, and the other end slides with the side plate 13 to open the top of the carriage 3 to remove the garba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com