Steam aerated concrete stirring equipment and use method

A technology for mixing equipment and concrete, which is applied in the field of steam aerated concrete mixing equipment, can solve the problems of large floor space, complicated procedures, complicated operation equipment procedures, etc., achieve high practicability, ensure consistency, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

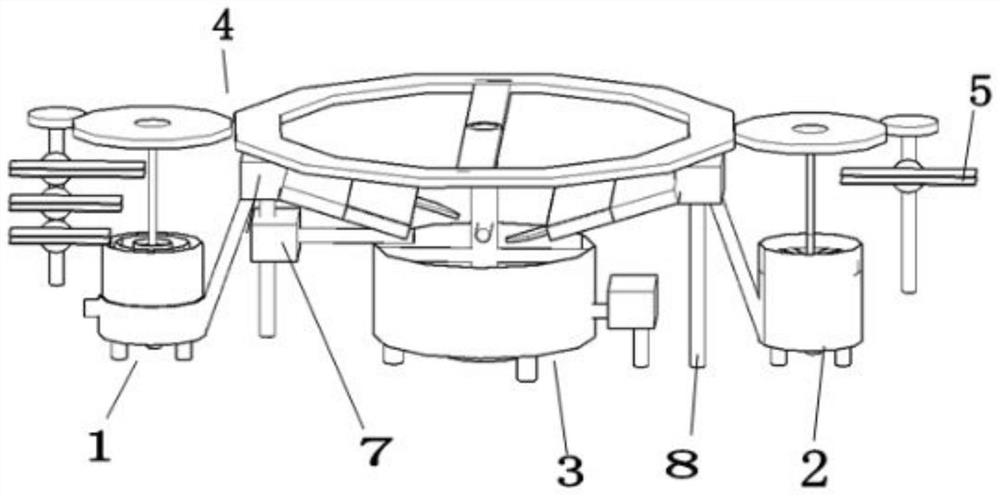

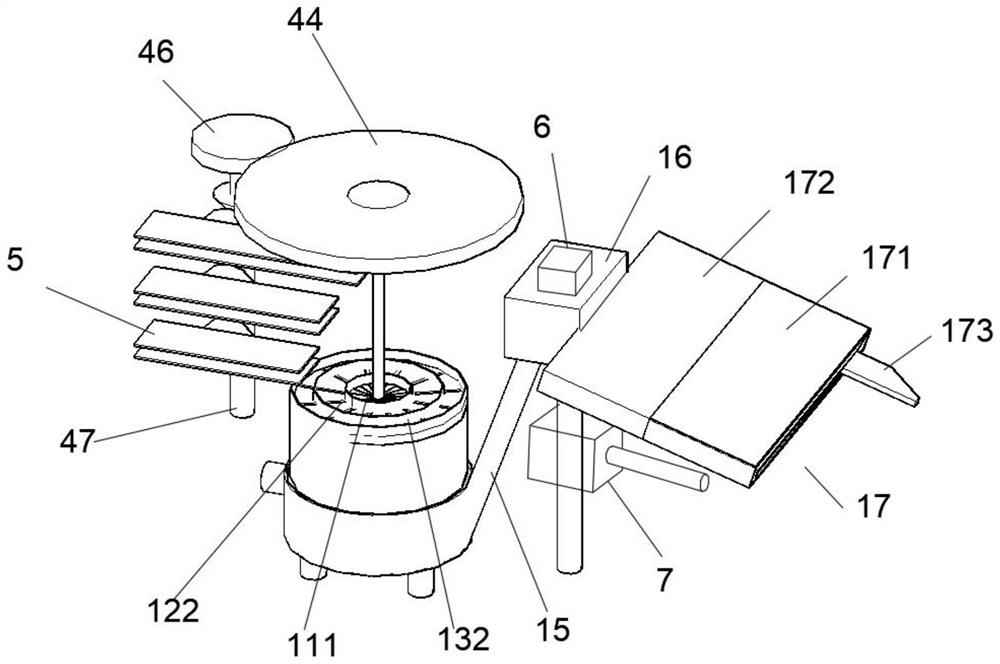

[0052] Such as Figure 1-8 Shown, is an embodiment of the present invention, a kind of steam aerated concrete mixing equipment,

[0053] Such as Figure 1-3 As shown, the slurry device 1 is a device that mixes bottom skin waste, sand, gypsum and water to make a slurry, and then quantitatively transports it to the mixing device 3;

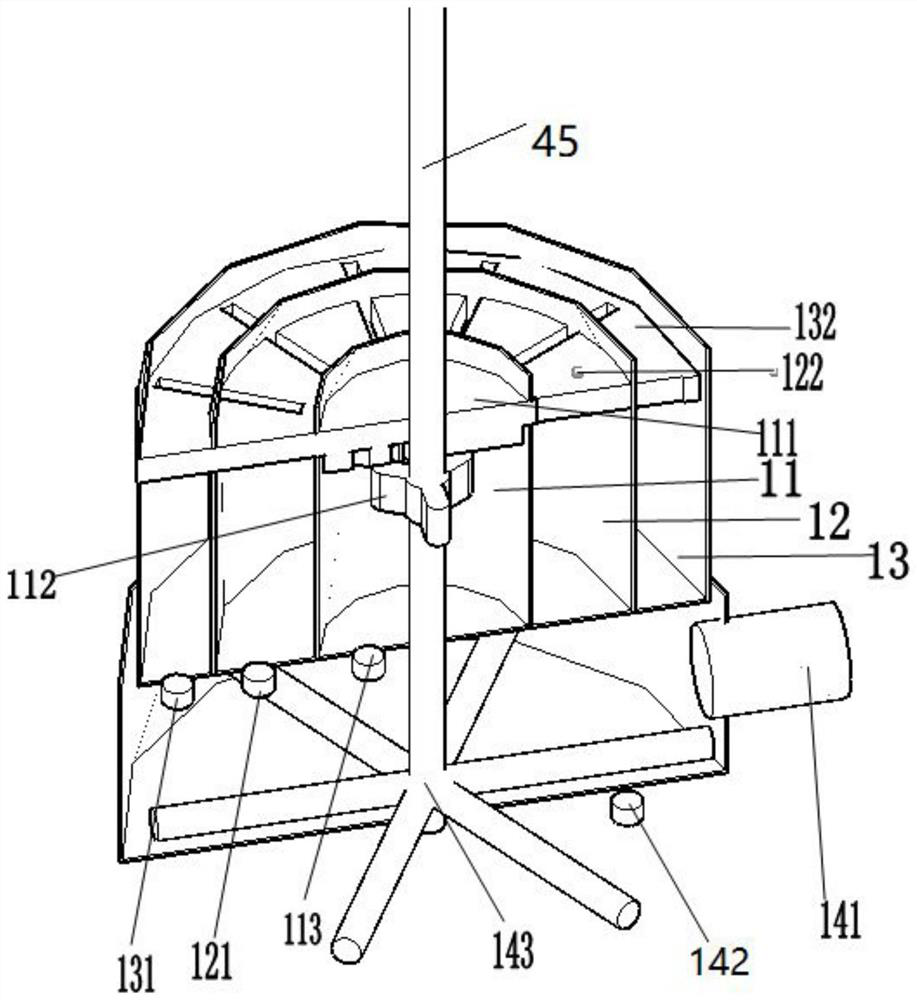

[0054] The first bin body 11 is cylindrical, the central axis is vertically provided with a first auxiliary shaft 45, a grinding piece 111 is arranged on the top of the first bin body 11, and a waste material fan 112 is arranged inside the first bin body 11. The powder made by the grinding part 111 can be inhaled faster, the outlet 113 of the bin is set at the bottom of the first bin 11, and the opening and closing is controlled by the computer;

[0055] The second warehouse 12 is set on the periphery of the first warehouse 11, the upper part is open, the lower part is sealed, the top is provided with a grinding disc 2 122, and there is a computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com